What are the key factors to consider when choosing Polyester Sling Webbing for heavy lifting?

February 8, 2025

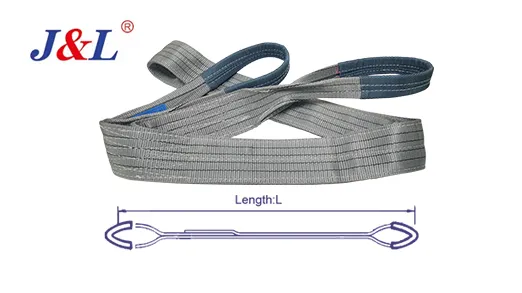

In industries where heavy lifting is an essential part of daily operations—such as construction, manufacturing, shipping, and logistics—selecting the right lifting equipment is critical. Among the various lifting solutions available, Polyester Webbing Slings have become a preferred choice due to their strength, flexibility, and lightweight nature. Unlike steel chains or wire ropes, polyester sling webbing minimizes damage to lifted loads while offering excellent durability and resistance to environmental factors.

However, not all polyester flat webbing slings are created equal. To ensure safe and efficient lifting, several key factors should be taken into account when selecting the right sling.

Polyester Sling Webbing Features

When choosing a polyester webbing sling, it’s important to understand its key features that make it a reliable lifting solution:

✅ High Strength-to-Weight Ratio – Offers excellent lifting capacity while being much lighter than steel alternatives.

✅ Low Stretch – Provides stability when lifting, ensuring precise load control.

✅ Soft and Flexible – Minimizes damage to delicate or painted surfaces.

✅ Corrosion & Chemical Resistance – Unlike metal chains, polyester does not rust or corrode in harsh environments.

✅ UV & Moisture Resistance – Ideal for both indoor and outdoor use.

✅ Easy to Store & Transport – Lightweight and flexible, making handling and storage simple.

✅ Multiple Configurations Available – Comes in different widths, layers, and end fittings to suit various lifting applications.

The Importance of Choosing the Right Polyester Webbing Slings

Selecting the correct polyester webbing sling is crucial for safety, efficiency, and cost-effectiveness in lifting operations. Using the wrong sling can lead to serious consequences, including equipment damage, workplace injuries, or even fatal accidents. Here’s why making the right choice matters:

✅ Ensures Safety – A properly selected polyester sling webbing prevents overloading, reducing the risk of sudden failures and accidents.

✅ Improves Efficiency – The right sling minimizes downtime and enhances operational workflow by handling loads effectively.

✅ Protects the Load – Unlike steel chains or wire ropes, polyester flat webbing slings are softer and do not damage delicate or painted surfaces.

✅ Extends Equipment Lifespan – Using a suitable sling prevents excessive wear and tear, reducing maintenance and replacement costs.

✅ Meets Compliance Requirements – Selecting slings that comply with safety regulations ensures that businesses adhere to industry standards and avoid legal liabilities.

By understanding the key factors in sling selection, companies can significantly improve lifting operations while maintaining the highest safety standards.

Key Factors to Consider When Choosing Polyester Sling Webbing

1. Load Capacity & Working Load Limit (WLL)

Every polyester sling webbing is rated with a Working Load Limit (WLL), indicating the maximum weight it can safely lift. Choosing a sling with the appropriate WLL for your application is crucial—exceeding this limit can result in failure, posing risks to both personnel and equipment.

2. Webbing Strength & Durability

The durability of a polyester flat webbing sling depends on the quality of the polyester fibers used. High-strength polyester provides excellent tensile strength, low stretch, and superior wear resistance. Additionally, reinforced stitching and multiple layers contribute to the sling’s overall longevity under heavy use.

3. Sling Width & Configuration

The width and number of layers in a polyester webbing sling impact its lifting capability. Wider slings distribute weight more evenly, reducing pressure points on both the load and the sling itself. Multi-layered designs enhance strength, making them ideal for handling heavier loads.

4. Resistance to Environmental Factors

Unlike steel lifting equipment, polyester sling webbing is resistant to moisture, mildew, and many chemicals. It also offers UV resistance, making it suitable for outdoor applications. For work environments with extreme temperatures, oils, or corrosive substances, selecting a sling with additional protective coatings ensures longevity and reliability.

5. Compliance with Safety Standards

A high-quality polyester webbing sling should comply with international safety standards, such as EN 1492-1 or ASME B30.9. Certified slings undergo rigorous testing to ensure they meet performance and safety requirements, reducing the risk of failure in lifting operations.

6. Proper Labeling & Identification

To enhance workplace safety, polyester sling webbing should have clear labels with essential information, including load limits, material specifications, and proper usage guidelines. Proper identification helps workers quickly verify the sling’s capabilities and prevents misuse.

About Juli

Juli is a leading manufacturer of polyester webbing slings, polyester flat webbing slings, and polyester sling webbing, providing top-tier lifting solutions for industries worldwide. Known for high-quality craftsmanship, durability, and compliance with international safety standards, Juli’s products ensure maximum performance and reliability in heavy-duty lifting applications.

For businesses looking for durable and efficient polyester sling webbing, Juli delivers trusted solutions designed to enhance safety and productivity in lifting operations.

Visit our Facebook page for more product details of polyester webbing slings!