Mooring Rope

Description

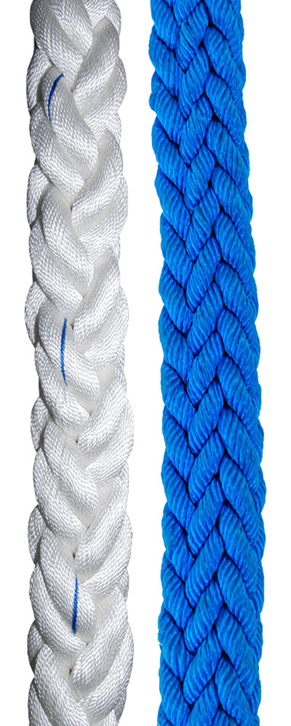

1. Production Scope: The structure of mooring rope can be divided into 3-strand. 6-strand, 8-strand and 12-strand.

2. Diameter scope: Ф6mm ~ Ф140mm

3. Raw material: polypropylene, polyester, nylon, Super high tensile strength polyethylene, aramid fibre and synthetic fibre.

4. Characteristics: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easy to operate, etc.

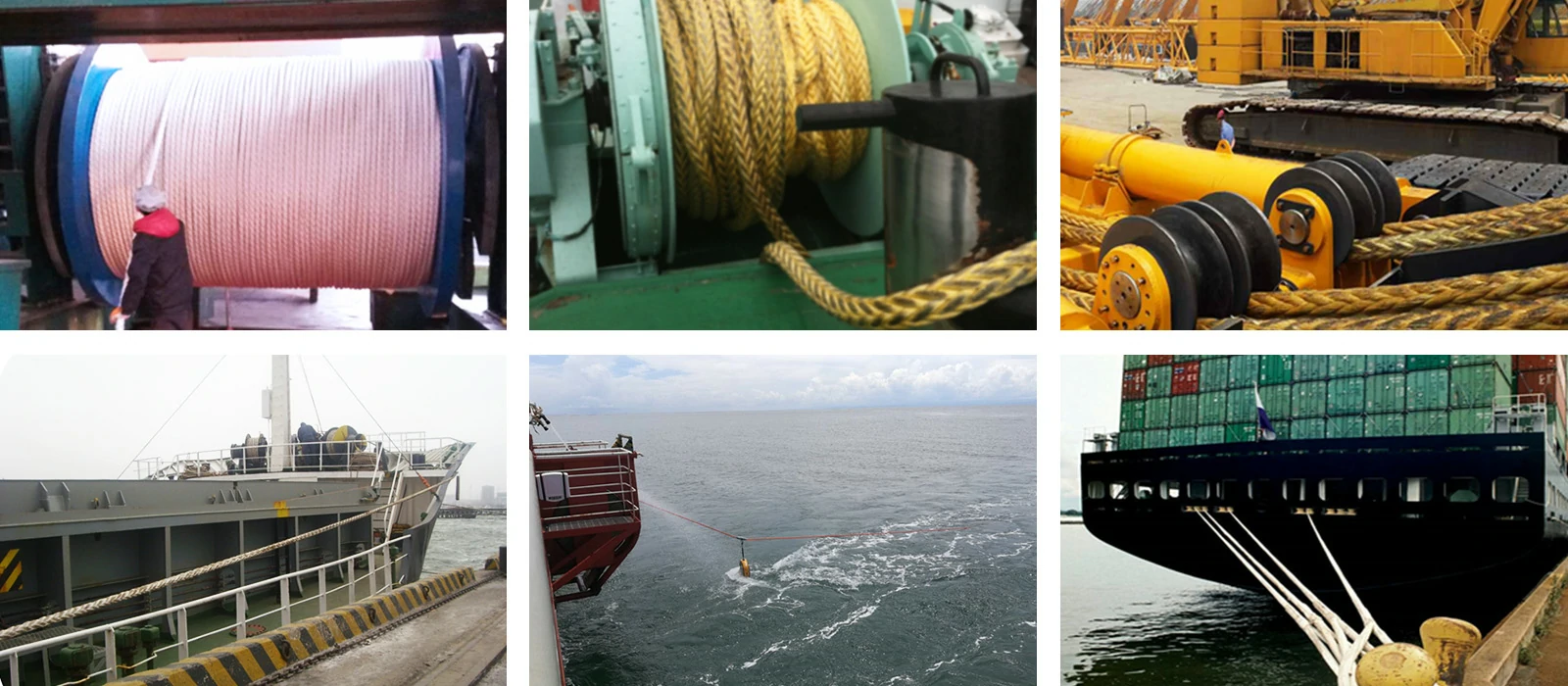

5. Usage: mainly used in shipping equipment, fishing industry, port operation, ocean transportation, electric construction, oil exploration, national defense and sports goods, etc.

Mooring ropes Features

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easy to operate, etc.

Mooring ropes Usage

Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

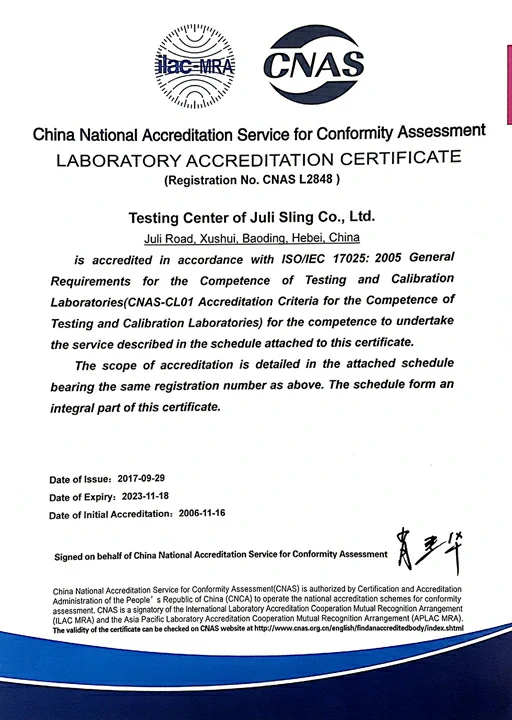

Juli Sling is a leading supplier of high-quality rigging products with 38 years of experience. As the only CNAS-approved test laboratory in the rigging industry, our Juli Sling Testing Center utilizes advanced electro-hydraulic servo horizontal tensile testing machines to provide comprehensive inspection services for metallic materials, synthetic fiber ropes, and lifting devices. We adhere to rigorous quality management standards, holding numerous certifications including ISO9001, ISO14001, and various international safety certifications. Our diverse product range includes polyester webbing slings, round slings, ratchet straps, steel wire ropes, and rigging equipment, earning us a reputation for reliability and efficiency in the market.

If you have any specific questions or need more information on a particular type or use case, contact us!

Specifications

| 8-Strand and 12-Strand PE fiber Mooring Rope | |||||||

|

Diameter (mm) |

Circumference (INCH) |

Linear density(Ktex) | Deviation(%) | Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 20 | 2-1/2 | 232 | ±5 | 46.4 | 380 | 340 | |

| 22 | 2-3/4 | 281 | ±5 | 56.2 | 450 | 400 | |

| 24 | 3 | 331 | ±5 | 66.2 | 520 | 470 | |

| 26 | 3-1/4 | 384 | ±5 | 76.8 | 600 | 540 | |

| 28 | 3-1/2 | 445 | ±5 | 89 | 680 | 610 | |

| 30 | 3-3/4 | 506 | ±5 | 101.2 | 770 | 690 | |

| 32 | 4 | 575 | ±5 | 115 | 870 | 780 | |

| 34 | 4-1/4 | 648 | ±5 | 129.6 | 960 | 860 | |

| 36 | 4-1/2 | 720 | ±5 | 144 | 1040 | 940 | |

| 38 | 4-3/4 | 798 | ±5 | 159.6 | 1160 | 1040 | |

| 40 | 5 | 881 | ±5 | 176.2 | 1260 | 1130 | |

| 44 | 5-1/2 | 1060 | ±5 | 212 | 1460 | 1310 | |

| 48 | 6 | 1250 | ±5 | 250 | 1700 | 1530 | |

| 52 | 6-1/2 | 1460 | ±5 | 292 | 1970 | 1770 | |

| 56 | 7 | 1690 | ±5 | 338 | 2260 | 2030 | |

| 60 | 7-1/2 | 1930 | ±5 | 386 | 2530 | 2280 | |

| 64 | 8 | 2200 | ±5 | 440 | 2840 | 2560 | |

| 68 | 8-1/2 | 2480 | ±5 | 496 | 3170 | 2850 | |

| 72 | 9 | 2780 | ±5 | 556 | 3520 | 3170 | |

| 76 | 9-1/2 | 3090 | ±5 | 618 | 3890 | 3500 | |

| 80 | 10 | 3430 | ±5 | 686 | 4300 | 3870 | |

| 88 | 11 | 4170 | ±5 | 834 | 5200 | 4680 | |

| 96 | 12 | 4970 | ±5 | 994 | 6180 | 5560 | |

| 104 | 13 | 5800 | ±5 | 1160 | 7180 | 6470 | |

| 112 | 14 | 6730 | ±5 | 1346 | 8280 | 7460 | |

| 120 | 15 | 7720 | ±5 | 1544 | 9440 | 8500 | |

| 128 | 16 | 8790 | ±5 | 1758 | 10670 | 9610 | |

| 136 | 17 | 9920 | ±5 | 1984 | 11930 | 10750 | |

| 140 | 17-1/2 | 10510 | ±5 | 2102 | 12560 | 11320 | |

| Product: PE fiber mooring rope of eight-strand and twelve-strand are produced after resin treatment of the yarn with the international advanced technique. Protection sleeve can be added according to customer's requirements, which can improve the wear-resistant capacity. As to the strength, it is higher than the steel wire rope with the same diameter, but the weight is only 15% of the wire rope. Low elongation at 3.5-4.5%. Density is 0.97g/cm³, which can make sure it can float on the water. Soft, UV-resistant, good bending and anti-fatigue capacity, fatigue resistance strength is 1,000 times of that of steel wire rope and Nylon rope. Application field: mooring, anchoring, lifting sling, towage, military industry, ocean oil, and ocean transportation, etc. |

|||||||

| 8-Strand and 12-Strand Monofilament Polypropylene (pp) Mooring Rope | |||||||||

|

Diameter (mm) |

Circumference (INCH) |

Linear density (Ktex) |

Deviation (%) |

Theoretical weight (kg/200M) |

Min.Breaking load(Monofilament) | Min.Breaking load(Multifilament) | ||

| (KN) | (Ton) | (KN) | (Ton) | ||||||

| 20 | 2-1/2 | 180 | ±5 | 36 | 64 | 6.53 | 56.9 | 5.81 | |

| 24 | 3 | 260 | ±5 | 52 | 89.6 | 9.14 | 79.7 | 8.73 | |

| 28 | 3-1/3 | 355 | ±5 | 71 | 119 | 12.14 | 104.9 | 10.7 | |

| 32 | 4 | 463 | ±5 | 92.6 | 154 | 15.7 | 132.3 | 13.5 | |

| 36 | 4-1/4 | 586 | ±5 | 117.2 | 191 | 19.48 | 165.9 | 16.93 | |

| 40 | 5 | 723 | ±5 | 144.6 | 233 | 23.76 | 201 | 20.51 | |

| 44 | 5-1/2 | 875 | ±5 | 176 | 278 | 28.35 | 241.5 | 24.64 | |

| 48 | 6 | 1040 | ±5 | 209.8 | 327 | 33.35 | 280.4 | 28.61 | |

| 52 | 6-1/2 | 1220 | ±5 | 244 | 379 | 38.65 | 324.5 | 33.11 | |

| 56 | 7 | 1420 | ±5 | 284 | 436 | 44.47 | 371 | 37.86 | |

| 60 | 7-1/2 | 1630 | ±5 | 326 | 495 | 50.49 | 424.2 | 43.29 | |

| 64 | 8 | 1850 | ±5 | 370 | 558 | 56.92 | 480 | 48.98 | |

| 72 | 9 | 2340 | ±5 | 468 | 692 | 70.58 | 602.7 | 61.5 | |

| 80 | 10 | 2900 | ±5 | 580 | 850 | 86.7 | 741.3 | 75.64 | |

| 88 | 11 | 3510 | ±5 | 702 | 1010 | 103.02 | 889.5 | 90.77 | |

| 96 | 12 | 4170 | ±5 | 834 | 1190 | 121.38 | 1050 | 107.14 | |

| 104 | 13 | 4890 | ±5 | 978 | 1380 | 140.76 | 1204.4 | 122.9 | |

| 112 | 14 | 5670 | ±5 | 1134 | 1580 | 161.16 | 1390 | 141.84 | |

| 120 | 15 | 6500 | ±5 | 1300 | 1800 | 183.6 | 1596 | 162.86 | |

| 128 | 16 | 7400 | ±5 | 1480 | 2040 | 208.69 | 1801.8 | 183.86 | |

| 136 | 17 | 8400 | ±5 | 1680 | 2290 | 233.58 | 2028.6 | 207 | |

| 140 | 17-1/2 | 8890 | ±5 | 1778 | 2405 | 245.3 | 2144.5 | 218.83 | |

| Product: Breaking load capacity can meet the high grade requirements of IS01346-2012. Light density, good floatability, nonabsorbent, wear-resistant, chemical corrosion resistant, good electrical insulating property, good antimicrobial property, will never go mouldy and infested, excellent quality and reasonable price. Application field: mainly used for vessel mooring, towage, fishing and mariculture etc. |

|||||||||

| 8-Strand and 12-Strand Polyester Mooring Rope | |||||||

|

Diameter (mm) |

Circumference (INCH) |

Linear densit(Ktex) | Deviation (%) |

Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 20 | 2-1/2 | 303 | ±5 | 60.6 | 62.3 | 6.36 | |

| 24 | 3 | 437 | ±5 | 87.4 | 89.6 | 9.14 | |

| 28 | 3-1/3 | 594 | ±5 | 118.8 | 120 | 12.24 | |

| 32 | 4 | 778 | ±5 | 155.6 | 154 | 15.71 | |

| 36 | 4-1/4 | 982 | ±5 | 196.4 | 190 | 19.39 | |

| 40 | 5 | 1215 | ±5 | 243 | 235 | 23.98 | |

| 44 | 5-1/2 | 1468 | ±5 | 293.6 | 279 | 28.47 | |

| 48 | 6 | 1750 | ±5 | 350 | 329 | 33.57 | |

| 52 | 6-1/2 | 2050 | ±5 | 410 | 384 | 39.18 | |

| 56 | 7 | 2380 | ±5 | 476 | 439 | 44.80 | |

| 60 | 7-1/2 | 2730 | ±5 | 546 | 489 | 49.90 | |

| 64 | 8 | 3110 | ±5 | 622 | 568 | 57.96 | |

| 72 | 9 | 3930 | ±5 | 786 | 707 | 72.14 | |

| 80 | 10 | 4850 | ±5 | 970 | 867 | 88.47 | |

| 88 | 11 | 5870 | ±5 | 1174 | 1040 | 106.12 | |

| 96 | 12 | 6990 | ±5 | 1398 | 1230 | 125.51 | |

| 104 | 13 | 8200 | ±5 | 1640 | 1420 | 144.90 | |

| 112 | 14 | 9500 | ±5 | 1900 | 1620 | 165.31 | |

| 120 | 15 | 10900 | ±5 | 2180 | 1856 | 189.39 | |

| 128 | 16 | 12400 | ±5 | 2480 | 2130 | 217.35 | |

| 136 | 17 | 14000 | ±5 | 2800 | 2390 | 243.88 | |

| 140 | 17-1/2 | 15649 | ±5 | 3129.8 | 2523 | 257.45 | |

| Product: made with high grade multifilament polyester. Wear resistance ability rank only second to Chinion, but far higher than other fibers. With stable chemical properties, high acid resistant ability, good anti-stretch capacity, good stiffness, aging resistant, UV-resistant, good heat-resistant capacity, anti-fungal, nonabsorbent, hard to be deformed. Soft and smooth, high strength, long lifetime. Application filed: Mainly used in vessel mooring, ocean transportation, port operation, military industry and mining pulling, etc. |

|||||||

| 8-Strand and 12-Strand Double Fiber Braided Mooring Rope Of Polyester and Polyolefin | |||||||

|

Diameter (mm) | Circumference Cir (INCH) |

Linear densit(Ktex) | Deviation (%) |

Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 44 | 5-1\2 | 939 | ±5 | 188 | 277 | 28.25 | |

| 48 | 6 | 1110 | ±5 | 222 | 328 | 33.45 | |

| 52 | 4-1\2 | 1320 | ±5 | 264 | 382 | 38.96 | |

| 56 | 7 | 1520 | ±5 | 304 | 440 | 44.88 | |

| 60 | 7-1\2 | 1750 | ±5 | 350 | 502 | 51.2 | |

| 64 | 8 | 1990 | ±5 | 398 | 568 | 57.94 | |

| 72 | 9 | 2520 | ±5 | 504 | 710 | 72.42 | |

| 80 | 10 | 3110 | ±5 | 622 | 867 | 88.43 | |

| 88 | 11 | 3750 | ±5 | 750 | 1040 | 106.08 | |

| 96 | 12 | 4470 | ±5 | 894 | 1230 | 125.46 | |

| 104 | 13 | 5260 | ±5 | 1052 | 1430 | 145.86 | |

| 112 | 14 | 6050 | ±5 | 1210 | 1660 | 169.32 | |

| 120 | 15 | 6980 | ±5 | 1396 | 1890 | 192.78 | |

| 128 | 16 | 7950 | ±5 | 1590 | 2130 | 217.26 | |

| 136 | 17 | 8950 | ±5 | 1790 | 2390 | 243.78 | |

| 140 | 17-1\2 | 9525 | ±5 | 1905 | 2530 | 258.16 | |

| Product: It is made of the mixture of polyester and polyolefin fiber with special producing technology. The rope outside layer is covered with polyester fiber, the rope yarn should make up at least 40% of the total weight(to improve the wear-resistant capacity), inside is made up of 100% high strength polyolefin fiber. Advantages: high strength, light density, can float on the water, corrosion-resistant, seawater resistant, soft, nonabsorbent, UV resistant, good wear resistantl capacity and long lifetime, etc. Application field: shipbuilding, ocean transportation, national defence scientific research, port operation, anchoring and towage, etc. | |||||||

| 3-Strand Multifilament Polyester (Terylene) Rope | |||||||

|

Diameter (mm) |

Circumference Cir (INCH) |

Linear densit(Ktex) | Deviation

(%) |

Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 4 | 1\2 | 11.8 | ±10 | 2.36 | 2.9 | 0.3 | |

| 6 | 3\4 | 27 | ±10 | 5.4 | 5.54 | 0.57 | |

| 8 | 1 | 48 | ±10 | 9.6 | 10 | 1.02 | |

| 10 | 1-1\4 | 76 | ±8 | 15.2 | 15.6 | 1.59 | |

| 12 | 1-1\2 | 110 | ±8 | 22 | 22.3 | 2.28 | |

| 14 | 1-3\4 | 148 | ±8 | 29.6 | 31.2 | 3.18 | |

| 16 | 2 | 195 | ±5 | 39 | 39.8 | 4.06 | |

| 18 | 2-1\4 | 245 | ±5 | 49 | 49.8 | 5.08 | |

| 20 | 2-1\2 | 303 | ±5 | 60.6 | 62.3 | 6.36 | |

| 22 | 2-3\4 | 367 | ±5 | 73.4 | 74.7 | 7.62 | |

| 24 | 3 | 437 | ±5 | 87.4 | 89.6 | 9.14 | |

| 26 | 3-1\4 | 512 | ±5 | 102.4 | 105 | 10.71 | |

| 28 | 3-1\2 | 594 | ±5 | 118.8 | 120 | 12.24 | |

| 30 | 3-3\4 | 682 | ±5 | 136.4 | 134 | 13.67 | |

| 32 | 4 | 778 | ±5 | 155.6 | 154 | 15.71 | |

| 36 | 4-1\2 | 982 | ±5 | 196.4 | 190 | 19.39 | |

| 40 | 5 | 1215 | ±5 | 243 | 235 | 23.98 | |

| 44 | 5-1\2 | 1468 | ±5 | 293.6 | 279 | 28.47 | |

| 48 | 6 | 1750 | ±5 | 350 | 329 | 33.57 | |

| 52 | 6-1\2 | 2050 | ±5 | 410 | 384 | 39.18 | |

| 56 | 7 | 2380 | ±5 | 476 | 439 | 44.8 | |

| 60 | 7-1\2 | 2730 | ±5 | 546 | 489 | 49.9 | |

| Product: it is made of high grade multifilament polyester. Abrasive resistance ability rank only second to Chinlon, but far higher than other fibers. With stable chemical properties, high acid resistant ability, good anti-stretch capacity, good stiffness, aging resistant, high strength, reasonablel price, high performance cost ratio. Multifilament polypropylene yarn is carbon chain polymer compounds, with High stability of acid, alkali and antioxidant, is of high chemical resistance capacity, UV-resistant, good heat-resistant capacity, anti-fungal, nonabsorbent, hard to be deformed. Soft and smooth, high strength, long lifetime. Application field: mooring of the vessel, ocean transportation, port operation, military industry and mining pulling. | |||||||

| 3-Strand Polyamide (Nylon) Mooring Rope | |||||||

|

Diameter (mm) |

Circumference (INCH) |

Linear density (Ktex) | Deviation (%) |

Theoretical weight (kg/200M) |

Min.Breaking load | |

| (KN) | (Ton) | ||||||

| 4 | 1/2 | 10.5 | ±10 | 2.1 | 3.15 | 0.32 | |

| 6 | 3/4 | 22.5 | ±10 | 4.5 | 7.35 | 0.75 | |

| 8 | 1 | 40 | ±10 | 8 | 13.2 | 1.35 | |

| 10 | 1-1/4 | 62 | ±8 | 12.4 | 20.4 | 2.08 | |

| 12 | 1-1/2 | 89 | ±8 | 17.8 | 29.4 | 3 | |

| 14 | 1-3/4 | 122 | ±8 | 24.4 | 40.2 | 4.1 | |

| 16 | 2 | 158 | ±5 | 31.6 | 52 | 5.31 | |

| 18 | 2-1/4 | 200 | ±5 | 40 | 65.7 | 6.7 | |

| 20 | 2-1/2 | 245 | ±5 | 49 | 81.4 | 8.31 | |

| 22 | 2-3/4 | 300 | ±5 | 60 | 98 | 10 | |

| 24 | 3 | 355 | ±5 | 71 | 118 | 12.04 | |

| 26 | 3-1/4 | 420 | ±5 | 84 | 137 | 13.98 | |

| 28 | 3-1/2 | 485 | ±5 | 97 | 155 | 15.82 | |

| 30 | 3-3/4 | 555 | ±5 | 111 | 174 | 17.76 | |

| 32 | 4 | 630 | ±5 | 126 | 196 | 20 | |

| 36 | 4-1/2 | 800 | ±5 | 160 | 244 | 24.9 | |

| 40 | 5 | 990 | ±5 | 198 | 294 | 30 | |

| 44 | 5-1/2 | 1200 | ±5 | 240 | 351 | 35.82 | |

| 48 | 6 | 1420 | ±5 | 284 | 412 | 42.04 | |

| 52 | 6-1/2 | 1660 | ±5 | 332 | 479 | 48.88 | |

| 56 | 7 | 1930 | ±5 | 386 | 549 | 56.02 | |

| 60 | 7-1/2 | 2210 | ±5 | 442 | 626 | 63.88 | |

| Product: Polyamide commodity called Chinlon, also called Nylon. Polyamide mooring rope is mainly made by Nylon #66. Polyamide multifilament density is 1.12-1.14g/cm3, Polyamide mooring rope with high strength, good wear-resisting capacity, high alkali resistance performance, high resilience foam, when 3% elongation, spring back rate is 100%. Application field: Widely used in large ships, warships, towing, oil exploration, fisheries, mining, etc. |

|||||||

Mooring ropes are commonly used in maritime and marine environments. They play a crucial role in securing and stabilizing ships, boats, and other floating vessels to docks, piers, or other structures. Mooring ropes are essential for preventing the drifting or uncontrolled movement of vessels, especially in ports, harbors, and anchorages. They are also utilized in offshore oil and gas platforms to anchor and stabilize the structures in open sea conditions. Additionally, mooring ropes find applications in various marine activities such as towing, salvage operations, and offshore mooring systems.

Enhancing Marine Safety and Stability: Unleashing the Power of Mooring Ropes

In the vast maritime industry, ensuring the safety and stability of marine vessels is of utmost importance. A critical component in achieving this is the reliable and robust mooring rope. At Juli slings, we specialize in manufacturing and supplying a wide range of mooring ropes, including mooring hawsers, ship mooring ropes, polyester mooring ropes, floating mooring lines, mooring wire ropes, nylon mooring lines, berthing ropes, and marine mooring ropes.

Mooring Ropes: Ensure ship stability

Mooring ropes are instrumental in securing marine vessels, providing stability, and mitigating risks associated with wind, waves, currents, and tides. These ropes are designed to withstand immense forces and ensure vessels remain in position during berthing or anchoring. Mooring ropes serve as a vital link between the vessel and the dock or other mooring points, preventing drifting and potential collisions.

Diverse Range of Mooring Ropes

At Juli slings, we offer an extensive selection of mooring ropes tailored to various marine applications. Let's explore some of the specific types of mooring ropes we provide:

Mooring Hawser: Mooring hawsers are heavy-duty ropes designed to handle substantial loads and provide exceptional strength and reliability in mooring operations. These ropes are often made from high-quality synthetic fibers or traditional natural fibers, ensuring durability and longevity in marine environments.

Ship Mooring Rope: Ship mooring ropes are specifically crafted to meet the unique requirements of different types of vessels. They are available in various materials, including polyester, nylon, and polypropylene, with different diameters and constructions to accommodate different vessel sizes and mooring conditions.

Polyester Mooring Rope: Polyester mooring ropes offer excellent strength, abrasion resistance, and durability. These ropes are commonly used in marine applications due to their ability to withstand harsh weather conditions and maintain their performance over time.

Floating Mooring Line: Floating mooring lines are designed to have buoyancy, allowing them to stay on the water surface. This feature makes them ideal for applications where visibility and ease of handling are crucial, such as offshore operations or mooring in areas with strong currents.

Mooring Wire Rope: Mooring wire ropes are constructed using high-strength steel wires, providing exceptional tensile strength and resistance to external forces. These ropes are often used in heavy-duty applications and where additional toughness and durability are required.

Nylon Mooring Line: Nylon mooring lines are known for their excellent shock absorption capabilities and high strength-to-weight ratio. These ropes are commonly used in applications where flexibility and elasticity are desired to handle dynamic loads and sudden impacts.

Berthing Rope: Berthing ropes are designed to facilitate the safe berthing of vessels, ensuring smooth docking and minimizing the risk of damage. These ropes are typically constructed from robust materials and engineered to withstand the forces experienced during berthing.

Marine Mooring Rope: Marine mooring ropes encompass a broad category of ropes specifically designed for various marine applications. They are versatile, reliable, and tailored to meet the specific requirements of different vessels and mooring conditions.

Choose Juli slings for Exceptional Mooring Ropes

Partnering with a reputable mooring rope manufacturer and supplier like Juli slings ensures that you have access to superior quality ropes that meet the demanding needs of the maritime industry. Here's why we stand out as a trusted provider:

Quality and Durability: We prioritize uncompromising quality in every aspect of our mooring rope manufacturing process. Our ropes are meticulously crafted from premium materials using advanced techniques to ensure exceptional strength, durability, and resistance to environmental factors.

Customization Options: We understand that each marine operation has unique requirements. That's why we offer customization options, allowing you to select the right material, diameter, length, and construction for your specific needs. Our team of experts can assist you in choosing the optimal mooring rope solution for your vessel and mooring conditions.

Wide Range of Options: Our diverse product range encompasses various types of mooring ropes to cater to different vessel types, sizes, and operational needs. Whether you require ropes for small pleasure crafts or large commercial vessels, we have the expertise and selection to meet your requirements.

Expert Guidance and Support: Our knowledgeable team is committed to providing expert guidance and support throughout the selection process. We understand the challenges of marine operations and can assist you in choosing the most suitable mooring rope solution. We are here to address any inquiries, offer technical assistance, and ensure you make informed decisions.

Timely Delivery and Competitive Pricing: We value your time and strive to provide prompt delivery of our mooring ropes. Our streamlined manufacturing and supply chain processes enable us to meet your deadlines efficiently. Additionally, our competitive pricing ensures that you receive excellent value for your investment without compromising on quality.

Package

JULI standard export package:Customized packaging according to customer needs

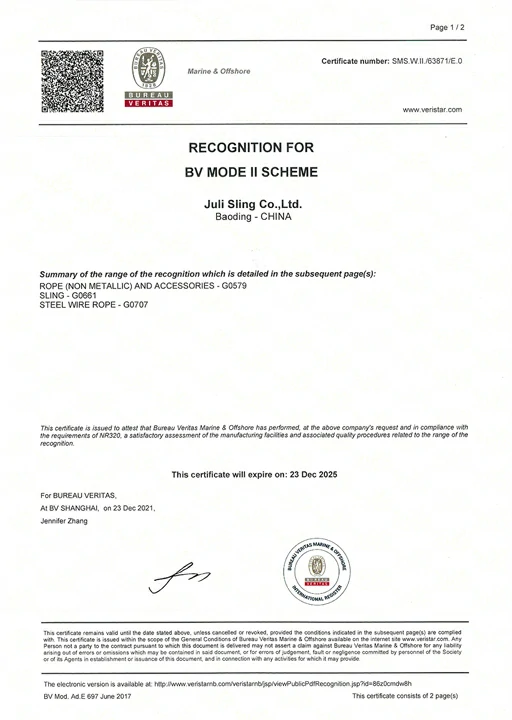

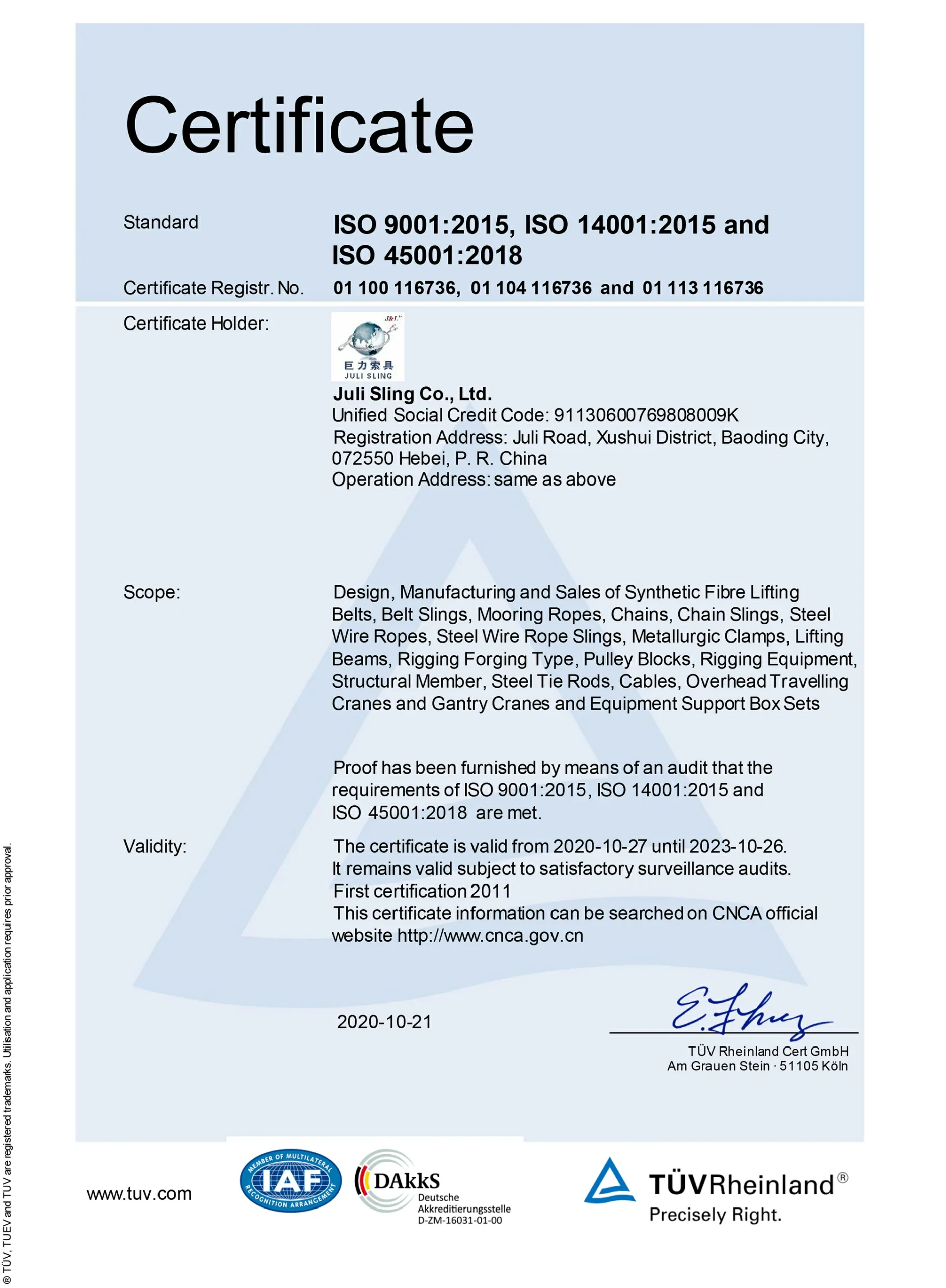

Certifications

DNV▪GL ISO CNAS

Production Process

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, Super high tensile strength polyethylene, aramid fibre and synthetic fibre. Diameter scope: Ф6mm ~ Ф140mm are available.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.