Can Synthetic Slings Be Used on Forklift Forks?

July 6, 2025

If you’re in the business of lifting and rigging, you’ve probably wondered: Can synthetic slings be used over a forklift fork? The short answer is no, and here’s why it’s crucial to avoid this practice.

What is the synthetic sling?

Synthetic slings are made of synthetic fiber materials and are used for lifting, traction, tensioning, and carrying ropes or belts. Characteristics of synthetic slings made of different materials:

Nylon: It has high strength and wear resistance, good elasticity, and can withstand large impact loads, but its light resistance and heat resistance are poor. If it is exposed to sunlight or a high-temperature environment for a long time, its performance will decrease.

Polyester: It has high strength, wear resistance, and corrosion resistance, and its light resistance and heat resistance are better than nylon. It has good dimensional stability and is widely used in lifting operations.

Polypropylene: It has low density, light weight, good chemical stability, and is resistant to acid and alkali corrosion, but its strength is relatively low; it is not resistant to high temperature, and it is not suitable for lifting operations in high temperature environments.

High-strength high-modulus polyethylene fiber: lightweight, extremely high strength, more than ten times the strength of steel with the same cross-section, and wear-resistant and corrosion-resistant, it is widely used in some lifting scenarios with high weight and strength requirements.

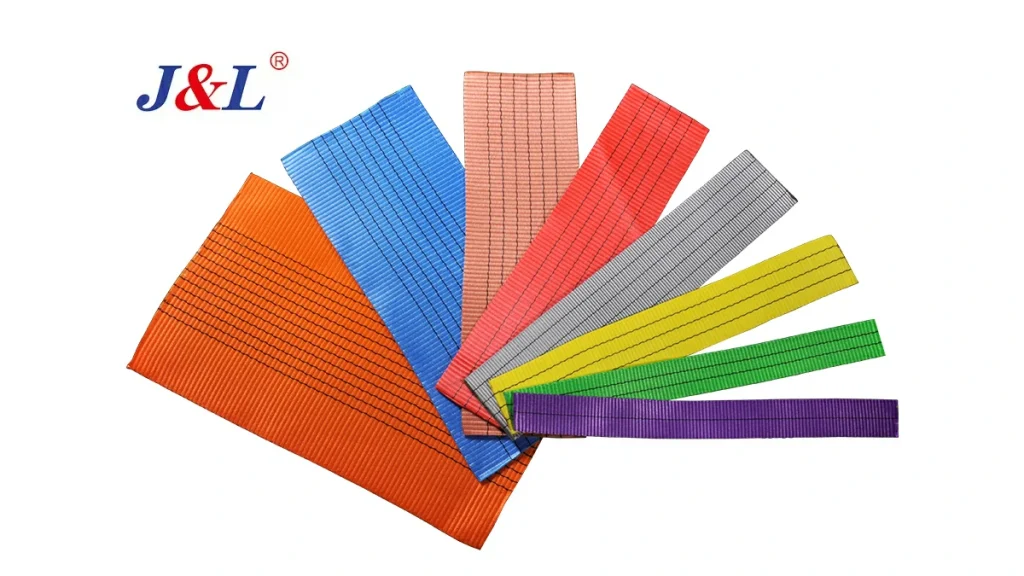

Synthetic slings usually come in many forms, such as synthetic fiber lifting belts (including annular core, annular flat, double-eye core, double-eye flat lifting belt, etc.), round lifting ropes, etc. Compared with traditional wire rope slings, synthetic slings have the advantages of light lightweight, soft, and easy to operate, no damage to the surface of the hoisted object, and no rust; but they also have disadvantages such as not being resistant to high temperatures and easy to be corroded by chemical substances.

Reasons why synthetic slings cannot be used on forklift forks

Easily damaged slings

The edges of forklift forks are usually sharp, and the surface may be uneven. When synthetic slings are put on the forks, under the pressure of lifting heavy objects, the sharp edges and rough surfaces of the forks will cause greater friction and compression with the slings, which can easily cause cuts and wear on the slings. The B30.9 standard of the American National Standards Institute (ANSI) clearly states that slings should avoid contact with sharp edges to prevent damage to the sling structure and reduce its rated load capacity. Once the synthetic sling is damaged, the load-bearing capacity will be greatly reduced, and it may break during the lifting process, causing heavy objects to fall.

Difficult to control the load

Forklift forks are not designed for lifting. Putting synthetic slings on forks cannot accurately and stably control the load like regular lifting equipment. In the process of lifting, moving, and lowering the load, the load is prone to shaking, tilting, or even flipping, which may not only cause damage to the cargo, but also pose a serious threat to surrounding personnel and equipment.

No safety standards and specifications: At present, there are no safety operating standards and specifications for the use of synthetic slings on forklift forks, either internationally or domestically. The lack of standards means that it is difficult to ensure the safety and standardization of operations in actual operations. Once an accident occurs, it will be difficult to define and deal with the responsibilities.

Safety violation

Occupational safety and health regulations in many countries and regions, as well as internal safety operating procedures of enterprises, prohibit the use of this unconventional and dangerous lifting method. For example, the Occupational Safety and Health Administration (OSHA) in the United States requires employers to ensure that the appropriate equipment and correct operating methods are used for lifting operations to ensure the safety of employees. Using synthetic slings on forklift forks obviously does not meet the safety operation requirements and is a violation.

So, what’s the right solution?

High-quality, purpose-built slings are the answer. This is where Juli Sling comes in. Our webbing slings, such as the popular Eye Type Webbing Sling and Endless Webbing Sling, are designed with safety and performance in mind.

Our Eye Type Webbing Slings feature loops at each end, making them easy to attach securely to lifting hooks and other rigging points. They’re perfect for general lifting tasks in construction, logistics, and manufacturing. With a wide range of load capacities and lengths available, you can find the exact sling to fit your needs.

If you need to lift delicate or fragile loads, our round slings are the ideal choice. Encased in a durable cover, these slings provide excellent abrasion resistance while protecting your precious cargo from damage.

At Juli Sling, we understand that safety is non – non-negotiable. That’s why all our synthetic slings, including webbing slings and round slings, are made from premium synthetic fibers. They are not only strong and durable but also compliant with strict international safety certifications like ISO. We also offer customization options, so you can get a sling that’s tailored to your specific lifting requirements, whether it’s a particular length, width, or load capacity.

Conclusion

In order to ensure the safety and smooth progress of lifting operations, special lifting equipment and tools that meet the standards should be used and operated in strict accordance with the operating procedures. If a forklift is required for lifting operations, it should be equipped with special lifting equipment suitable for the forklift. Choose safety and reliability with Juli Sling’s high-quality webbing slings and round slings. If you have any questions or need customized solutions for your lifting operations, don’t hesitate to contact us. Let us help you find the perfect synthetic slings for your business.