Mastering Wire Rope Sling Capacity

June 4, 2025

The Unseen Strength: Why Accurate Sling Capacity is Non-Negotiable

Wire rope slings are industrial workhorses, but their safe use hinges on precise capacity calculations. Miscalculations aren’t minor errors; they’re critical oversights leading to equipment failure, injuries, and severe financial loss.

Prevent Catastrophes: Overloading can cause dropped loads, severe injuries, even fatalities. Accurate WLL knowledge is your first defense.

Ensure Compliance: Adhere to OSHA & ASME standards. Proper calculations are a legal and ethical mandate for workplace safety.

Maximize ROI: Prevent premature wear and equipment damage, extending sling lifespan and reducing operational downtime.

Decoding the Sling: Anatomy of Strength

Understanding a sling’s construction and configuration is crucial for selecting the right tool and assessing its capacity.

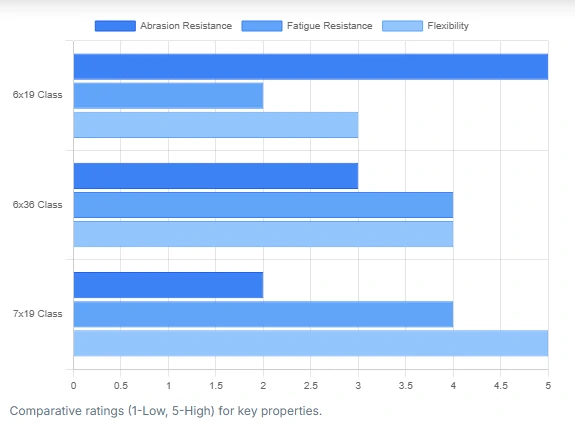

Wire Rope Constructions

Different arrangements of wires and strands (e.g., 6×19, 6×36, 7×19) dictate flexibility, abrasion resistance, and fatigue life. Choose based on application demands.

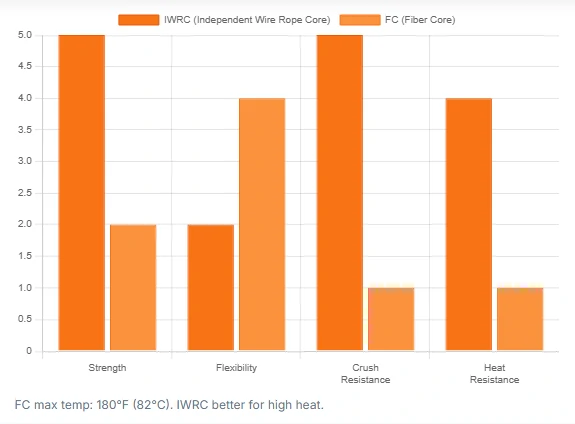

The Core Truth: FC vs. IWRC

The core supports the strands. Fiber Core (FC) offers flexibility, while Independent Wire Rope Core (IWRC) provides strength and crush resistance. IWRC adds ~7.5% to rope strength.

Hitch Configurations & Capacity Impact

How a sling is rigged drastically changes its lifting capacity. Know these common hitches:

Vertical Hitch Capacity: 100% WLL Direct pull, full rated capacity.

Choker Hitch Capacity: ~75% WLL* *If choke angle < 120°. Never choke on fittings.

Basket Hitch (Vertical Legs) Capacity: ~200% WLL Distributes load on two legs. Ensure balance.

Multi-Leg Bridle Capacity: Angle Dependent Angles greatly reduce capacity. Lower angle = higher stress.

The Calculation Core: Key Factors Influencing Capacity

Beyond the tag, several factors dynamically alter a sling’s true lifting power in the field.

MBL to WLL: The Safety Foundation

Minimum Breaking Load (MBL) is the rope’s ultimate strength. Working Load Limit (WLL) is the safe max load.

WLL = MBL / Safety Factor

Typically Safety Factor is 5:1 (general) or 10:1 (personnel).

Example: MBL 25,000 lbs, SF 5 ➔ WLL 5,000 lbs.

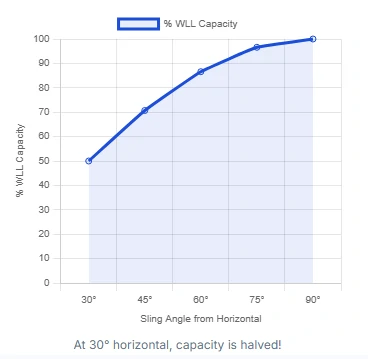

The Angle Factor: A Critical Tilt

Sling angle dramatically impacts tension. Smaller horizontal angles significantly reduce capacity.

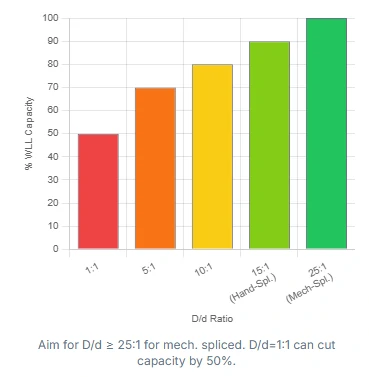

D/d Ratio: Bend Without Breaking

Diameter of Curvature (D) to rope diameter (d). Small D/d ratios reduce strength significantly.

The Calculation Pathway: Step-by-Step

Follow this systematic approach to determine safe wire rope sling capacity for your lift.

1.Find MBL(Manufacturer Spec)

2.Apply Safety Factor(WLL = MBL / SF)

3.Adjust for Sling Angle(Reduces capacity)

4.Account for Hitch Type(Choker, Basket, etc.)

5.Consider D/d Ratio(Impacts efficiency)

6.Safe Lift Capacity!(Consult expert if unsure)

Example: 1″ IWRC sling (MBL 100,000 lbs), SF 5, in a 2-leg bridle at 45° horizontal.

1. WLL (Vertical per leg) = 100,000 / 5 = 20,000 lbs.

2. Adjusted WLL per leg (45°) = 20,000 lbs * 0.707 = 14,140 lbs.

3. Total Adjusted WLL (2-leg bridle) = 14,140 lbs * 2 = 28,280 lbs. (Assuming balanced load & good D/d)

Safety First: Practices & Pitfalls

Accurate calculations are vital, but a strong safety culture and diligent practices are equally important.

Vigilant Inspections: Your First Line of Defense

A competent person must inspect slings daily before use, with periodic detailed inspections (yearly for normal service, monthly/quarterly for severe).

Key Defects to Spot & Remove Sling For:

❗Missing/illegible ID tag

❗Broken wires (e.g., >10 in one lay)

❗Kinking, crushing, bird-caging

❗Heat damage or severe corrosion

❗Worn/cracked/deformed end attachments

❗Diameter reduction > 5%

Always remove damaged slings from service immediately!

Common Mistakes to Avoid

Steer clear of these common errors to ensure safety and prolong sling life:

✗Incorrectly measuring rope diameter.

✗Improper installation of wire rope clips.

✗Ignoring D/d ratio & not protecting slings at sharp corners.

✗Using damaged slings –NEVER DO THIS!

✗Overlooking environmental factors (heat, corrosion).

✗Inadequate lubrication and improper storage.

Best practice: ✔ Regular training for all personnel.

Learn more: Steel Wire Rope;Wire Rope Sling;Mooring Rope;Lifting Sling.

If you have any questions,welcome to contact us!