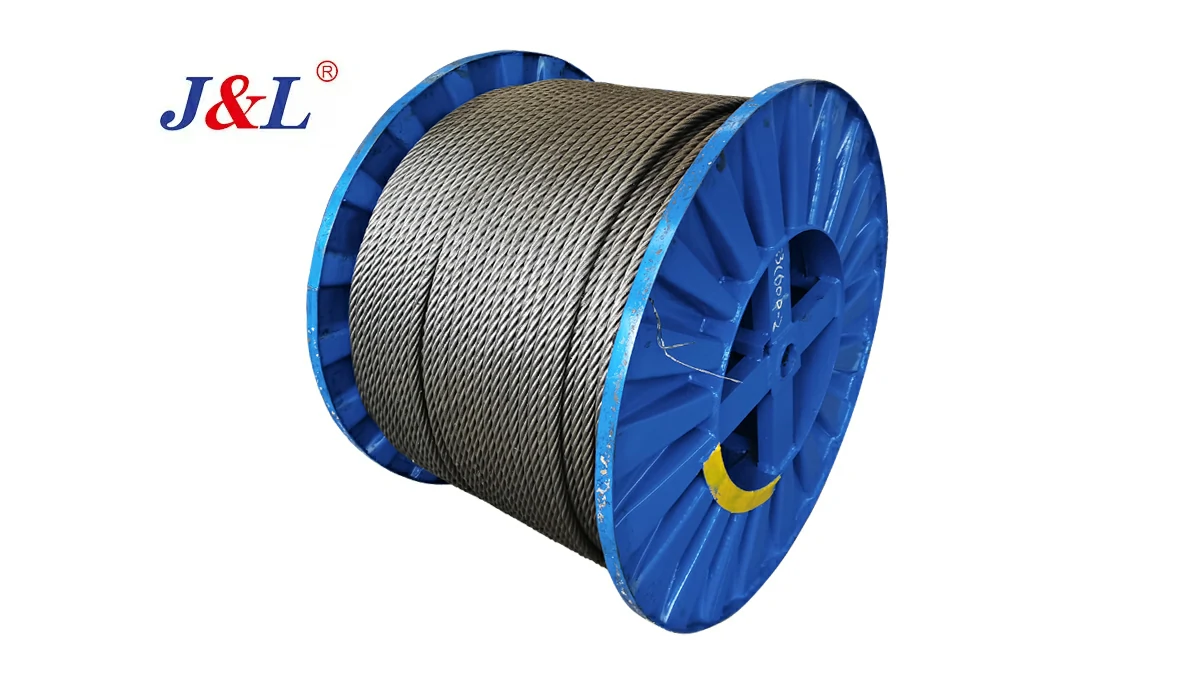

6×61N Single-layer Rope

6×61N Single-Layer Rope – High-Performance Wire Rope for Lifting & Towing

The 6×61N Single-Layer Rope is engineered for demanding industrial applications, combining outstanding strength, flexibility, and durability. With six strands, each made of 61 wires, this rope is designed to handle heavy loads while maintaining smooth operation. Its construction ensures long-lasting performance, making it an excellent choice for lifting, towing, and rigging in sectors such as construction, mining, offshore, and marine operations. For enhanced rigging systems, this rope pairs seamlessly with professional steel cable slings and rope sling solutions.

Core Construction Options

The 6×61N rope is available with two core types to suit specific operational needs:

-

Fiber Core (FC): Provides superior flexibility and shock absorption, ideal for operations requiring frequent bending, such as cranes with moving parts or winching systems.

-

Independent Wire Rope Core (IWRC): Offers maximum strength and resistance to crushing, suitable for heavy-duty lifting and high-tension tasks in harsh environments.

These options allow customization to meet the exact requirements of lifting, towing, or rigging projects, recommended by experienced steel wire rope suppliers.

High Strength and Flexibility

Constructed for heavy-duty applications, the 6×61N Single-Layer Rope provides excellent load-bearing capacity while remaining flexible enough to pass through pulleys, hoists, and other rigging equipment. The combination of high tensile strength and bendable design ensures reliability under extreme stress, giving operators confidence in both performance and safety.

Durability and Corrosion Resistance

The rope is available in galvanized or smooth finishes, providing protection against rust, abrasion, and environmental wear. This makes it suitable for outdoor, offshore, and marine applications, ensuring long service life and reduced maintenance costs. Its durability makes it an ideal choice for continuous operation in challenging conditions.

Versatile Industrial Applications

The 6×61N Single-Layer Rope is engineered for multi-industry use, including:

-

Heavy-Duty Lifting: Cranes, hoists, and winches for construction and mining operations.

-

Towing and Salvage: Capable of handling industrial vehicles, ships, and heavy machinery.

-

Construction and Mining: Reliable for lifting and rigging large equipment and materials safely.

-

Marine and Offshore: IWRC core enhances durability for offshore oil rigs and marine environments.

It also works efficiently with modern lifting systems and integrated rigging setups, especially when used alongside lifting sling solutions for additional safety and versatility.

Advantages

-

Enhanced Safety: High tensile strength reduces risk of rope failure in critical applications.

-

Long Service Life: Corrosion-resistant coatings and sturdy construction extend usability.

-

Customizable Options: Core types, diameters, and lengths can be tailored for your needs.

-

Smooth Operation: Flexible design reduces friction for efficient handling.

-

Reliable Performance: Ensures consistent function in dynamic and high-stress applications.

| Nominal diameter (mm) | Reference weight (kg/100m) | Rope Grade | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | ||||||||

| Minimum Breaking strength (kN) | ||||||||||||

| Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | |

| 80 | 2430 | 2780 | 3200 | 3480 | 3400 | 3700 | 3600 | 3920 | 3810 | 4140 | 3990 | 4340 |

| 82 | 2560 | 2920 | 3360 | 3650 | 3570 | 3890 | 3780 | 4120 | 4000 | 4350 | 4190 | 4560 |

| 84 | 2680 | 3070 | 3520 | 3830 | 3750 | 4080 | 3970 | 4320 | 4200 | 4570 | 4400 | 4790 |

| 86 | 2810 | 3220 | 3690 | 4020 | 3930 | 4270 | 4160 | 4530 | 4400 | 4790 | 4610 | 5020 |

| 88 | 2940 | 3370 | 3870 | 4210 | 4110 | 4480 | 4360 | 4740 | 4610 | 5010 | 4830 | 5250 |

| 90 | 3080 | 3520 | 4040 | 4400 | 4300 | 4670 | 4560 | 4960 | 4820 | 5240 | 5050 | 5490 |

| 92 | 3220 | 3680 | 4230 | 4600 | 4490 | 4890 | 4760 | 5180 | 5030 | 5480 | 5280 | 5740 |

| 94 | 3360 | 3840 | 4410 | 4800 | 4690 | 5110 | 4970 | 5410 | 5250 | 5720 | 5510 | 5990 |

| 96 | 3500 | 4010 | 4600 | 5010 | 4890 | 5330 | 5190 | 5640 | 5480 | 5960 | 5740 | 6250 |

| 98 | 3650 | 4180 | 4790 | 5220 | 5100 | 5550 | 5410 | 5880 | 5710 | 6210 | 5990 | 6510 |

| 100 | 3800 | 4350 | 4990 | 5430 | 5310 | 5780 | 5630 | 6120 | 5950 | 6470 | 6230 | 6780 |

| 104 | 4110 | 4700 | 5400 | 5880 | 5740 | 6250 | 6090 | 6620 | 6430 | 7000 | 6740 | 7330 |

| 108 | 4430 | 5070 | 5820 | 6340 | 6190 | 6740 | 6570 | 7140 | 6940 | 7550 | 7270 | 7910 |

| 112 | 4770 | 5460 | 6260 | 6810 | 6660 | 7250 | 7060 | 7680 | 7460 | 8120 | 7820 | 8510 |

| 116 | 5110 | 5850 | 6720 | 7310 | 7150 | 7780 | 7570 | 8240 | 8000 | 8710 | 8390 | 9130 |

| 120 | 5470 | 6260 | 7190 | 7820 | 7650 | 8380 | 8110 | 8920 | 8560 | 9350 | 8980 | 9770 |

| 124 | — | 6690 | — | 8350 | — | 8820 | — | 9420 | — | 9950 | — | — |

| 128 | — | 7130 | — | 8900 | — | 9470 | — | 10000 | — | 10060 | — | — |

| 132 | — | 7580 | — | 9470 | — | 10100 | — | 10700 | — | 11270 | — | — |

| 136 | — | 8050 | — | 10000 | — | 10700 | — | 11300 | — | 11970 | — | — |

| 140 | — | 8530 | — | 10600 | — | 11300 | — | 12000 | — | 12680 | — | — |

| 144 | — | 9020 | — | 11300 | — | 12000 | — | 12700 | — | 13420 | — | — |

| 148 | — | 9530 | — | 11900 | — | 12700 | — | 13400 | — | 14170 | — | — |

| 152 | — | 10100 | — | 12600 | — | 13300 | — | 14100 | — | 14950 | — | — |

| 156 | — | 10600 | — | 13200 | — | 14100 | — | 14900 | — | 15750 | — | — |

Why Choose Juli?

Juli provides industrial-grade lifting solutions with proven reliability. Our range includes webbing slings, round slings, mooring ropes, ratchet straps, steel wire ropes, and full rigging equipment. We combine quality materials, precise construction, and customization options to meet the most demanding lifting and towing requirements.

By choosing Juli, you gain access to professional lifting products that enhance safety, operational efficiency, and performance across all industrial applications.

.png)

.png)