8×7 Single-layer Rope

8×7 Single-layer Rope – High-Strength Wire Rope for Industrial Applications

The 8×7 Single-layer Rope is a strong, versatile, and durable wire rope engineered to meet the demanding requirements of industrial and commercial operations. With an optimized strand structure, this rope delivers outstanding tensile strength, excellent flexibility, and long service life. Its robust design enables stable performance in harsh environments where consistent reliability and resistance to abrasion are essential.

Suitable for lifting, towing, binding, rigging, and cargo-securing applications, the 8×7 Single-layer Rope provides dependable load-bearing capacity across dynamic and static conditions. It is available with multiple core options—including Fiber Core (FC)—allowing users to select the appropriate configuration based on specific operating environments. For applications requiring enhanced corrosion resistance or added safety, this rope is also compatible with solutions from industry-leading galvanized steel wire rope manufacturers.

Engineered for heavy-duty use, this single-layer construction rope is ideal for marine, transportation, construction, forestry, and industrial sectors where durability and long-term stability matter.

Specifications

-

Product Type: 8×7 Single-layer Rope

-

Construction:

-

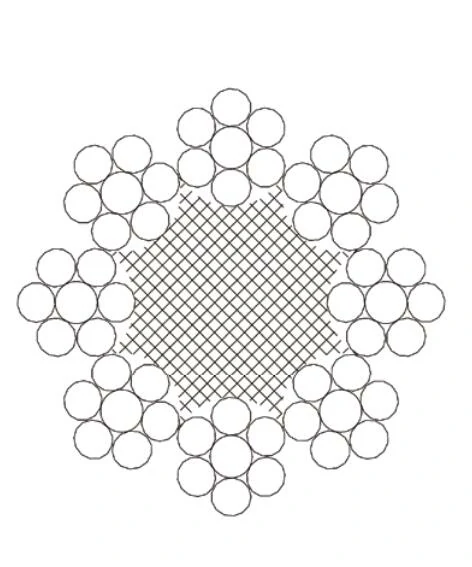

8×7SFC-FC (8 strands × 7 wires, Fiber Core)

-

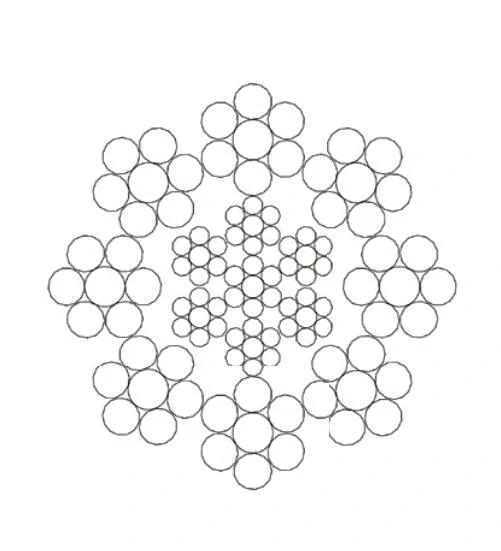

8×7WFC-FC (8 strands × 7 wires, Wire Strand Core + Fiber Core)

-

-

Core Options: Fiber Core (FC)

-

Rope Diameter: Fully customizable to operational needs

-

Surface Finish: Galvanized or Smooth

-

Tensile Strength: High load-bearing capacity suitable for heavy-duty use

-

Compliance: Conforms to GB/T, EN, ISO, and international standards

-

Origin: Hebei, China

-

Brand: J&L

Advantages

1. Superior Flexibility

The 8×7 Single-layer Rope is designed with multi-wire strands that deliver outstanding flexibility. This allows the rope to bend, twist, and move easily during operation—an essential feature for lifting, towing, and applications involving continuous dynamic loads. Its flexible structure also simplifies handling and installation on-site.

2. High Tensile Strength

Thanks to its 8×7 construction, the rope provides remarkable tensile strength and fatigue resistance. Each strand contributes to evenly distributing the load across the rope, ensuring reliable performance under high tension. This makes it suitable for heavy lifting, transport operations, and equipment requiring stable, high-strength wire ropes.

3. Corrosion and Weather Resistance

Available in galvanized and smooth finishes, this rope offers excellent protection against rust, corrosion, and environmental wear. Its ability to withstand moisture, chemicals, and harsh weather conditions makes it ideal for marine and outdoor industrial use. When used together with steel cable slings or other lifting accessories, it forms a dependable rigging system for critical operations.

4. Customizable Core Options

The Fiber Core (FC) enhances the rope’s flexibility and shock absorption capabilities, making it suitable for dynamic operations. Meanwhile, the Wire Strand Core (WFC) provides higher strength and rigidity for applications that require added load control and minimal elongation. These options ensure that buyers can choose the ideal configuration tailored to their industrial needs.

Applications

The 8×7 Single-layer Rope is built for a wide range of industrial and marine applications, offering dependable performance in challenging environments.

• Ship Operations

Widely used in ship rigging, docking, towing, and mooring systems, the rope withstands high loads and continuous stress. Its corrosion-resistant finish ensures stable performance even in saltwater and marine climates.

• Binding and Securing Loads

In construction, logistics, and manufacturing, the rope provides secure binding for large and heavy materials. Its ability to handle tension without stretching or breaking ensures stability during loading, transport, and storage.

• Transportation Industry

Ideal for towing, hoisting, and cargo handling. Its strong, flexible construction supports demanding operations, from lifting heavy equipment to securing loads during long-distance transportation.

• Timber Floating and Forestry

Due to its excellent resistance to moisture and abrasion, the rope is widely used to bind and secure logs during timber floating. Its durability ensures safe transport in aquatic environments and rough handling conditions.

| Nominal diameter (mm) | Reference weight (kg/100m) | Rope Grade | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | ||||||||

| Minimum Breaking strength (kN) | ||||||||||||

| Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | Fiber-core | Steel-core | |

| 10 | 32.7 | 39.1 | 45.7 | 56.4 | 48.6 | 60 | 51.5 | 63.5 | 54.4 | 67.1 | 57 | 70.4 |

| 11 | 39.6 | 47.3 | 55.3 | 68.2 | 58.8 | 72.5 | 62.3 | 76.9 | 65.8 | 81.2 | 69 | 85.1 |

| 12 | 47.1 | 56.3 | 65.8 | 81.2 | 70 | 86.3 | 74.2 | 91.5 | 78.4 | 96.7 | 82.1 | 101 |

| 13 | 55.3 | 66.1 | 77.2 | 95.3 | 82.1 | 101 | 87 | 107 | 92 | 113 | 96.4 | 119 |

| 14 | 64.1 | 76.6 | 89.5 | 110 | 95.3 | 118 | 101 | 125 | 107 | 132 | 112 | 138 |

| 16 | 83.7 | 100 | 117 | 144 | 124 | 153 | 132 | 163 | 139 | 172 | 146 | 180 |

| 18 | 106 | 127 | 148 | 183 | 157 | 194 | 167 | 206 | 176 | 218 | 185 | 228 |

| 20 | 131 | 156 | 183 | 225 | 194 | 240 | 206 | 254 | 218 | 269 | 228 | 281 |

| 22 | 158 | 189 | 221 | 273 | 235 | 290 | 249 | 308 | 263 | 325 | 276 | 341 |

| 24 | 188 | 225 | 263 | 325 | 280 | 345 | 297 | 366 | 313 | 387 | 329 | 405 |

| 26 | 221 | 264 | 309 | 381 | 329 | 405 | 348 | 430 | 368 | 454 | 386 | 476 |

| 28 | 256 | 307 | 358 | 442 | 381 | 470 | 404 | 498 | 427 | 526 | 447 | 552 |

| 30 | 294 | 352 | 411 | 507 | 437 | 540 | 464 | 572 | 490 | 604 | 513 | 633 |

| 32 | 335 | 400 | 468 | 577 | 498 | 614 | 527 | 651 | 557 | 687 | 584 | 721 |

| 34 | 378 | 452 | 528 | 652 | 562 | 693 | 595 | 735 | 629 | 776 | 659 | 813 |

| 36 | 424 | 507 | 592 | 730 | 630 | 777 | 668 | 824 | 705 | 870 | 739 | 912 |

| Note:Sum of minimum breaking load = minimum breaking load of rope *1.150. | ||||||||||||

Why Choose Juli?

Juli is a trusted global provider of high-performance wire ropes and lifting solutions. From construction sites and ports to offshore rigs and forestry operations, we supply products engineered to meet the toughest industrial challenges.

With decades of expertise and strict quality control, Juli delivers reliable wire rope slings, steel cable slings, and heavy-duty rigging products designed for maximum performance, durability, and safety. Whether you need ropes for lifting, towing, binding, or transport, Juli ensures exceptional quality supported by industry-leading engineering.