6×24 Single-layer Rope

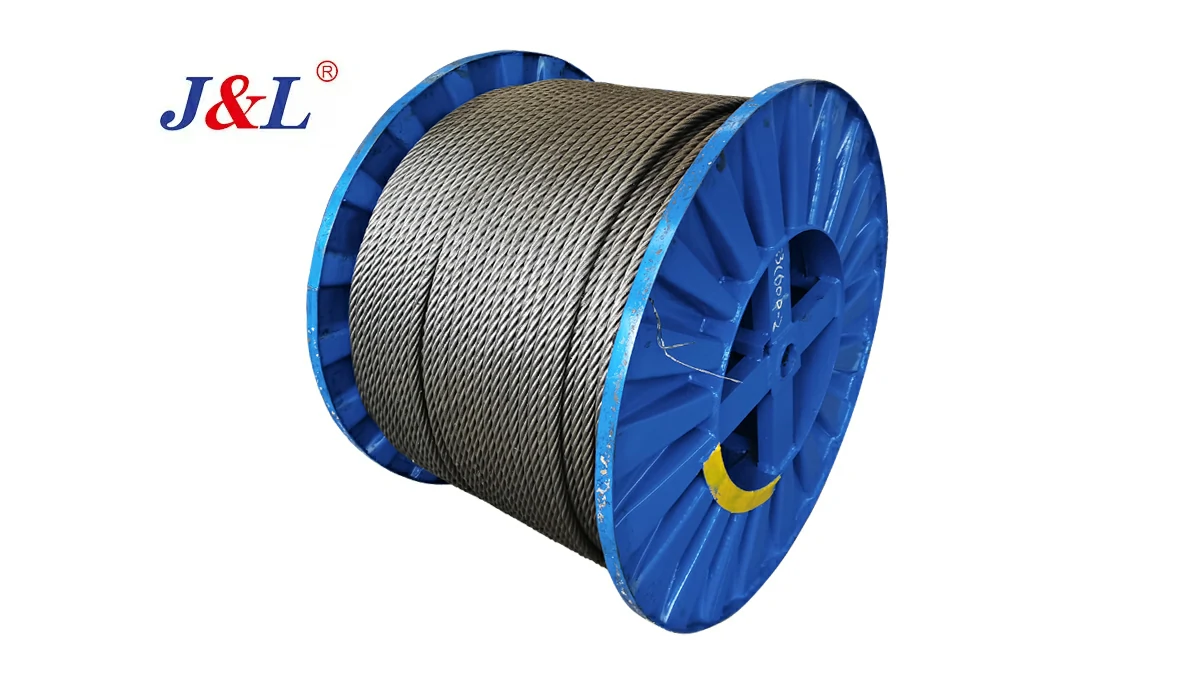

6×24 Single-layer Rope – Durable Wire Rope for Heavy-Duty Industrial Applications

The 6×24 Single-layer Rope is a highly durable and adaptable wire rope engineered to meet demanding performance requirements across multiple industrial sectors. Constructed with a balanced combination of tensile strength, flexibility, and long-term durability, this rope excels in operations that require consistent load-bearing capacity, resistance to tension fatigue, and stable performance in harsh working environments.

Ideal for ship operations, cargo binding, towing, and transportation tasks, the 6×24 Single-layer Rope is designed to withstand heavy loads while maintaining structural integrity. It is available with various core options, including Fiber Core (FC), ensuring versatility for marine, industrial, and logistics applications. For clients requiring complete lifting and rigging solutions, this rope integrates easily with products offered by leading steel wire rope suppliers.

Specifications

-

Product Type: 6×24 Single-layer Rope

-

Construction:

-

6×24SFC-FC: 6 strands × 24 wires, Fiber Core

-

6×24WFC-FC: 6 strands × 24 wires, Wire Strand Core + Fiber Core

-

-

Core Options: Fiber Core (FC)

-

Rope Diameter: Customizable for specific application requirements

-

Surface Finish: Galvanized or Smooth

-

Tensile Strength: High load-bearing capacity for heavy-duty use

-

Standards: GB/T, EN, ISO

-

Place of Origin: Hebei, China

-

Brand: J&L

Advantages

1. Superior Flexibility

The 6×24 structure incorporates multiple fine wires, resulting in excellent flexibility. This makes the rope easy to install, maneuver, and operate in dynamic environments where frequent bending and twisting occur. Its smooth handling contributes to greater operational efficiency.

2. High Tensile Strength

With its precisely engineered 6×24 construction, the rope distributes load evenly across all strands, maintaining stability under high tension. This ensures consistent performance during intensive lifting, pulling, and cargo-handling tasks.

3. Excellent Corrosion Resistance

Whether used in marine, industrial, or outdoor environments, the galvanized or smooth finish provides strong resistance against corrosion, moisture, and chemical exposure. This durability is crucial for long-term applications where environmental stress is unavoidable.

4. Customizable Core Choices

The Fiber Core (FC) enhances flexibility and shock absorption, while the Wire Strand Core (WFC) provides additional strength and minimal elongation. These options allow operators to select the ideal rope specification based on their exact working environment.

5. Exceptional Durability

Engineered for harsh working conditions, the 6×24 Single-layer Rope ensures long service life, reduces replacement frequency, and maximizes operational uptime—making it a cost-efficient choice for industrial users.

Applications

Engineered for versatility, the 6×24 Single-layer Rope is suitable for a wide range of heavy-duty tasks across marine, industrial, forestry, and transportation sectors.

• Ship Operations

Widely used in rigging, mooring, docking, and towing, the rope provides strong performance for demanding maritime tasks. Its corrosion resistance and high load capacity make it dependable for offshore and port environments.

• Binding and Securing Loads

The rope’s tensile strength makes it ideal for securing heavy cargo in construction, logistics, and shipping industries. It maintains stability under tension, preventing slippage or deformation.

• Transportation & Cargo Handling

In transportation, the rope excels in lifting, hoisting, towing, and securing loads in motion. Its flexibility and strength make it well-suited for cranes, winches, transport vehicles, and industrial handling equipment.

• Timber Floating & Forestry

The rope performs exceptionally well in moisture-rich environments, making it a preferred option for timber floating and log handling. Its structural durability ensures reliable performance even during extended aquatic operations.

• General Lifting & Rigging

For lifting, pulling, hoisting, and general rigging, the 6×24 Single-layer Rope delivers dependable strength and long-term safety. When combined with high-quality steel cable slings or textile sling solutions, it forms a complete and secure lifting system.

| Nominal diameter (mm) | Reference weight (kg/100m) | Rope Grade | ||

| 1570 | 1670 | 1770 | ||

| Minimum breaking load (kN) | ||||

| 14 | 64.9 | 89.5 | 95.3 | 101 |

| 15 | 74.5 | 103 | 109 | 116 |

| 16 | 84.7 | 117 | 124 | 132 |

| 18 | 107 | 148 | 157 | 167 |

| 20 | 132 | 183 | 194 | 206 |

| 22 | 160 | 221 | 235 | 249 |

| 24 | 191 | 263 | 280 | 297 |

| 26 | 224 | 309 | 329 | 348 |

| 28 | 260 | 358 | 381 | 404 |

| 30 | 298 | 411 | 437 | 464 |

| 32 | 339 | 468 | 498 | 527 |

| 34 | 383 | 528 | 562 | 595 |

| 36 | 429 | 592 | 630 | 668 |

| 38 | 478 | 660 | 702 | 744 |

| 40 | 530 | 731 | 778 | 824 |

| Note:sum of minimum breaking force = minimum breaking force of rope *1.150. | ||||

Why Choose Juli?

Juli is a trusted global manufacturer offering comprehensive lifting, rigging, and securing solutions for industrial users. From construction and marine applications to mining, forestry, and logistics, our products are engineered to deliver superior strength, durability, and performance. Whether you require advanced steel wire rope slings or textile lifting solutions like lifting sling systems, Juli provides safe, reliable, and efficient products for B2B customers worldwide.

Choose Juli for your lifting, towing, binding, and rigging needs. We ensure consistent quality backed by industry-leading engineering and strict international standards.