How to Choose Different Types of Shackles?

May 14, 2025

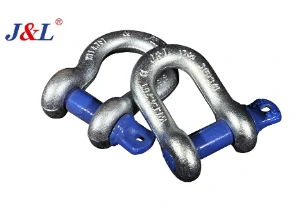

When planning to undertake lifting and rigging operations, the choice of the right shackles stands as the cornerstone of the safety and efficiency of the operation. A variety of shackles offering different applications such as bow shackles D-shackles, and big shackles and possessing remarkable characteristics are available for your selection. A comparison of these types of shackles, the way they look, etc., will help you decide which shackle is the best fit for your purposes.

Types of Shackles

1. Bow Shackles

The bow shackle has a broader, more gentle curve than other types and is designed to attach different loads at its ends. This makes them useful in applications that require very flexible connections. The shape of the bow shackle allows the force to be distributed across the body and pin, thereby resulting in less stress or damage to the material altogether.

Key Features:

Wide Opening: The wide jaw of the shackle enables the connection of more than one sling or hook to it.

High Load Capacity: Bow shackles can deal with loads from 0.5t to 150t.

Safety Factor: These kinds of shackles are commonly available in safety factors of the model, that could be 4:1, 6:1 or even 8:1.

When to Use:

This kind of shackle can be chosen when the application needs multiple or single points of attachment simultaneously or if the load is to be uniformly distributed. Most tasks in construction, shipping, and industrial fields are laborious.

2. D-Shackles

D shape of the shackle actually is the main reason that by survey looks like the letter “D”. Consequently, a less convoluted load will find ease in establishing more firm and direct contact with the shackle.

Key Features:

D-shackles come in a compact design that enables them to be inserted into smaller spaces, making them multi-functional and to be used in different applications.

High Strength: D-shackles are synonymous with high-strength and reliability as they are made from high-quality alloy steel.

Working Load Limit (WLL): Usually, D-shackles have a WLL that is determined by their size and the materials they are made of, which varies from 0.5t to 85t.

When to Use:

D-shackles are generally preferred in cases where a secure link is needed for lifting or rigging tasks having a direct load path. They are widely used not only in marine operations and making of building but also in connecting equipment.

3. Big Shackles

big shackles are the main item on the list of devices that are used for lifting heavy items and they can handle quite large loads. These shackles are normally employed in those industrial activities where their strength and reliability are the crucial prerequisites.

Key Features:

Big shackles can lift big weights, ranging from 200t to 2000t and so, allowing them to be the most suitable option for the demanding tasks.

Durability: The big shackles are manufactured using high-quality alloy steel that undergoes a very rigorous heat treatment. Also, they are designed to endure the hardest tasks.

When to Use:

Big shackles must be employed in very tough operations like construction, heavy machinery, or shipping. Without them, it would be impossible to lift heavy and big items.

Factors to Consider When Choosing Shackles

1. Load Capacity

Always check the working load limit (WLL) of the shackle. Ensure it exceeds the maximum load you plan to lift. Overloading can lead to failure and accidents.

2. Material

Shackles are typically made from carbon steel, alloy steel, or stainless steel. Choose the material based on the environment in which the shackle will be used. For example, stainless steel is ideal for corrosive environments, while alloy steel offers high strength for heavy-duty applications.

3. Safety Factor

The safety factor indicates how much weight a shackle can handle beyond its rated capacity. Common safety factors are 4:1, 6:1, and 8:1. Select a shackle with a safety factor that meets or exceeds your operational requirements.

4. Type of Connection

Consider how the shackle will be connected to other equipment. Bow shackles are great for multiple connections, while D-shackles are better for direct connections. Ensure the design fits your lifting setup.

5. Treatment and Coating

Look for shackles with protective coatings, such as galvanizing or painting, to enhance durability and resistance to corrosion. This is especially important for shackles used in outdoor or marine environments.

Conclusion

Choosing the right shackle, whether it’s a bow shackle, D-shaped shackle or large shackle, is crucial to ensuring safe and efficient lifting operations. By analyzing parameters such as load capacity, safety factor, connection type and more, you can find the shackle that best meets your specific needs.

In addition, if you are looking for the right shackle, please contact us!