The Nylon Recovery Strop is a game-changer in the realm of off-road and heavy industrial rescues and towing operations. Designed to deliver unparalleled strength and reliability, this innovative strop is equipped with embedded thimbles, setting it apart from traditional webbing straps and kinetic recovery nylon ropes. Its rugged construction and resistance to dirt, mud and abrasion make it an indispensable tool where performance and durability are paramount.

Advantage:

Traditional soft eye connections and detachable shackles found in conventional recovery ropes can be susceptible to wear and tear, compromising their strength and longevity. However, Juli Nylon Recovery Strop eliminates this concern by integrating galvanized thimbles directly into its body. This innovative design not only enhances the strop's tensile strength but also ensures that it remains resilient in the face of challenging conditions.

Main Features:

The abrasion/cut resistant rubber shields the inner nylon fibers from environmental factors, effectively preventing the intrusion of oil, water, mud, and dust. This feature not only minimizes maintenance but also elevates its durability above that of other fabric straps.

High strength Nylon 7T/9T load core with high strength to weight ratio

Highly flexible and lightweight, making it ideal for accessing confined spaces and attaching devices.

Designed for easy installation, featuring galvanized thimbles embedded within the rubber casing. It is perfectly compatible with shackles and clevis pins.

Product Usage:

The common scenarios for using off-road vehicle rescue ropes include the following:

Vehicle Stuck: When an off-road vehicle gets stuck in mud, sand, snow, or other terrain obstacles, the recovery strop can be used to connect the stranded vehicle to a rescue vehicle for towing it out of the stuck.

Vehicle Drop or Cliff Edge: If an off-road vehicle accidentally approaches a cliff edge, the strop can be used to securely connect the vehicle to another vehicle.

Vehicle Breakdown: In the event of mechanical failure or inability to continue driving, the strop can be used to tow the vehicle to a repair point or a safe area.

Deep Water Crossing: When an off-road vehicle needs to cross deep water areas, the recovery strop can be used to stabilize the vehicle and provide traction.

**In these rescue scenarios, the correct use of the recovery stropis crucial. It is important to ensure the selection of the appropriate rope type and load capacity, and to follow the correct connection and operation procedures to ensure the safety of the rescue. Additionally, rescue personnel should have sufficient operational experience to make the right judgments in emergency situations.

Specifications

| Nylon Recovery Strop | |||||||||||||

| Specification | Diameter | Process | Usage | Operating environment | |||||||||

| 9t*10M | Φ25 | Twisting | Coiling | Resin Infusion | Correctly use a soft buckle of 9T or more and a metal buckle of 5T or more to attach the vehicle, and try to clear underneath the vehicle (mud, sand, snow, etc.) if it has been bottom out. Have at least 3 meters of acceleration distance for elastic rescue. Before connecting the strop, make sure that it is not damaged, make sure that you do not let the strop come into contact with hot surfaces or sharp objects, and do not let it get knotted and twisted. | Nylon recovery strop should avoid repeated friction on sharp or overheated surfaces, and need to rest for a period of time between uses to return to their original length and strength.Overuse in a short period of time can lead to heat buildup in the load-bearing fibers, which can affect product performance. | |||||||

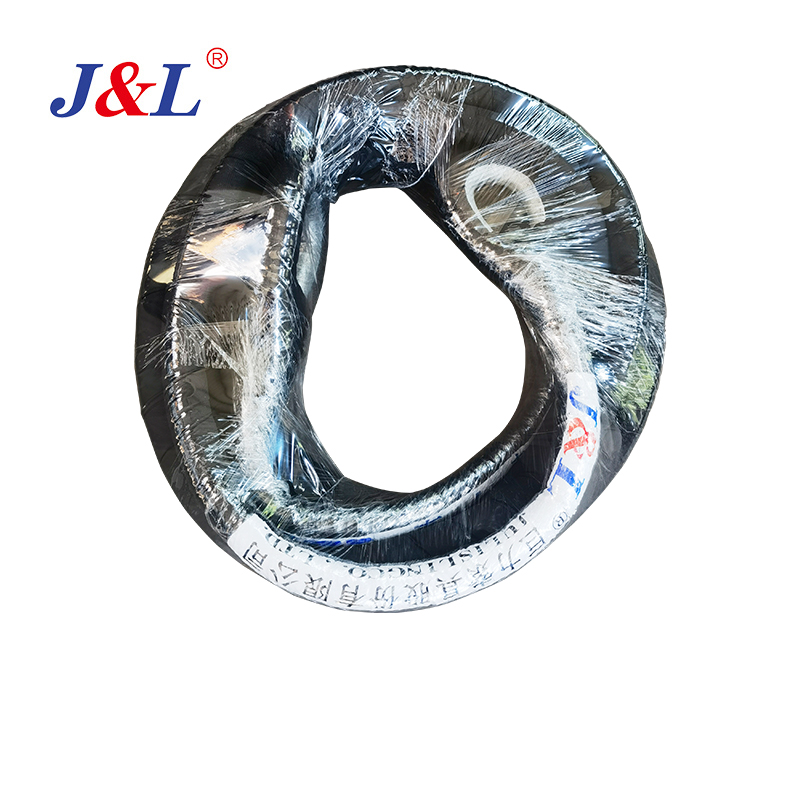

Package

FAQ

Q1:Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history. Focusing on research and development and manufacturing of rigging.

Q2:What is your terms of delivery?

Accept EXW, FOB, CIF, etc. If you have any other choices or requirements, we could negotiate it together to help you find the most convenient and favorable one.

Q3:How does your factory do regarding quality control?

Quality is priority. We always attach great importance to quality controlling. Skillful workers care every details during the production; Strict quality testing in each process; Authoritative testing reports can be provided for customer.

Q4:What payment method is available?

By T/T, L/C, Other methods can be negotiated together.

Download Document

Whether is a product enquiry or technical help, please send messager here, our team will respond within 24-48 hours.