What are the advantages of nylon hoisting straps in various fields?

January 21, 2025

When it comes to lifting, securing, and transporting heavy loads, nylon hoisting straps have become a preferred solution across industries worldwide.

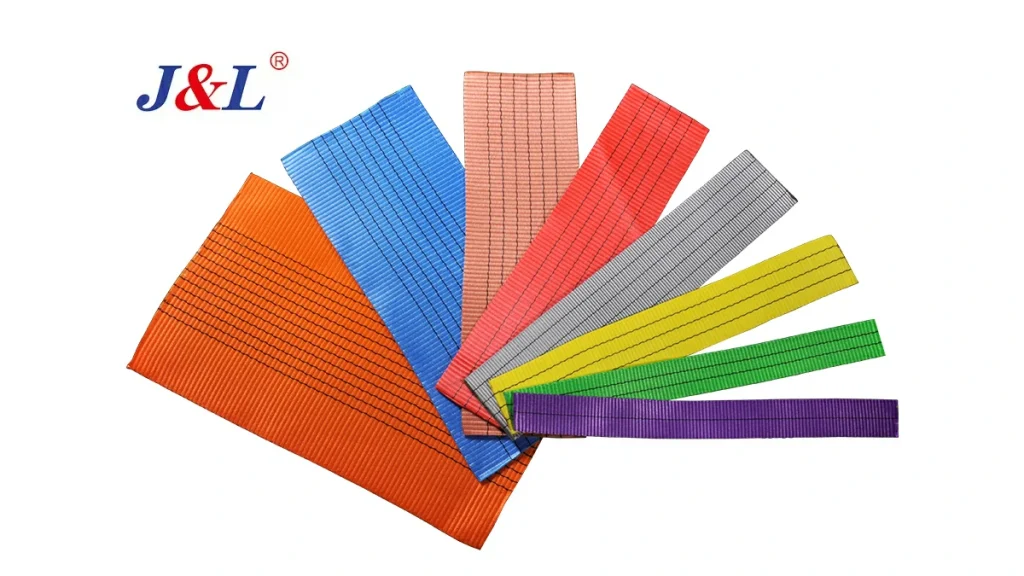

Juli Slings, as a trusted nylon lifting strap manufacturer, delivers high-quality lifting solutions that cater to a broad spectrum of applications. Whether it’s construction, logistics, marine, or automotive industries, nylon lifting slings provide a reliable, versatile, and cost-effective solution. Their unique combination of strength, lightweight design, and ease of use makes them the go-to option for professionals looking for an efficient way to move heavy loads.

Advantages of Nylon Material

Nylon, a synthetic polymer, is renowned for its exceptional performance in a wide range of applications. It is one of the most commonly used materials in manufacturing lifting slings, hoisting straps, and other industrial tools due to its unique properties. Here are the key advantages of nylon material:

1. High Tensile Strength

Nylon has a high tensile strength, meaning it can handle heavy loads without breaking or deforming. This makes it ideal for lifting and securing operations that involve significant weights. Nylon’s ability to withstand large amounts of force while maintaining its shape makes it a preferred choice for heavy-duty applications.

2. Durability and Resistance to Wear

Nylon is resistant to abrasion and wear, meaning it can last longer than many other materials, even under rough handling or harsh environments. It resists fraying and tearing, ensuring the longevity of products made from it, such as nylon hoisting straps and nylon lifting slings.

3. Lightweight

One of the most significant advantages of nylon is its light weight. Compared to metal or chain lifting systems, nylon hoisting straps are much easier to handle, reducing operator fatigue. This makes lifting operations quicker and more efficient.

4. Flexibility and Elasticity

Nylon has a natural elasticity that allows it to stretch and absorb energy without breaking. This characteristic is particularly useful in lifting and securing operations, as it helps absorb shocks and reduces the risk of sudden jerks that could damage the load or the equipment.

5. Chemical and UV Resistance

Nylon is resistant to a wide range of chemicals, oils, and solvents, making it ideal for use in harsh industrial environments. It also has good UV resistance, which makes it suitable for outdoor applications where exposure to sunlight is a factor.

6. Easy to Maintain

Nylon requires minimal maintenance compared to other materials like steel or metal chains. It is easy to clean, and its resistance to corrosion means it does not rust or degrade over time, even when exposed to moisture or outdoor conditions.

Why Choose Nylon Hoisting Straps?

- High Strength and Low Elongation

Nylon hoisting straps can handle loads up to 10 tons with elongation rates of less than 3% under maximum load conditions, ensuring tightness and stability during lifting operations. - Lightweight and Durable

Nylon lifting straps are up to 60% lighter than metal chains or cables, making them easier to handle and transport. They also resist wear, UV exposure, and temperatures ranging from -40°C to 100°C, ensuring durability in extreme environments. - Ease of Use and Versatility

Thanks to their adjustable length and flexibility, nylon lifting straps can be set up and removed in under 10 minutes, making them ideal for fast and efficient lifting in various industries.

Key Applications of Nylon Lifting Slings

Nylon hoisting straps are versatile and widely used in numerous fields, including:

- Lashing and Securing Loads: Ideal for securing heavy machinery, equipment, and cargo during transportation, ensuring loads remain stable and safe.

- Trailer Self-Rescue: When towing trailers, nylon lifting slings can be used for self-rescue operations, providing reliable and strong support to pull or lift the trailer out of challenging situations.

- Construction and Heavy Lifting: In construction, these straps are used for hoisting materials such as steel beams, concrete blocks, and other heavy construction components.

- Marine Industry: Nylon lifting straps are commonly used for lifting and securing boats, yachts, and other marine equipment during transport or storage.

- Automotive: From lifting car engines to securing vehicles during transit, nylon lifting straps provide the necessary support in automotive applications.

Safety Assurance and Certifications

At Juli Slings, we prioritize safety in all our products. Our nylon hoisting straps come with a safety factor of 2:1 or 3:1, ensuring that each strap can handle two or three times its rated load without failure. This provides an added layer of security for lifting operations.

Our products comply with international standards, including:

- EN 12195-2 (European Standard for Lifting and Lashing)

- AS/NZS438 (Australian/New Zealand Standard for Load Restraint)

- American Standards (for Load Lifting and Lashing)

Additionally, our nylon hoisting straps and nylon lifting slings are certified with CE and GS marks, ensuring they meet stringent quality and safety requirements. This guarantees that our straps are reliable, durable, and safe for a wide range of industrial applications.

In summary, nylon hoisting straps offer significant advantages across various industries due to their strength, durability, and ease of use. Whether it’s securing loads during transportation, assisting with trailer self-rescue, or handling heavy lifting in construction, nylon lifting slings provide reliable and safe support. Their versatility also extends to the marine and automotive sectors, where they are used for lifting boats, securing vehicles, and more. The lightweight yet robust nature of nylon hoisting straps ensures they meet the demanding requirements of each field, making them an essential tool for a wide range of applications.

Customized Service for Unique Needs

Understanding that different industries have varying requirements, Juli Slings offers customized services. We provide tailored solutions to meet specific lifting and securing needs. Whether you need special protection measures, specific strap lengths, or custom fittings, we can supply nylon hoisting straps that are perfectly suited for your application.

Juli Slings: Your Trusted Nylon Lifting Slings Supplier

At Juli Slings, we are dedicated to providing high quality, customizable nylon lifting slings tailored to your specific needs. Whether you need nylon hoisting straps for a unique application or customized lengths for your operation, we are here to support your business with the best lifting solutions on the market.

Visit our Facebook page for more product details of nylon hoisting straps!