How Is a Wire Rope Sling Measured? A Comprehensive Guide for Industrial Lifting Applications

January 20, 2026

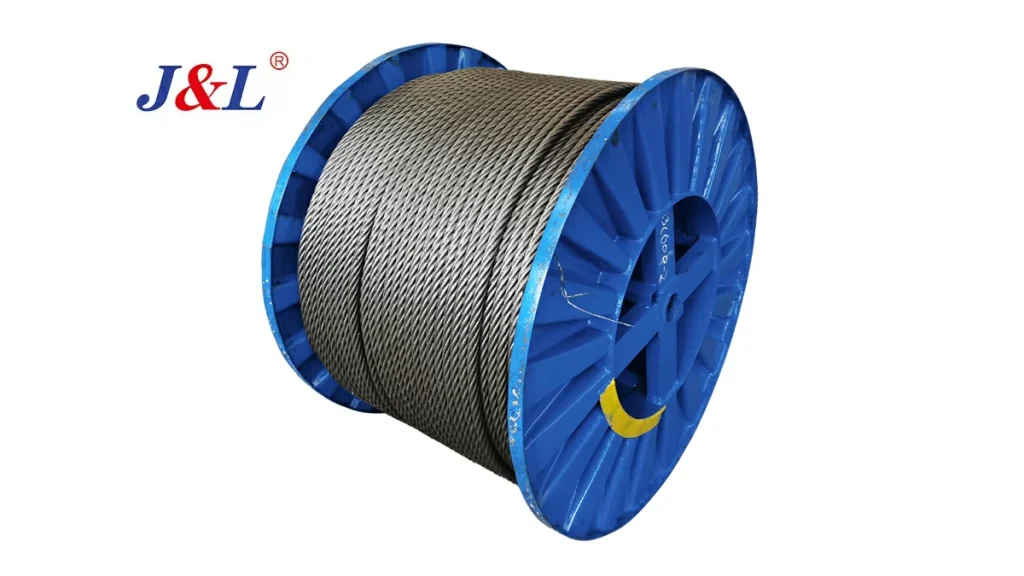

Wire rope slings are a crucial component in industrial lifting, widely used across various sectors like construction, manufacturing, and logistics. Whether you’re lifting heavy machinery, equipment, or delicate items, understanding how a wire rope sling is measured is essential for safety, efficiency, and compliance with industry standards.

This article explores how wire rope slings are measured, the key factors affecting their performance, and why selecting the correct measurements is critical for achieving optimal lifting results.

Key Measurements for Wire Rope Slings

To effectively measure a wire rope sling, it’s important to understand the key aspects that influence its capacity and performance. These include the length of the sling, the diameter of the rope, and its load-bearing capacity. Let’s explore each measurement in detail.

1. Length of the Wire Rope Sling

The length of a wire rope sling is one of the most essential measurements. It is defined as the distance between the two eyes (loops) or the rope’s end to the attachment point. The correct length ensures the sling can perform its intended lifting function without compromising safety.

To measure the length:

- Step 1: Lay the wire rope sling flat on a clean surface.

- Step 2: Measure from eye to eye, or from the rope’s end to the first attachment point.

- Step 3: Verify the length against the manufacturer’s specifications.

2. Diameter of the Wire Rope

The diameter of the wire rope impacts the sling’s strength, flexibility, and load-bearing capacity. A larger diameter rope can carry a heavier load. Measuring the diameter correctly ensures the rope meets the required safety standards for specific applications.

To measure the diameter:

- Step 1: Use a caliper to measure the thickest part of the rope.

- Step 2: Take measurements at multiple points to check for uniformity.

- Step 3: Compare these measurements with manufacturer specifications.

3. Load Capacity of the Wire Rope Sling

The load capacity indicates how much weight the sling can safely lift without failing. This is influenced by the rope’s material, construction type, and diameter. The higher the tensile strength of the rope material, the greater its load capacity.

To determine load capacity:

- Step 1: Understand the rope’s construction (e.g., 6×19, 6×36).

- Step 2: Use load capacity charts or manufacturer information.

- Step 3: Apply a safety factor for extra assurance during use.

Types of Wire Rope Sling Construction

Wire rope slings are available in different construction types, which directly affect their flexibility, strength, and suitability for various lifting tasks. Common types include the 6×19 and 6×36 constructions.

1. 6×19 Construction

The 6×19 construction consists of six strands, each containing 19 wires. It provides excellent flexibility, making it suitable for general-purpose lifting applications. This construction type is ideal when the sling needs to bend frequently.

2. 6×36 Construction

The 6×36 construction features six strands of 36 wires and is designed for heavy-duty lifting tasks. This construction provides higher strength and durability, making it suitable for heavy machinery lifting and other high-stress applications.

Selecting the Right Wire Rope Sling for Your Lifting Application

Choosing the right wire rope sling for your specific lifting needs requires considering the application environment, load type, and the rope’s construction. For instance, if you’re lifting heavy machinery in harsh weather conditions, you may need a sling with extra durability and corrosion resistance.

Environmental Factors

If your lifting operations take place in harsh environments, such as coastal areas with high salt exposure, it’s essential to select a rope sling made from corrosion-resistant materials. Corrosion-resistant coatings help extend the lifespan of the wire rope sling, ensuring reliable performance in extreme conditions.

Maintenance and Inspection of Wire Rope Slings

Regular inspection and maintenance are vital to ensure the safety and efficiency of your wire rope slings. A damaged or worn sling could fail during use, leading to accidents or delays in operations.

How to Inspect Wire Rope Slings

- Step 1: Inspect for any visible signs of wear, broken wires, or corrosion.

- Step 2: Check the eyes for deformations or wear.

- Step 3: Ensure the sling’s overall integrity by performing load tests as required.

By following these steps, you can ensure that your wire rope sling remains in top condition, enhancing safety and performance.

For high-quality wire rope slings designed to meet your industrial lifting needs, contact Julisling. Our team of experts is ready to help you select the best lifting equipment for your specific requirements.

Frequently Asked Questions (FAQ)

Q1: How often should I inspect my wire rope slings?

A1: It is recommended to inspect wire rope slings before every use, focusing on signs of wear, corrosion, and damage. Regular inspections prevent failures and ensure safe lifting.

Q2: Can wire rope slings be repaired?

A2: Minor repairs can be made, but it is typically safer to replace damaged slings to maintain the necessary strength and safety standards.

Q3: What are the different types of wire rope sling constructions?

A3: Common constructions include 6×19 and 6×36. The choice depends on the flexibility required and the weight of the load being lifted.

About Julisling

Julisling is a trusted steel wire rope supplier, specializing in high-quality wire rope slings and lifting equipment. With years of industry expertise, we provide tailored lifting solutions that meet the highest safety and durability standards.