Are Galvanized Wire Ropes the Best Choice for Outdoor Lifting Tasks?

August 5, 2025

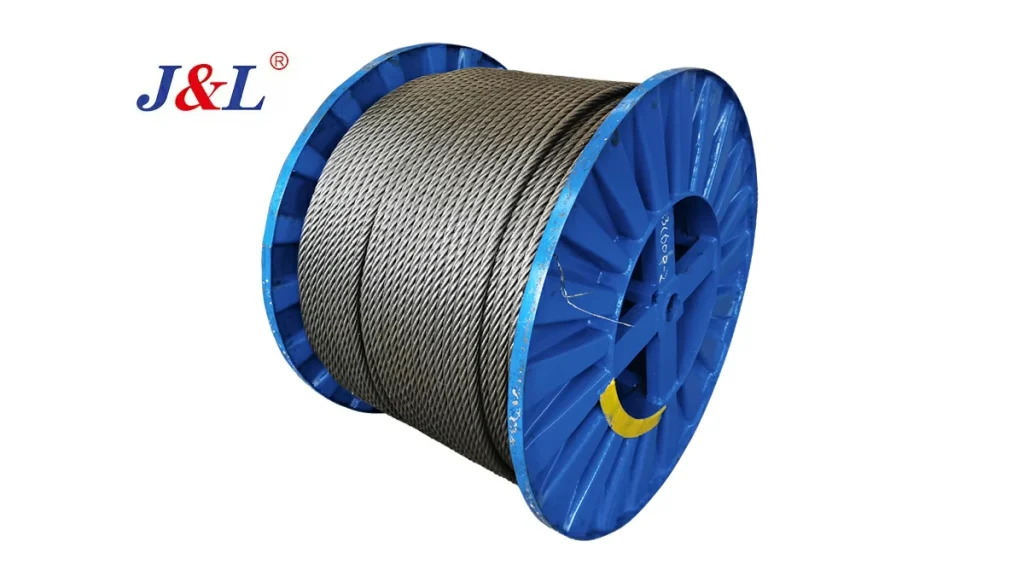

In outdoor lifting applications—where exposure to moisture, temperature extremes, and corrosive environments is constant—choosing the right rigging components is crucial. Among the many options available, galvanized wire ropes have earned a reputation for durability and reliability. But are they truly the best fit for demanding field operations?

At Juli Sling, we specialize in delivering certified lifting solutions for industries that work outside the factory floor—construction, marine, infrastructure, and energy. Our steel wire rope galvanized products are designed to perform where traditional ropes fail and where safety margins leave no room for compromise.

Why Galvanized Wire Ropes Are Built for Harsh Environments

Galvanized wire rope is manufactured by coating steel strands with zinc, either through hot-dip or electroplating processes. This zinc coating serves as a sacrificial layer, shielding the steel underneath from corrosion caused by rain, humidity, salt air, or chemical exposure.

Compared to uncoated ropes, galvanized wire ropes offer:

- Longer service life outdoors

- Reduced maintenance and inspection intervals

- Stable performance even in wet or industrial atmospheres

- Lower total cost of ownership over time

For lifting professionals who operate in unpredictable or remote job sites, this added durability makes galvanized options the safer, more dependable choice.

Typical Use Cases for Galvanized Wire Ropes

Whether you’re working at a coastal construction site or on high-altitude scaffolding, galvanization adds the resilience needed for long-term performance. At Juli Sling, our ropes are manufactured to meet global standards in lifting, tensioning, and securing applications.

Common Outdoor Applications Include:

- Tower and bridge erection

- Crane hoisting systems

- Telecommunication mast rigging

- Dockside and barge lifting

- Renewable energy installations (wind turbine hoists)

- Utility pole and cable line support

These field applications not only demand strength but also resistance to rust, weather fatigue, and structural wear—all areas where galvanized ropes excel.

The Role of the Lifting Sling Supplier

Choosing the right product is only half the challenge—having a knowledgeable lifting sling supplier makes the real difference. Juli Sling doesn’t just provide products—we offer tailored solutions based on project load calculations, environmental conditions, and usage cycles.

As a full-service supplier, we deliver:

- Custom-cut steel wire rope galvanized lengths with end terminations

- Complete sling assemblies (eye hooks, turnbuckles, thimbles, shackles)

- Load test certificates and material traceability

- Coating thickness and corrosion rating details

- Technical guidance for compliance with EN, ISO, and OSHA standards

This hands-on support helps contractors, equipment rental companies, and site engineers make informed, risk-reducing decisions.

What to Consider When Choosing Galvanized Wire Rope

Before placing your next order, it’s important to match the rope’s characteristics with your job’s requirements. Even within the “galvanized” category, there are performance variations that affect usability and longevity.

Key Factors to Evaluate:

- Rope Construction: 6×19 for abrasion resistance, 6×36 for flexibility

- Core Type: IWRC (Independent Wire Rope Core) for strength, fiber core for bendability

- Coating Type: Hot-dip offers better corrosion resistance than electroplated in marine conditions

- Breaking Load: Choose a rope with at least a 5:1 safety factor for lifting

- End Fittings: Ensure compatibility with your lifting gear or tension system

Working with an expert lifting sling supplier like Juli Sling ensures all of these parameters are properly reviewed and verified for safety and performance.

How Juli Sling Supports Outdoor Lifting Projects

With over a decade of experience in the lifting and rigging industry, Juli Sling provides a wide range of galvanized wire ropes designed to perform in the toughest environments. Our manufacturing capabilities allow us to meet custom size, strength, and flexibility requirements, while our logistics team ensures rapid delivery to job sites worldwide.

We also offer inspection-ready labeling, batch documentation, and optional RFID tagging for inventory tracking—ideal for contractors managing large-scale projects with multiple lift points.