An Actionable 5-Point Checklist for Selecting a Round Sling for Heavy Lifting

September 16, 2025

Abstract

The selection of appropriate rigging equipment is a foundational element of safety and efficiency in material handling operations. This document provides a comprehensive examination of the criteria for selecting a round sling for heavy lifting. It delves into the material science of synthetic fibers, primarily polyester and nylon, contrasting their properties with traditional steel wire rope and chain slings. The analysis extends to the critical importance of understanding and correctly applying Working Load Limits (WLL), which are influenced by the sling's construction, material, and the geometry of the hitch configuration. A systematic, five-point framework is presented to guide operators and safety managers through the selection process. This framework covers material composition, load capacity verification, hitch type selection, pre-use inspection protocols, and the application of protective measures against environmental and mechanical damage. The objective is to foster a deeper, more nuanced understanding of sling mechanics and safety, moving beyond mere compliance to a culture of proactive risk management in heavy lifting scenarios.

Key Takeaways

- Verify the sling's material is compatible with the load and environment.

- Always match the sling’s Working Load Limit (WLL) to the lift's requirements.

- Select the correct hitch type, as it directly affects the sling's capacity.

- Conduct a thorough pre-lift inspection for any signs of damage or wear.

- Use proper corner protection when choosing a round sling for heavy lifting.

- Ensure the identification tag is present, legible, and accurate.

Table of Contents

- Scrutinizing the Material: The Foundational Choice

- Deciphering Load Capacity: The Science of Strength

- Mastering the Hitch: Geometry and Force Distribution

- The Imperative of Inspection: A Pre-Lift Ritual

- Employing Protection: Shielding Slings from Harm

- Frequently Asked Questions

- Conclusion

- References

Scrutinizing the Material: The Foundational Choice

The journey toward a safe and successful lift begins not with the crane or the hoist, but with the humble, yet indispensable, connection to the load itself: the lifting sling. When considering a round sling for heavy lifting, the first and most consequential decision revolves around its material composition. This is not a trivial choice; it is the very foundation upon which the safety of the entire operation rests. The material dictates the sling's strength, its flexibility, its resistance to environmental factors, and its interaction with the object being lifted. To choose a material is to make a statement about the nature of the load and the conditions of the lift. Are we lifting a sensitive, finished product that cannot be scratched, or a rugged piece of raw steel? Will the lift occur in a controlled indoor environment or outdoors, exposed to sunlight, chemicals, and fluctuating temperatures?

Thinking about this decision is akin to a structural engineer selecting the right grade of steel for a bridge. The forces involved are immense, and the consequences of a miscalculation are severe. Let us, therefore, explore the world of sling materials with the diligence it deserves, moving from the modern marvel of synthetic fibers to the time-tested strength of steel.

The Heart of the Sling: Synthetic Fibers

Modern round slings are a testament to advancements in polymer science. At their core, they consist of a continuous, endless loop of high-tenacity synthetic yarn, typically polyester. Imagine thousands of incredibly strong, tiny threads bundled together, all working in unison. This load-bearing core is then encased in a protective, non-load-bearing cover, which is often a double-walled woven jacket. This jacket serves two purposes: it holds the core yarns in their proper orientation and, crucially, protects them from external damage like cuts, abrasion, and UV degradation.

The beauty of this construction lies in its combination of strength and gentleness. Unlike their steel counterparts, synthetic slings are lightweight, making them easier to handle and reducing the risk of ergonomic injuries for riggers. Their soft, pliable nature means they conform to the shape of the load, distributing pressure more evenly and significantly reducing the likelihood of scratching, denting, or crushing the object being lifted (H&H Industrial Lifting, 2024). This makes them ideal for lifting items with sensitive surfaces, such as painted components, machined parts, or fiberglass boat hulls.

Polyester vs. Nylon: A Tale of Two Polymers

While polyester is the most common material for round slings, nylon is also a prevalent choice in the broader category of synthetic webbing slings. Understanding their distinct personalities is key to proper selection. Think of polyester as the steady, reliable workhorse. Its most notable characteristic is its low stretch. When a load is applied, a polyester sling will elongate by only about 3%. This minimal stretch provides excellent load control, which is vital when placing heavy equipment with precision. Polyester also boasts superior resistance to acids and bleaching agents, making it a safer choice in certain chemical environments.

Nylon, on the other hand, is the more elastic and shock-absorbing member of the family. It can stretch by approximately 6-10% at its rated capacity. While this elasticity can be a disadvantage in lifts requiring high precision, it is a significant benefit when there is a potential for shock loading. The stretch allows the sling to absorb some of the energy from a sudden jolt, protecting both the load and the lifting equipment. Nylon is also known for its excellent resistance to alkalis and certain chemicals like ethers and alcohols. However, it is weakened by acids and should not be used in such environments.

A simple mental exercise: if you were lifting a multi-ton, precisely calibrated scientific instrument onto a pedestal, which would you choose? The low-stretch, predictable nature of polyester would be the superior option. If you were recovering a vehicle from a ditch where some dynamic, jerking forces might be unavoidable, the shock-absorbing quality of nylon could be beneficial.

Sling Material Comparison

| Feature | Polyester Slings | Nylon Slings | Wire Rope Slings | Chain Slings |

|---|---|---|---|---|

| Stretch at WLL | Low (~3%) | High (~6-10%) | Very Low (<1%) | Very Low (<1%) |

| Load Protection | Excellent; soft and pliable | Excellent; soft and pliable | Poor; can mar or crush | Poor; can gouge or scratch |

| Weight | Very Light | Very Light | Heavy | Very Heavy |

| Chemical Resistance | Good against acids | Good against alkalis | Poor | Good to Excellent |

| Heat Resistance | Poor (Max ~90°C/194°F) | Poor (Max ~90°C/194°F) | Good | Excellent |

| Cost | Low | Low | Medium | High |

| Abrasion/Cut Risk | High without protection | High without protection | Medium | Low |

When Synthetics Aren't Enough: Considering Wire Rope and Chain

Despite the many advantages of synthetic slings, they are not universally applicable. Certain industrial environments and load types demand the brute strength and resilience of steel. This is where wire rope slings and chain slings enter the picture.

Wire rope slings, constructed from steel wires twisted into strands and then laid around a core, offer a good balance of strength, abrasion resistance, and flexibility compared to chain. They are a common sight in construction and general industry, often used for lifting raw materials like concrete sections or steel beams (Rigging Canada, 2025). While they are more resistant to cutting and abrasion than synthetic slings, they are not immune. A sharp corner on a steel I-beam can still damage a wire rope sling, and they are susceptible to kinking, which permanently compromises their strength.

Chain slings represent the pinnacle of durability and strength in the lifting world. Composed of high-grade alloy steel links, they are the go-to choice for the harshest environments, such as steel mills, foundries, and heavy-duty machine shops (Juli Sling, 2025). Their primary advantages are their exceptional resistance to cutting, abrasion, and high temperatures. A round sling would be instantly destroyed by the heat of a freshly cast metal part, but a chain sling can handle it with ease. However, this toughness comes at a cost. Chains are extremely heavy, cumbersome to handle, and offer no protection to the load's surface. They can easily damage fragile or finished goods.

The selection process, therefore, becomes a thoughtful evaluation of trade-offs. The gentleness and flexibility of a round sling for heavy lifting must be weighed against the rugged, heat-resistant nature of chains. The lightweight handling of synthetics must be compared to the abrasion resistance of wire rope.

Environmental Factors: The Silent Saboteurs

A sling's life is not lived in a vacuum. The environment in which it operates can be just as damaging as a sharp edge or an overload. Sunlight, specifically its ultraviolet (UV) radiation, is a significant enemy of synthetic fibers. Prolonged exposure causes the polymer chains to break down, leading to a loss of strength. This is why slings should always be stored in a cool, dark, dry place away from direct sunlight. The protective outer cover of a round sling contains UV inhibitors, but it is not impervious. Fading of the cover's color is a visual indicator of UV exposure and a sign that the sling's strength may be compromised.

Chemical exposure is another critical consideration. As noted, polyester and nylon have different chemical resistances. A polyester sling that is perfectly safe in an acidic environment could be dangerously weakened by a strong alkaline solution, and vice versa for nylon. Before any lift in a chemical plant, processing facility, or any area where chemical exposure is possible, the specific chemicals present must be identified and cross-referenced with the sling manufacturer's chemical resistance chart. Ignorance in this area is not an excuse; it is a direct path to failure.

Temperature also plays a vital role. Synthetic slings, both polyester and nylon, have a relatively narrow operating temperature range, typically from -40°C to 90°C (-40°F to 194°F). Using them above this range will cause permanent, irreversible damage to the fibers, drastically reducing their capacity. For high-heat applications, chain or specialized high-temperature wire rope slings are the only safe options.

Deciphering Load Capacity: The Science of Strength

Once the appropriate material has been selected, the next critical step is to ensure the sling has the brute strength to handle the task. This is not a matter of guesswork or estimation. It is a precise science governed by engineering principles and international standards. The concept of Working Load Limit (WLL) is central to this science. To ignore the WLL is to gamble with the load, the equipment, and, most importantly, the lives of everyone in the vicinity of the lift. A comprehensive understanding of WLL, how it is determined, and how it is affected by the lifting configuration is non-negotiable for anyone involved in rigging.

Let us think of the WLL as a strict, legally binding speed limit for the sling. Exceeding it, even for a moment, introduces extreme risk and the potential for catastrophic failure. Our task is to become fluent in the language of load capacities, from the color codes that signal strength to the calculations that account for the physics of the lift.

Understanding Working Load Limit (WLL)

The Working Load Limit (WLL), sometimes referred to as the Rated Capacity, is the maximum mass or force that a piece of lifting equipment is certified by the manufacturer to handle under a specific set of conditions. It is not the same as the breaking strength. The actual breaking strength of a new round sling is significantly higher than its WLL. The ratio between the breaking strength and the WLL is known as the design factor or safety factor.

For lifting slings, this design factor is typically at least 5:1 for synthetics and wire rope, and 4:1 for chain. This means a polyester round sling with a WLL of 2,000 kg is engineered to have a minimum breaking strength of 10,000 kg. Why such a large margin? This factor of safety is not superfluous; it is a carefully calculated buffer designed to account for variables that are difficult to control in the real world. These include minor, undetected wear; the potential for shock loading (a sudden jerk or bounce of the load); the dynamic forces of swinging or rotating the load; and the inherent uncertainties of a lifting environment. The safety factor is a life-saving cushion built into the system. Relying on it by intentionally exceeding the WLL is a grave error, as it erodes the very safety margin designed to protect you.

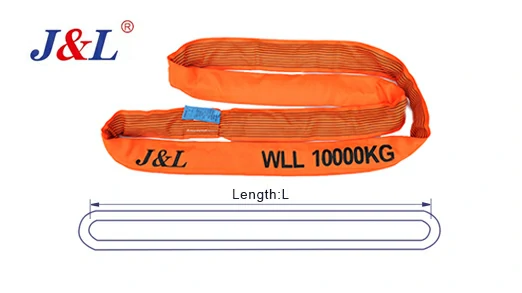

The Color Code System: A Visual Language of Strength

To simplify the identification of a round sling's capacity, the industry has adopted a standardized color-coding system for the outer jacket. This brilliant system allows a rigger to identify the sling's vertical WLL at a glance, reducing the chance of accidentally selecting an undersized sling. While you should always confirm the capacity by reading the tag, the color provides an immediate and intuitive first check.

This visual language is consistent across most global markets, including Europe, the United States, and many parts of Asia and the Middle East, though minor regional variations can exist. The number of black stitching lines on the sling's body can also indicate the WLL, with each line often representing one tonne (or 2,000 lbs) of vertical capacity, providing a redundant visual cue.

Standard Round Sling Color Codes and Capacities

| Sling Color | Vertical WLL (Metric Tonnes) | Vertical WLL (Pounds) |

|---|---|---|

| Purple | 1 Tonne | 2,600 lbs |

| Green | 2 Tonnes | 5,200 lbs |

| Yellow | 3 Tonnes | 8,400 lbs |

| Grey/Tan | 4 Tonnes | 10,600 lbs |

| Red | 5 Tonnes | 13,200 lbs |

| Brown | 6 Tonnes | 16,800 lbs |

| Blue | 8 Tonnes | 21,200 lbs |

| Orange | 10+ Tonnes | 26,400+ lbs |

| Note: These values are typical and may vary by manufacturer. Always confirm capacity via the sling's identification tag. |

The Impact of Hitch Type on Capacity

A crucial point that is often misunderstood is that the WLL printed on the tag and indicated by the color applies only to a specific lifting configuration: a straight, vertical, single-leg lift (a "vertical hitch"). The moment you change the way the sling is rigged, its effective capacity changes. This is not a flaw in the sling; it is a simple matter of physics. The geometry of the lift dictates how the load's force is distributed through the sling.

The three primary hitch types are the vertical hitch, the choker hitch, and the basket hitch.

- Vertical Hitch: A single sling leg connects the lifting hook directly to the load. The tension on the sling is equal to the weight of the load. The capacity is 100% of the sling's rated WLL.

- Choker Hitch: The sling is wrapped around the load and passed back through itself. This creates a constricting grip, which is useful for securing loose bundles or objects without dedicated lifting points. However, the sharp bend where the sling passes through itself creates a point of high stress and reduces the sling's effective capacity. A standard choker hitch typically reduces the WLL to 80% of its vertical rating.

- Basket Hitch: The sling is passed under the load, and both ends are connected to the lifting hook. In a true vertical basket hitch (where the sling legs are perfectly parallel), the load is distributed across two legs of the sling, effectively doubling its capacity to 200% of its vertical WLL. However, as soon as the legs spread apart and form an angle, the capacity begins to decrease dramatically. This topic of sling angles is so important it deserves its own discussion.

Imagine the sling's capacity as a budget. A vertical hitch uses the budget efficiently. A choker hitch imposes a "service fee," reducing the available budget. A basket hitch can potentially "pool resources" to increase the budget, but only under very specific geometric conditions. You can find a wide range of high-quality polyester round slings designed for various hitch configurations and load requirements.

Calculating the Total Load: Beyond the Obvious

The final piece of the capacity puzzle is accurately determining the total weight of the object being lifted. This seems straightforward, but it can be deceptive. The "total load" is not just the stated weight of the object. It must also include the weight of all rigging hardware being used—the shackles, spreader beams, hooks, and the sling itself. For very heavy lifts, the weight of the rigging can be substantial and must be factored into the crane's total load calculation.

Furthermore, one must consider the center of gravity (CG) of the load. If the lifting points are not directly above the CG, the load will tilt, and the tension on the individual sling legs will not be equal. The sling legs on the side that tilts down will bear a disproportionately high share of the weight, potentially exceeding their WLL even if the total weight of the load is within the combined capacity of the slings. Rigging a load with an offset CG requires careful planning and often involves using slings of different lengths or adjusting attachment points to ensure the load remains level and the forces are distributed as intended.

Finally, the specter of shock loading must always be on a rigger's mind. Rapidly accelerating or decelerating a lift, or allowing the load to snag and then break free, can momentarily multiply the forces on the sling. These dynamic forces can easily exceed the WLL and even the sling's breaking strength. Smooth, controlled operation of the lifting equipment is a critical component of sling safety.

Mastering the Hitch: Geometry and Force Distribution

We have established that the way a sling is attached to a load—the hitch—is not merely a matter of convenience. It is an act of applied physics that fundamentally alters the forces acting upon the sling. A rigger is, in essence, a practical geometer, using angles and configurations to safely and efficiently control immense weights. Each type of hitch has its own personality, its own set of advantages, and its own inherent risks. To master the hitch is to understand this personality and to deploy it with intention and foresight. The choice of hitch affects not only the sling's capacity but also the stability and control of the load throughout the lift.

Let's delve into the mechanics of the three fundamental hitches, visualizing the flow of forces and understanding why a simple change in angle can be the difference between a safe lift and a failure.

The Vertical Hitch: Simplicity and Direct Force

The vertical hitch is the most straightforward of all rigging configurations. It involves a single sling connecting a lifting point on the load directly to the hook of the hoist or crane. In this setup, the force on the sling is simple and direct: it is equal to the weight of the load being lifted (plus the minor weight of the sling itself). If you are lifting a 1,000 kg object with a single vertical hitch, the tension in the sling is 1,000 kg.

This simplicity is its greatest strength. There are no complex angle calculations or capacity reductions to consider (beyond the sling's inherent WLL). It is the baseline against which all other hitches are measured. The WLL printed on a sling's tag is its capacity in a vertical hitch. However, this configuration is only suitable for loads that have a single, stable lifting point located directly above the center of gravity. Attempting to lift a wide or unbalanced object with a single vertical hitch will cause it to tip and become unstable, creating a significant hazard.

The Choker Hitch: A Gripping Embrace

The choker hitch provides a solution for lifting objects that lack convenient lifting points, such as pipes, shafts, or bundles of material. The sling is wrapped around the circumference of the load, and one end is passed through the eye on the other end, forming a noose that tightens as the lift begins. This "choking" action provides a secure grip on the load.

However, this security comes at a price. The point where the sling passes through its own eye and bends sharply back on itself creates a significant stress concentration. Think of trying to sharply bend a garden hose; the point of the bend is under strain and the flow is restricted. Similarly, the load-carrying core yarns of the sling are not able to align perfectly at this point, and some are forced to carry more load than others. To account for this, the capacity of a sling in a choker hitch is reduced. A common rule of thumb is that a choker hitch has about 80% of the capacity of a vertical hitch. This reduction factor can be even greater if the angle of the choke is less than 120 degrees. The sharper the bend, the greater the reduction in strength. A rigger must always consult the manufacturer's specific capacity charts for choker hitches.

The Basket Hitch: Sharing the Burden

The basket hitch cradles the load. The sling passes underneath the object, and both eyes are placed on the lifting hook. If the legs of the sling are perfectly vertical and parallel (a 90-degree angle to the horizontal), the load is evenly distributed between the two legs of the sling. In this ideal scenario, a basket hitch can lift double the sling's vertical WLL. For example, a sling rated for 2 tonnes in a vertical hitch can lift 4 tonnes in a proper, vertical basket hitch.

This is where the critical importance of sling angles comes into play. The ideal vertical basket hitch is often difficult or impossible to achieve. As soon as the sling legs spread apart, forming an angle with the vertical, the tension in each leg begins to increase for the same given load.

Think about it this way: Imagine you and a friend are carrying a heavy suitcase. If you both hold the handle from directly above, you each feel half the weight. Now, imagine you each step to the side, holding the handle from an angle. The suitcase's weight hasn't changed, but your arms will feel a significantly greater strain. You are not only supporting the weight but also pulling against each other. The exact same principle applies to a sling in a basket hitch.

As the angle between the sling leg and the vertical increases, the tension in that leg increases exponentially.

- At a 30-degree sling angle (from vertical), the tension in each leg is about 15.5% higher than half the load.

- At a 45-degree sling angle, the tension is about 41.4% higher.

- At a 60-degree sling angle, the tension in each leg is exactly equal to the total weight of the load. This means each of the two legs is carrying the full weight! The sling is under twice the stress it would be in a vertical basket.

This is why sling angles above 60 degrees from the vertical are strongly discouraged and often prohibited. The forces multiply so rapidly that the sling can become overloaded even with a seemingly light load. A savvy rigger always carries a load angle chart and aims to keep sling angles as small as practically possible, ideally below 45 degrees.

The Imperative of Inspection: A Pre-Lift Ritual

A round sling, for all its strength, is a consumable item. It is subject to wear, tear, and damage from the moment it is put into service. To treat a sling as a permanent, indestructible tool is to court disaster. The practice of diligent, systematic inspection is not a bureaucratic formality; it is an active, life-saving ritual that must be performed before every single lift. A chain is only as strong as its weakest link, and a lift is only as safe as the condition of its sling. The few minutes it takes to properly inspect a sling are the most valuable investment in safety a rigger can make.

The responsibility for this inspection falls on the person using the sling. This individual is the last line of defense against a catastrophic failure. This requires a trained eye, a disciplined approach, and an unwavering commitment to removing any questionable equipment from service.

Establishing a Rigorous Inspection Protocol

Effective inspection is not a casual glance. It should be a formal, tactile process governed by a clear protocol. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the United States and similar organizations worldwide mandate different levels of inspection. Typically, this involves:

- Initial Inspection: Every new sling should be inspected upon receipt from the manufacturer to ensure it is the correct type, capacity, and length ordered, and that it has not been damaged in transit.

- Frequent Inspection: This is the pre-lift check performed by the user before each use. It is a visual and tactile examination of the entire sling.

- Periodic Inspection: A more thorough, documented inspection conducted by a designated, competent person at regular intervals (e.g., monthly or quarterly, depending on the frequency and severity of use). This inspection should be formally recorded in an inspection log for each sling.

This multi-layered approach ensures that damage is caught early, and a sling's condition is continuously monitored throughout its service life.

Visual and Tactile Inspection Checklist: What to Look For

The frequent, pre-lift inspection should be a hands-on process. A rigger should run their hands (while wearing gloves) along the entire length of the sling, feeling for abnormalities while also looking closely. Here is a checklist of the critical "red flags" that should immediately trigger the removal of a sling from service:

- Missing or Illegible Identification Tag: The tag is the sling's birth certificate. If it is missing or unreadable, the sling's capacity, material, and history are unknown. The sling must be removed from service immediately.

- Cuts, Snags, or Holes: Examine the outer cover closely. Any cut or hole is a major concern because it could indicate damage to the load-bearing core yarns beneath. If the core yarns are visible at any point, the sling is unequivocally unsafe.

- Heat or Chemical Damage: Look for areas that are melted, charred, or glazed. This indicates exposure to excessive heat, which permanently weakens the synthetic fibers. Similarly, look for discoloration or stiffness, which can be signs of chemical attack.

- Crushed, Broken, or Damaged Core Yarns: Even if the cover is intact, you must feel the sling's body. If you can feel lumpy, stiff, or broken-up areas, it suggests the internal core yarns have been crushed or broken. The sling will feel different in these areas—less pliable. This is critical damage and requires immediate removal.

- Knots: A knot in any part of the sling can reduce its strength by as much as 50%. Slings should never be knotted.

- Excessive Abrasive Wear: Look for areas where the outer cover has become fuzzy or worn thin. While some surface fuzz is normal with use, excessive wear compromises the cover's ability to protect the core.

- Stitching Damage: Check the stitching on the protective cover. If any of the stitching is broken or pulled, it can compromise the integrity of the jacket.

The Role of Tags and Identification

The identification tag is arguably the most important part of the sling. It is the sole source of authoritative information about its capabilities. According to standards like ASME B30.9, the tag on a synthetic round sling must clearly state:

- The name or trademark of the manufacturer.

- The rated load (WLL) for at least the three primary hitch types (vertical, choker, basket).

- The material of the core and cover.

- The sling's length.

If any of this information is missing or cannot be read, the sling is no longer compliant or safe. Riggers should be trained to protect the tag, perhaps by tucking it away during the lift, to prevent it from being crushed or torn off.

When to Retire a Sling: Recognizing Irreparable Damage

The decision to remove a sling from service should be conservative. The guiding principle is: "When in doubt, throw it out." The cost of a new sling is infinitesimal compared to the cost of an accident. A designated, competent person should make the final determination, but any user has the authority and responsibility to quarantine a sling they deem unsafe.

Once a sling is removed from service due to damage, it must be rendered unusable to prevent it from being accidentally put back into circulation. This is typically done by cutting the sling in half, for example, by cutting the eye or the body. A damaged sling should never be repaired. The construction of a round sling does not allow for safe, reliable repairs. Any attempt to stitch, patch, or otherwise "fix" a damaged sling creates an unknown and unacceptable risk. The only safe course of action is destruction and replacement with a new, certified sling, such as the numerous endless round slings available from reputable suppliers.

Employing Protection: Shielding Slings from Harm

A round sling's greatest virtues—its softness and flexibility—are also the source of its greatest vulnerability. While it protects the load from damage, the sling itself is susceptible to being cut or abraded by the very load it is lifting. To use a synthetic sling without adequate protection against sharp edges or abrasive surfaces is like sending a soldier into battle without a helmet. It is a negligent act that willfully ignores a primary failure mode. The use of sling protection is not an optional accessory; it is an integral part of safe rigging practice.

Protecting your slings is also an act of economic prudence. A high-quality round sling is a valuable tool. Allowing it to be destroyed prematurely by a sharp corner is wasteful. The small cost of a wear pad or cut-resistant sleeve is a wise investment that can dramatically extend the service life of your lifting slings.

The Enemies of a Sling: Abrasion, Cutting, and Heat

Let's personify the threats. The most common enemy is the sharp edge. The corner of a steel plate, the flange of an I-beam, or even the rough edge of a concrete block can act like a knife against the taut fibers of a sling's cover and core. This is not a slow, grinding process; a sling under tension can be severed in an instant by a sharp edge. The industry defines a "sharp edge" as any corner with a radius smaller than the diameter of the sling.

The second enemy is abrasion. This is a slower, more insidious form of damage caused by repeated rubbing against a rough surface, like unfinished concrete or a rusty steel structure. This friction acts like sandpaper, slowly wearing away the protective outer cover and eventually exposing the core yarns to damage.

The third enemy is excessive heat. As discussed, synthetic fibers have a limited temperature range. Contact with hot surfaces, sparks from welding or grinding, or even intense, prolonged friction can melt the fibers, causing an immediate and catastrophic loss of strength.

Types of Sling Protection: Sleeves, Pads, and Guards

Fortunately, a robust arsenal of protective products has been developed to combat these enemies. The selection of the right protection depends on the specific hazard.

- Wear Pads and Sleeves: These are the most common form of protection. They are typically made from a tough material like webbing, leather, or a thick layer of cordura fabric. They are available as movable sleeves that can be positioned along the sling's length or as pads that can be sewn directly onto the sling in high-wear areas. These are primarily designed to protect against abrasion and are not sufficient for protection against sharp, cutting edges.

- Cut-Resistant Protection: For true sharp-edge protection, more advanced materials are required. These products are specifically engineered to resist cutting. They may be constructed from high-performance materials like Dyneema®, molded from durable polyurethane, or even consist of specialized metal-mesh pads. These are placed between the sling and the sharp corner of the load. It's critical to understand that not all "protection" is cut-proof. A standard webbing wear pad offers almost no protection from a true cutting edge.

- Magnetic Protectors: For lifting steel plates or beams, innovative magnetic corner protectors are available. These protectors, often made of durable polymer or aluminum, have powerful magnets embedded in them. They snap directly onto the steel corner, staying in place while the rigger positions the sling, making the process faster and safer.

Matching Protection to the Hazard

The key is to correctly diagnose the hazard and prescribe the right protection. Before the lift, the rigger must inspect the load itself. Are the corners sharp enough to cut a finger? If so, they are sharp enough to cut a sling, and cut-resistant protection is mandatory. Is the surface rough and abrasive, like pre-cast concrete? A heavy-duty webbing wear pad would be appropriate. Will the sling be in contact with a part of the load that may become hot during the process? A specialized heat-resistant sleeve or a different type of sling (like chain) might be necessary.

The protection must also be sized and positioned correctly. It must be large enough to cover the entire area of contact and must be secured so that it cannot slip out of position during the lift. The goal is to ensure that at no point does the body of the round sling for heavy lifting come into direct contact with a potentially damaging surface.

The Economic Sense of Protecting Your Investment

Consider the lifecycle cost. A single unprotected lift on a sharp edge can destroy a brand-new, expensive, high-capacity sling. The cost of that sling, the project delays caused by the incident, and the potential for a catastrophic accident all dwarf the minor cost of a set of corner protectors. A culture of safety that emphasizes sling protection will see its slings last longer, its operations run more smoothly, and its risk of accidents decrease significantly. It is a clear instance where spending a little on prevention yields an enormous return in both safety and financial savings.

Frequently Asked Questions

What is the main difference between a round sling and a webbing sling?

A round sling consists of a continuous loop of load-bearing yarns inside a protective fabric jacket, making it endless. A webbing sling, or flat-eye sling, is constructed from a flat woven strap of material, typically with reinforced eyes or loops at each end. Round slings are generally more flexible and can offer better durability as the internal wear points can be shifted with each use, while webbing slings provide a wider, more stable contact surface on the load.

Can I repair a damaged round sling?

No. A damaged round sling should never be repaired. The integrity of the load-bearing core yarns cannot be reliably restored or inspected after a repair. Any attempt to patch, stitch, or otherwise mend a sling creates an unknown and unacceptable risk. According to safety standards like ASME B30.9, damaged slings must be removed from service and destroyed to prevent reuse.

How does temperature affect a polyester round sling?

Polyester round slings have a specific operating temperature range, typically from -40°C to 90°C (-40°F to 194°F). Exposure to temperatures above this limit will cause irreversible damage to the synthetic fibers, melting them and severely reducing the sling's strength. Similarly, while they perform well in extreme cold, they should not be used for lifting loads that are hot enough to exceed the 90°C limit.

Why is the identification tag on a sling so important?

The identification tag is the sling's official documentation. It provides the essential information a rigger needs to conduct a safe lift, including the manufacturer, the material, and, most critically, the Working Load Limit (WLL) for various hitch configurations. Without a legible tag, the sling's capacity is unknown, making it unsafe and non-compliant with safety regulations. A sling with a missing or unreadable tag must be immediately removed from service.

What is a "design factor" or "safety factor"?

The design factor is the ratio between the sling's minimum breaking strength and its Working Load Limit (WLL). For synthetic round slings, this is typically 5:1 or higher. This means a sling with a WLL of 2 tonnes has been engineered and tested to have a minimum breaking strength of 10 tonnes. This built-in safety margin accounts for dynamic forces, minor wear, and other real-world variables, but it should never be intentionally violated by overloading the sling.

How often do I need to inspect my lifting slings?

Slings must be inspected before every use. This is called a "frequent inspection" and is performed by the user to check for any obvious damage. Additionally, a "periodic inspection" must be conducted by a designated, competent person at regular intervals (e.g., annually, quarterly, or monthly depending on service severity). This more thorough inspection must be documented in a log.

What is the most dangerous sling angle?

Any sling angle in a multi-leg or basket hitch increases the tension on the sling legs. However, the forces increase dramatically as the angle widens. Sling angles greater than 60 degrees from the vertical are considered extremely dangerous because the tension in each sling leg exceeds the total weight of the load. Safe rigging practice dictates keeping sling angles as small as possible, ideally 45 degrees or less.

Conclusion

The process of selecting and using a round sling for heavy lifting is a discipline that marries scientific principle with practical diligence. It is a field where small details have monumental consequences. We have journeyed through the five foundational pillars of this discipline: the careful consideration of material, the precise understanding of capacity, the geometric mastery of the hitch, the unwavering ritual of inspection, and the intelligent application of protection. Each of these elements is interconnected, forming a chain of safety that protects personnel, equipment, and the load itself.

To engage in lifting operations is to assume a profound responsibility. This responsibility cannot be met by simply memorizing rules or casually glancing at a color chart. It requires a deeper, more empathetic understanding—an appreciation for the immense forces at play and a respect for the equipment designed to control them. The choice is not merely between polyester and chain, or between a choker and a basket hitch. The choice is between a culture of assumption and a culture of certainty, between complacency and vigilance. By embracing the principles of rigorous selection, calculation, and inspection, we elevate the practice of rigging from a mere task to a professional craft rooted in an unwavering commitment to safety.

References

H&H Industrial Lifting. (2024, February 26). Choosing the right lifting sling: Round slings vs. web slings. H&H Industrial Lifting. https://www.hhilifting.com/en/news/post/choosing-the-right-lifting-sling-round-slings-vs-webbing-slings

Juli Sling. (2025, January 24). The ultimate guide to different types of webbing slings. https://www.julislings.com/blog/the-ultimate-guide-to-different-types-of-webbing-slings.html

Juli Sling. (n.d.-a). Endless round slings, endless loop sling, round slings lifting. Retrieved January 28, 2025, from

Juli Sling. (n.d.-b). Round sling, round webbing sling. Retrieved January 28, 2025, from

Lift-Sling. (2025, January 1). How to choose the webbing material for lifting slings? China Lifting Slings. https://www.lift-sling.com/how-to-choose-the-webbing-material-for-lifting-slings.html

Lift-Sling. (2025, January 1). What are the differences between webbing slings and round slings? China Lifting Slings. https://www.lift-sling.com/what-are-the-differences-between-webbing-slings-and-round-slings.html

Occupational Safety and Health Administration. (n.d.). Slings. United States Department of Labor. Retrieved January 28, 2025, from

Rigging Canada. (2025, January 1). Lifting sling selection guide.