The Ultimate Guide to Slings for Rigging: 4 Essential Types Explained for 2025

August 27, 2025

Abstract

The practice of lifting and moving heavy loads, fundamental to industries from construction to maritime logistics, depends profoundly on the integrity of its equipment. This examination focuses on the selection, application, and maintenance of slings for rigging, a subject where technical knowledge intersects with the ethical imperative of workplace safety. It provides a systematic analysis of the four primary categories of lifting slings: synthetic web, synthetic round, wire rope, and alloy chain. Each category is evaluated based on its material composition, mechanical properties, operational advantages, and inherent limitations. The discourse extends to the concepts of Working Load Limit (WLL), the physics of sling angles, and the non-negotiable protocols for inspection and retirement. By situating these technical specifications within a framework of human responsibility, this analysis argues that the proper use of slings for rigging is not merely a matter of regulatory compliance but a direct expression of a commitment to preserving human well-being in complex operational environments. The objective is to equip professionals with the nuanced understanding required to make informed, safe, and efficient decisions in all lifting operations.

Key Takeaways

- Always match the sling material to the load and environment.

- Never exceed the manufacturer’s stated Working Load Limit (WLL).

- Correctly calculating sling angles prevents catastrophic failures.

- Inspect all slings for rigging before each use without exception.

- Understand that UV radiation and chemicals degrade synthetic slings.

- Remove any damaged or questionable sling from service immediately.

- Proper storage is just as vital as proper use for sling longevity.

Table of Contents

- The Foundational Principles of Safe Rigging

- The Four Pillars: A Comparative Overview of Lifting Slings

- Type 1: The Synthetic Web Sling

- Type 2: The Synthetic Round Sling

- Type 3: The Wire Rope Sling

- Type 4: The Alloy Chain Sling

- Frequently Asked Questions (FAQ)

- A Concluding Thought on Responsibility

- References

The Foundational Principles of Safe Rigging

Before one can even begin to differentiate between the various types of slings for rigging, one must first grasp the context in which they operate. Rigging is not simply about connecting a hook to a load. It is a discipline, a blend of science and art that requires a deep appreciation for physics, material science, and situational awareness. At its heart, the act of rigging is an act of trust—trust in the equipment, trust in the plan, and trust in the rigger’s judgment. A failure in any of these areas does not lead to minor inconveniences; it can lead to catastrophic failure, resulting in immense financial loss and, more tragically, severe injury or loss of life.

The central figure in this narrative is the sling itself. Think of a sling as the temporary, flexible connection between the lifting machine (like a crane or hoist) and the load. Its job is to securely grip the object and bear its full weight, often under dynamic forces. The selection of the appropriate sling is therefore the rigger’s first and most consequential decision. This choice is not arbitrary, nor is it based on mere convenience. It is a calculated decision informed by a host of variables: the weight of the load, its shape and center of gravity, the sensitivity of its surface, the ambient temperature, and potential exposure to chemicals or other environmental hazards.

A concept that must become second nature to anyone involved in lifting is the Working Load Limit (WLL). The WLL, sometimes referred to as the rated capacity, is the maximum mass or force which a piece of lifting equipment is authorized to support in a particular service julislings.com. This value is not a recommendation; it is a strict limit determined by the manufacturer, incorporating a safety factor. For instance, a sling might have a design factor of 5:1, meaning its minimum breaking strength is five times its WLL. This built-in margin of safety accounts for unforeseen stresses, such as minor shock loading or slight wear, but it should never be intentionally violated. To overload a sling is to gamble with forces you cannot control, eroding the very foundation of safe practice.

Equally significant is the effect of the sling angle. When two or more sling legs are used in a bridle hitch, the angle at which they connect to the load dramatically affects the tension in each leg. Imagine you are holding a shopping bag with one hand, directly above it. Your arm feels the full weight. Now, imagine holding a bag in each hand, with your arms spread wide apart. The strain on your arms feels much greater than the combined weight of the bags. The same principle applies to slings. As the angle between the sling leg and the horizontal decreases, the tension on that leg increases exponentially. A rigger who fails to account for this geometric reality is unknowingly multiplying the forces on their equipment, potentially exceeding the WLL even if the load itself is well within the sling’s capacity. The American Society of Mechanical Engineers (ASME) provides detailed charts and formulas in its B30.9 Sling Safety standard, which should be a constant companion for any rigging professional (ASME, 2021).

The Four Pillars: A Comparative Overview of Lifting Slings

The world of rigging presents us with four principal families of slings, each with a distinct personality, a unique set of capabilities, and specific limitations. These are synthetic web slings, synthetic round slings, wire rope slings, and alloy chain slings. Choosing among them requires a thoughtful consideration of the task at hand. There is no single “best” type of sling; there is only the “right” sling for a specific lift. A rigger’s expertise is demonstrated not by a blind loyalty to one type but by the wisdom to select the optimal tool for the job.

Let us consider a brief comparison to frame our deeper exploration. Think of a web sling as a wide, soft belt, ideal for protecting delicate surfaces. A round sling is its cousin, a high-capacity, pliable loop that conforms perfectly to irregular shapes. A wire rope sling is the workhorse, a bundle of steel strands offering a rugged and abrasion-resistant solution. Finally, an alloy chain sling is the most durable and resilient of all, capable of withstanding high temperatures and harsh conditions that would destroy other types. Understanding these fundamental differences is the first step toward mastery in the selection of slings for rigging.

Sling Type Comparison

| Feature | Synthetic Web Sling | Synthetic Round Sling | Wire Rope Sling | Alloy Chain Sling |

|---|---|---|---|---|

| Material | Nylon or Polyester Webbing | Polyester Fibers (Core) & Cover | Steel Wires | Grade 80, 100, or 120 Alloy Steel |

| Flexibility | High; flat surface spreads load | Highest; conforms to any shape | Moderate; can kink | Low; flexible but not pliable |

| Strength-to-Weight | Good | Excellent | Very Good | Good |

| Abrasion Resistance | Low to Moderate | Low (Cover); High (Core) | Good | Excellent |

| Temperature Limit | Approx. 90°C (194°F) | Approx. 90°C (194°F) | Approx. 204°C (400°F) | Approx. 204°C (400°F) |

| Chemical Resistance | Varies (Nylon vs. Polyester) | Good (Polyester) | Poor (Susceptible to corrosion) | Good (Can be coated) |

| Cost | Low | Low to Moderate | Moderate | High |

| Primary Advantage | Protects finished surfaces | Conforms to irregular loads | General purpose, durable | Most durable, high-temp use |

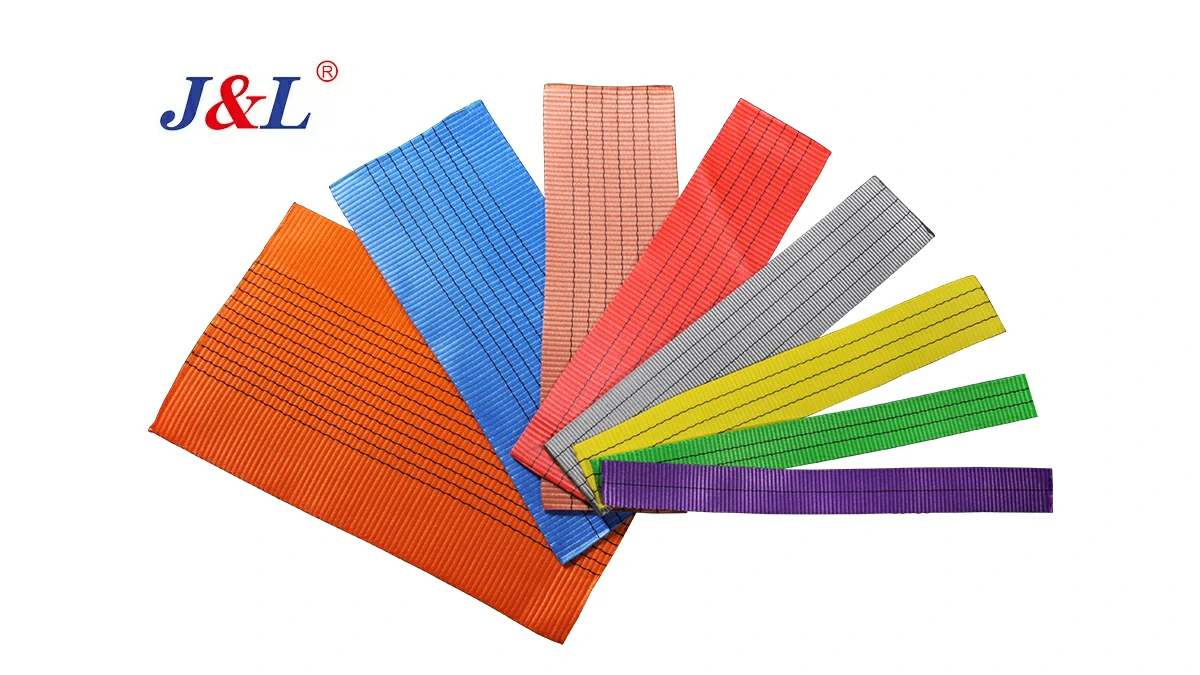

Type 1: The Synthetic Web Sling

The synthetic web sling represents a significant evolution in lifting technology, offering a gentle yet strong alternative to traditional steel slings. Its very nature speaks to a concern for the object being lifted. When you are hoisting a finely painted machine, a polished stone slab, or a sensitive piece of aerospace equipment, the last thing you want is for the lifting device to leave a scar. This is where the web sling excels.

Material and Construction

Web slings are typically fabricated from either nylon or polyester webbing. The choice between these two materials is not arbitrary. Nylon possesses a greater degree of stretch than polyester—a characteristic that can be advantageous for absorbing shock loads, but detrimental if precise load control is needed. Polyester, conversely, exhibits minimal stretch, making it the preferred choice for most general lifting applications where load stability is paramount.

The construction itself involves weaving high-tenacity synthetic yarns into a flat webbing of a specified width. This webbing is then cut to length and sewn into various configurations, such as an endless loop (Type 5) or with eyes at each end (Type 3 or 4). The eyes—the loops used for connection—are a point of careful engineering. They are often reinforced with an extra layer of webbing to resist the abrasion that occurs at the bearing points where the sling connects to hardware like shackles or crane hooks. The quality of a web sling can often be judged by the precision and robustness of its stitching. Reputable manufacturers employ locked stitches that prevent unraveling even if one part of the thread is compromised.

Advantages and Applications

The primary virtue of the web sling is its soft, wide surface. Unlike a wire rope or chain, which concentrates the load along a narrow line, a web sling distributes the pressure over its entire width. This minimizes crushing forces and protects the load from scratches, dents, and other forms of surface damage. For industries like manufacturing, woodworking, and art installation, this characteristic is indispensable.

Their lightweight nature is another significant benefit. A rigger can easily carry several web slings to a job site, reducing fatigue and improving efficiency. They are also flexible and easy to handle, allowing them to be positioned accurately around the load. This ease of use, however, should not be mistaken for a lack of strength. High-quality web slings can achieve impressive Working Load Limits, making them suitable for a wide range of lifting tasks. Their application is particularly prominent in situations requiring a choker hitch on smooth, cylindrical objects or a basket hitch to support a delicate load from underneath. The extensive range of synthetic textile slings available today offers solutions for nearly any load-handling challenge where surface protection is a priority.

Limitations and Inspection

The very properties that make web slings desirable also define their limitations. Their susceptibility to damage is their greatest vulnerability. A sharp edge on a load can act like a knife, severing the sling’s fibers with surprising ease. For this reason, it is an absolute rule that softeners or wear pads must be used to protect the sling from any corner or edge with a radius smaller than the sling’s thickness.

Exposure to the environment also takes a toll. Ultraviolet (UV) radiation from sunlight degrades the synthetic fibers over time, causing them to lose strength and become brittle. This is why slings should never be stored in direct sunlight. Chemical exposure is another grave concern. While polyester is resistant to many common acids and bleaching agents, it is vulnerable to alkaline substances. Nylon, on the other hand, is resistant to alkalis but can be destroyed by acids. A rigger must know the chemical environment of the lift and select the appropriate material.

Inspection of a web sling must be a meticulous, tactile process. Before each use, the entire surface of the sling must be checked for signs of damage. The rejection criteria are unambiguous, as outlined by the Occupational Safety and Health Administration (OSHA, 2022). Any sling exhibiting acid or caustic burns, melting or charring of any part, snags, punctures, tears, or cuts must be removed from service immediately. Broken or worn stitching in the load-bearing splices is another critical failure point. A web sling that has been tied into a knot or has experienced excessive abrasive wear should also be discarded. There is no room for sentiment or thrift when it comes to a damaged sling; its retirement is a necessary act to protect lives.

Type 2: The Synthetic Round Sling

If the web sling is a belt, the round sling is a rope made of a seemingly endless skein of yarn, encased in a protective sleeve. It represents a refinement of synthetic lifting technology, pushing the boundaries of strength-to-weight ratio and flexibility. The round sling is a marvel of simple, effective design.

Material and Construction

The heart of a round sling is its core: a continuous loop of high-performance polyester yarn. These yarns are the load-bearing element. There is no sewing, weaving, or splicing in the core; it is a single, unbroken hank of fibers. This construction method eliminates the localized stress points that can occur at seams or stitches, distributing the load evenly throughout the entire structure of the sling.

This load-bearing core is protected from the elements by a seamless polyester cover, often a double-walled tube. The cover itself has no significant load-bearing capacity. Its primary functions are to hold the core yarns together in a uniform bundle and to protect them from abrasion, cuts, and environmental degradation. The color of the cover is not merely for aesthetics; it is part of an internationally recognized color-coding system that indicates the sling’s Working Load Limit. A purple cover, for example, typically signifies a WLL of one metric ton in a straight lift, while a green cover signifies two tons, and so on. This system provides a quick, visual confirmation of the sling’s capacity, reducing the chance of human error.

Advantages and Applications

The round sling’s greatest strengths are its extreme flexibility and its ability to conform to the shape of the load. Because it is essentially a soft, pliable tube, it provides a near-perfect grip on irregularly shaped or complex objects. When used in a choker hitch, it snugs down tightly, providing excellent load control. In a basket hitch, it cradles the load securely. This adaptability makes it a favorite in many industries, from construction and manufacturing to entertainment rigging, where it might be used to hoist delicate stage lighting or scenery.

Like web slings, round slings are lightweight and easy to handle, but they often boast a higher capacity for a given size. The core yarns can be packed densely, creating a sling that is both compact and immensely strong. Another subtle but important advantage is that the load-bearing core yarns can shift slightly within the cover. This means that if a lift is repeated multiple times, the wear points are not always in the exact same spot, which can help to extend the sling’s service life compared to a web sling where wear is more localized.

Limitations and Inspection

The round sling shares the same primary vulnerability as its flat-webbed cousin: susceptibility to cuts and abrasion. The cover provides a first line of defense, but once it is breached, the load-bearing core yarns are exposed and can be easily damaged. As with web slings, the use of protective pads at all corners and edges is not optional; it is a fundamental requirement for safe use.

The inspection process for a round sling requires a different kind of attention. The inspector must feel and scrutinize the entire length of the sling. The primary rejection criteria involve the cover. If the cover is cut, torn, or punctured to the extent that the core yarns are visible, the sling must be destroyed. Similarly, signs of melting, charring, or chemical damage to the cover warrant immediate removal from service. The inspector should also feel for any unusual stiffness, lumps, or voids in the core, which could indicate internal damage, such as broken or bunched-up fibers, even if the cover appears intact. A round sling with a missing or illegible identification tag is also unusable, as its capacity cannot be verified. The integrity of the entire system relies on the user’s ability to trust the information provided by the manufacturer, a trust that is embodied in the tag. This principle of trust and verification is a cornerstone of the philosophy of a reliable rigging products manufacturer like the one described by linkedin.com.

Type 3: The Wire Rope Sling

We now transition from the soft, synthetic world to the rugged domain of steel. The wire rope sling is perhaps the most iconic piece of rigging equipment, a ubiquitous presence on construction sites, in shipping ports, and in heavy industrial facilities. It is the embodiment of industrial strength, designed for work that is often dirty, abrasive, and demanding.

Material and Construction

A wire rope is a complex mechanical device. It is not a simple, solid wire. Instead, it is composed of numerous individual steel wires that are helically laid (twisted) together to form a strand. Multiple strands are then helically laid around a central core to form the finished rope. This intricate construction gives wire rope its unique combination of strength, flexibility, and resistance to bending fatigue.

The core is a critical component. It can be a fiber core (FC), typically made of natural or synthetic fiber, which provides flexibility and serves as a reservoir for lubricant. Or it can be an independent wire rope core (IWRC), which is a smaller wire rope in its own right. An IWRC provides greater strength and superior resistance to crushing, making it the standard for most heavy-duty lifting slings.

The grade of steel used is also a determining factor in the rope’s capacity. Extra Improved Plow Steel (EIPS) is a common standard, while Extra Extra Improved Plow Steel (EEIPS) offers approximately 10% greater strength. These ropes are then fabricated into slings by forming eyes or loops at the ends. The most common method for this is the Flemish eye splice, a technique where the rope is unlaid, looped back, and then re-laid into itself, with the loose ends secured by a swaged metal sleeve. This method is highly secure and efficient.

Wire Rope Sling Inspection Criteria

A rigorous inspection protocol is the only way to ensure the continued safety of wire rope slings for rigging. The following table details common rejection criteria based on standards like ASME B30.9. A sling must be removed from service if any of these conditions are present.

| Damage Type | Rejection Criteria | Rationale for Removal |

|---|---|---|

| Broken Wires | 10 or more randomly distributed broken wires in one rope lay; or 5 or more broken wires in one strand in one rope lay. | Indicates fatigue and loss of strength. Broken wires can also create a severe puncture hazard for handlers. |

| Kinking/Crushing | Any visible kinking, crushing, bird caging, or other damage that distorts the rope structure. | Distorted rope structure leads to uneven load distribution among the strands and wires, severely weakening the sling. |

| Heat Damage | Any evidence of heat damage, such as discoloration of the wires, loss of lubrication, or melted metal from arc welding. | Heat alters the metallurgy of the steel, making it brittle and significantly reducing its strength and ductility. |

| Corrosion | Severe corrosion with obvious pitting or broken wires at the corrosion site. | Corrosion reduces the metallic cross-sectional area of the rope, directly reducing its strength and making it more susceptible to fatigue. |

| Worn Fittings | Cracks, distortion, or excessive wear (typically more than 10% of the original dimension) on any end fitting, hook, or master link. | Damaged fittings can fail under load, leading to a complete and sudden release of the load. |

| Core Protrusion | Protrusion of the IWRC or fiber core from between the strands. | Indicates a broken or slipped core, which compromises the rope’s structural integrity and support for the outer strands. |

Advantages and Applications

The primary advantage of a wire rope sling is its robust nature. It offers a good balance of strength, abrasion resistance, and resistance to cutting that synthetic slings cannot match. While a sharp edge can still damage a wire rope, it is far more resilient than a web or round sling in this regard. Its ability to withstand higher temperatures also expands its range of applications into environments like foundries and steel mills, where synthetic slings would quickly fail.

Wire rope slings are the general-purpose workhorses of the heavy lifting world. They are used for everything from lifting structural steel beams and concrete panels in construction to loading and unloading cargo in maritime operations. Their relative stiffness can be an advantage when trying to pass the sling under a load or through a narrow opening. The sheer variety of available end fittings—from standard eyes to hooks, shackles, and specialized hardware—makes them incredibly versatile. The use of wire rope slings is fundamental to industries like mining, transportation, and oil exploration.

Limitations and Inspection

Despite its ruggedness, wire rope is not indestructible. Its greatest limitation is its relative inflexibility and its potential to damage sensitive or finished load surfaces. The steel wires can easily mar paint, crush soft materials, or dent polished metals. It is also susceptible to kinking if bent around too sharp a radius, which creates a permanent weak spot in the rope.

Corrosion is the natural enemy of steel, and wire rope is no exception. Slings used in marine or chemical environments must be regularly inspected for rust and pitting, which reduce the rope’s metallic cross-section and, therefore, its strength. Proper lubrication is vital not only to prevent corrosion but also to reduce the internal friction between the wires and strands as the rope flexes under load.

The inspection of a wire rope sling is a detailed and unforgiving process. The rigger must look for specific, quantifiable defects. The most common criteria for removal, as detailed in the table above, relate to broken wires. The number of broken wires in a given length of rope (a “rope lay”) is a key indicator of fatigue. Other immediate rejection criteria include kinking, crushing, “bird caging” (a sudden bulging of the outer strands), heat damage, and severe corrosion. As with all other slings for rigging, a damaged wire rope sling must be destroyed to prevent its accidental reuse.

Type 4: The Alloy Chain Sling

We arrive at the final and most formidable member of the rigging sling family: the alloy chain sling. If the wire rope sling is a workhorse, the chain sling is an armored knight. It is designed for the most demanding, abrasive, and high-temperature lifting applications. Its character is one of uncompromising durability and strength.

Material and Construction

Lifting chains are not the ordinary hardware store variety. They are engineered from special grades of alloy steel, most commonly Grade 80, Grade 100, and more recently, Grade 120. These numbers refer to the chain’s nominal tensile strength. For example, Grade 100 chain is approximately 25% stronger than Grade 80 chain of the same size. This high-strength alloy steel is heat-treated to optimize its properties, creating a chain that is not only strong but also ductile, meaning it can stretch significantly before breaking, providing a visual warning of overload.

A chain sling consists of a series of interconnected, welded alloy steel links. It is typically assembled with a master link at the top for connection to the crane hook, and one or more legs of chain, which may be fitted with hooks or other fittings at the bottom. A key feature of modern chain slings is their adjustability. Many are equipped with grab hooks or sling shortening clutches that allow the rigger to shorten a leg, making it easy to balance an uneven load or to accommodate different lift points. This feature provides a level of versatility that is difficult to achieve with other sling types.

Advantages and Applications

The standout advantages of alloy chain slings are their durability, longevity, and resistance to harsh environments. A chain can withstand the kind of impact, abrasion, and rough handling that would quickly degrade a wire rope or destroy a synthetic sling. It is the only sling type suitable for use at very high temperatures, though its capacity must be derated according to the manufacturer’s specifications when exposed to extreme heat.

Their construction also makes them fully repairable. Unlike other sling types, a damaged link or component in a chain sling can be replaced by a qualified person, restoring the sling to its original capacity and extending its service life. This makes the total cost of ownership for chain slings quite favorable over the long term, despite their higher initial purchase price.

Consequently, chain slings are the preferred choice for foundries, steel mills, heavy machine shops, and any application involving the lifting of rough or abrasive materials like scrap metal or precast concrete. Their use in overhead lifting with products like a bridge crane is a common sight in heavy industrial settings. They are also excellent for lifts where the sling must be wrapped around a load with sharp, unforgiving corners (though using corner protection is still best practice).

Limitations and Inspection

The primary limitations of chain slings are their weight and their relative lack of flexibility. Chain is heavy, which can make it cumbersome to handle, especially in larger sizes. This can lead to operator fatigue and an increased risk of manual handling injuries. It is also completely inflexible in one plane, meaning it does not conform to the shape of a load in the way a synthetic or even a wire rope sling can.

Perhaps the most significant risk associated with chain slings is the potential for sudden, brittle failure if they are overloaded, shock loaded, or used in extremely cold temperatures. While the alloy is designed for ductility, extreme abuse can compromise its integrity.

Inspection of a chain sling requires careful, link-by-link examination. The rigger must check for any signs of stretching, which is the most definitive indicator of overload. This is typically measured as wear or an increase in the link’s inside length. Any link that is bent, twisted, or gouged must be flagged. The welds on each link should be inspected for cracks. Wear at the bearing points where links connect is also a concern; a reduction in the diameter of the link material by more than the manufacturer’s recommended amount (often 10%) is cause for removal. As with all other equipment, the identification tag must be present and legible. A chain sling without a tag is an unknown quantity and cannot be used safely. The entire system of safe lifting, from shackles to hooks, depends on this chain of verified information.

Frequently Asked Questions (FAQ)

What is the most important factor when choosing a sling for rigging? The most vital consideration is a comprehensive assessment of the load and the environment. This includes the load’s weight, its shape, the presence of sharp edges, the surface finish, the ambient temperature, and any potential chemical exposure. No single factor is most important; a holistic view is necessary for a safe choice.

How do I know what a sling’s capacity is? Every commercially manufactured sling is required to have a durable identification tag that clearly states its Working Load Limit (WLL) for different types of hitches (e.g., vertical, choker, basket). If this tag is missing, illegible, or damaged, the sling must be removed from service immediately.

Can I repair a damaged sling? Only alloy chain slings can be repaired by replacing damaged components, and this must be done by a qualified person following the manufacturer’s procedures. Synthetic web slings, round slings, and wire rope slings cannot be repaired and must be destroyed when they show signs of damage.

How does the angle of the sling affect the lift? As the angle between the sling and the horizontal decreases, the tension in each sling leg increases dramatically. At a 60-degree angle, the tension in each leg is slightly more than half the load. At a 30-degree angle, the tension in each leg is equal to the full weight of the load. Using angles below 30 degrees is extremely dangerous and generally not recommended.

How often should slings for rigging be inspected? Slings should receive two types of inspections. A visual inspection should be performed by the user before each and every lift. In addition, a thorough, documented inspection must be conducted periodically by a designated competent person. The frequency of these periodic inspections depends on the service, but for most slings, it is at least annually (OSHA, 2022).

What is the difference between a webbing sling and a round sling? A webbing sling is a flat belt of woven synthetic material, ideal for protecting flat, sensitive surfaces. A round sling consists of a core of load-bearing yarns inside a protective cover, making it extremely flexible and perfect for conforming to irregularly shaped loads.

Why is it important to use a reputable manufacturer? A reputable manufacturer, such as one with decades of experience and a broad portfolio from lifting slings to mooring ropes, adheres to strict quality control standards and provides accurate capacity ratings and usage guidelines. Their products are tested and certified, ensuring they meet industry safety standards. Choosing a trusted source is a foundational element of risk management in rigging. You can learn more about a company’s history and commitment to quality by visiting their information pages, like this one on their background about us.

A Concluding Thought on Responsibility

The exploration of slings for rigging takes us through a landscape of materials, forces, and regulations. We have examined the gentle touch of synthetic web, the adaptable embrace of the round sling, the rugged tenacity of wire rope, and the unyielding strength of alloy chain. We have quantified their limits through the concept of the Working Load Limit and visualized the hidden tensions created by sling angles. Yet, to see this subject as merely a collection of technical data would be to miss its deeper humanistic dimension.

Every sling, every shackle, every hook is an instrument in a human endeavor. The decision to use one sling over another, to protect it from a sharp edge, or to retire it from service is not just a technical choice. It is an ethical one. It is a reflection of the value we place on the safety and well-being of our colleagues. A rigger who inspects a sling with meticulous care is not just following a rule; they are exercising a duty of care to the person working beside them. An engineer who specifies the correct sling for a complex lift is designing a system that protects human life. The mastery of rigging is, in the end, a mastery of responsibility. It is the understanding that these simple tools of rope and chain are the critical links in a chain of human trust, and that chain must never be broken.

References

American Society of Mechanical Engineers. (2021). ASME B30.9-2021: Slings. ASME.

Juli Sling Co., Ltd. (2025). How Long Can You Use a Textile Sling?julislings.com

Juli Sling Co., Ltd. (2025). Why is WLL of lifting sling important, and what does it mean?julislings.com

Juli Sling Co., Ltd. (n.d.). Company Profile. LinkedIn. linkedin.com

Occupational Safety and Health Administration. (2022). 1910.184 – Slings. United States Department of Labor. osha.gov

Pyper, G. (2018). An analysis of the factors that contribute to crane-related fatalities in the construction industry. The University of New Brunswick. unb.ca

Sulowski, A. C. (2011). Inspection of Wire Rope. Sulowski Fall Protection. wireropecommittee.com