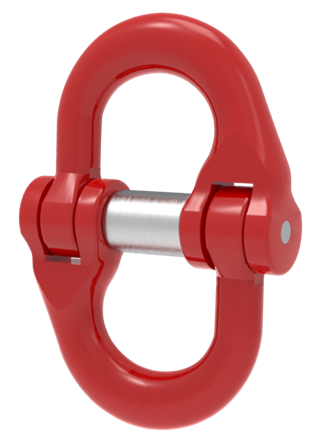

G80, G63 Connecting Link

Description

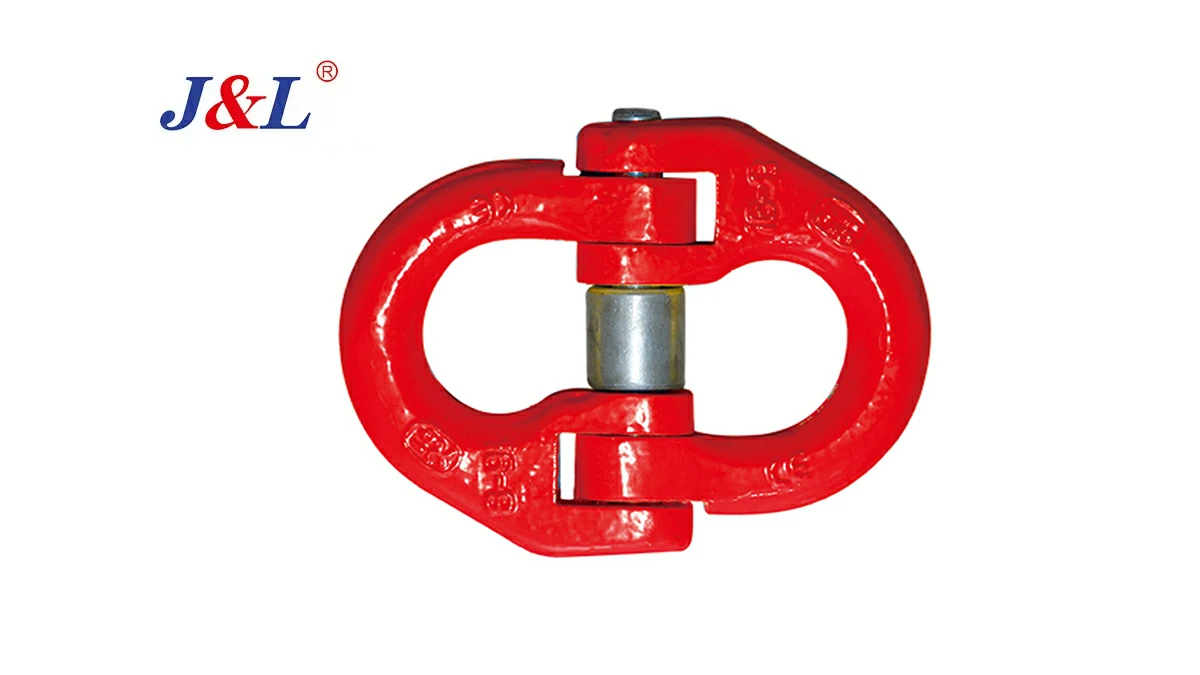

1. Product category: G63, G80 Connecting Link.

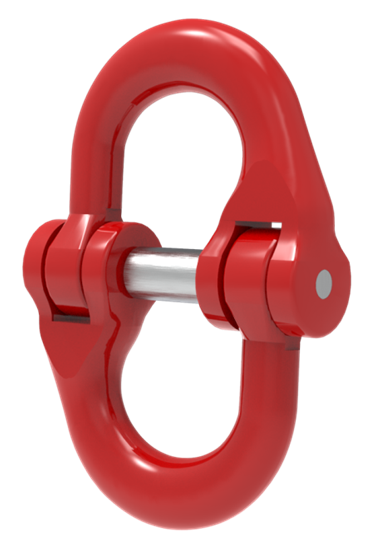

2. Adopt high-quality structural alloy steel and throughout swaged forging process.

3. Proof load is twice of the Working Load Limit. Minimum Ultimate Load is 4 times of the Working Load Limit.

4. Heat treatment.

5. There are signs such as Working Load Limit marked on the link.

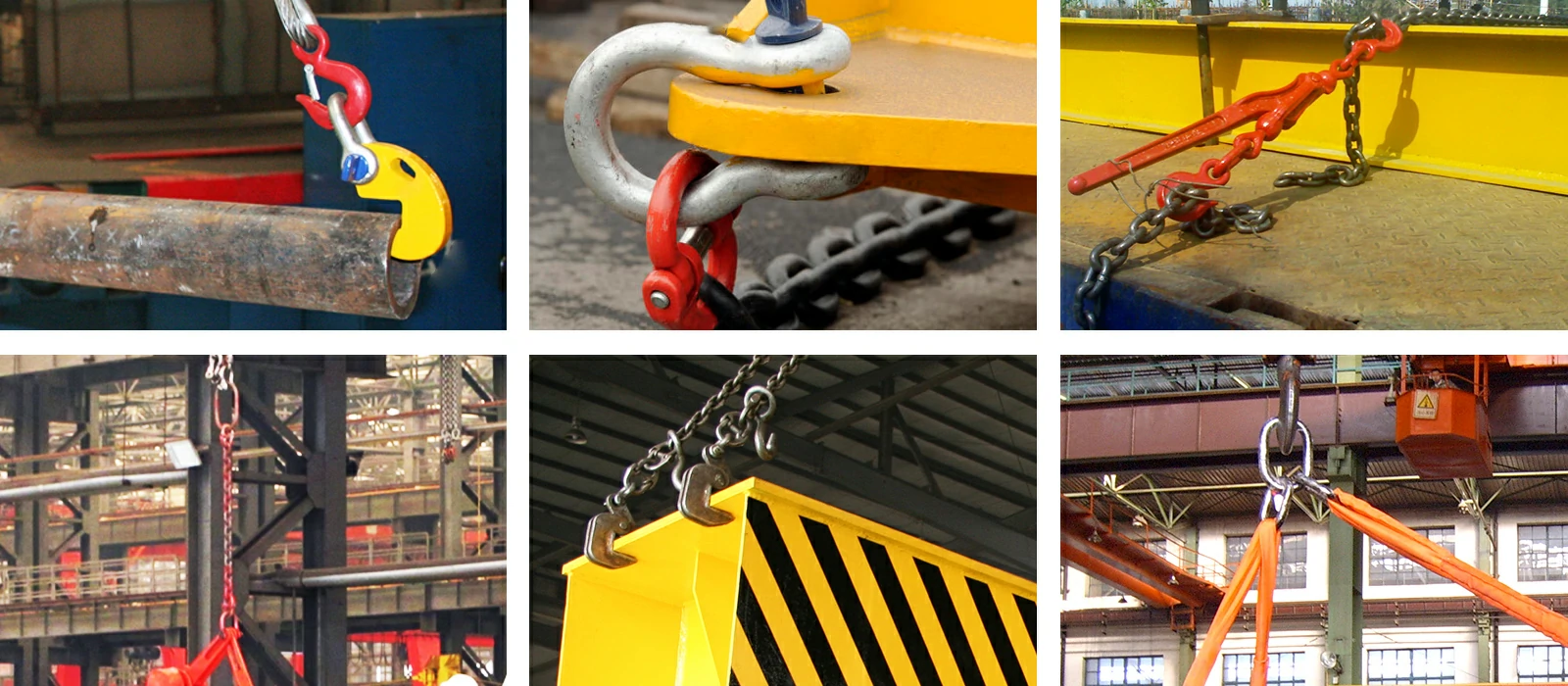

6. Used with chain, simply and firmly.

7. Specifications: With full range of product specification, working capacity: 1.5t-31.5t, can meet different hoisting requirements with various types.

8. Usage: Used as connection between the slings or between the sling and the suspended in the lifting, bunding, draging and fastening operation.

Features

Manufacture with prescision drop forging, heat treatment and surface treatment process. With full range of product specification, working capacity:1.5t - 31.5t, we can meet different hoisting requirements with various types.

Usage

Product use: Used as connection between the slings or between the sling and the suspended in the lifting, bunding, draging and fastening opearation.

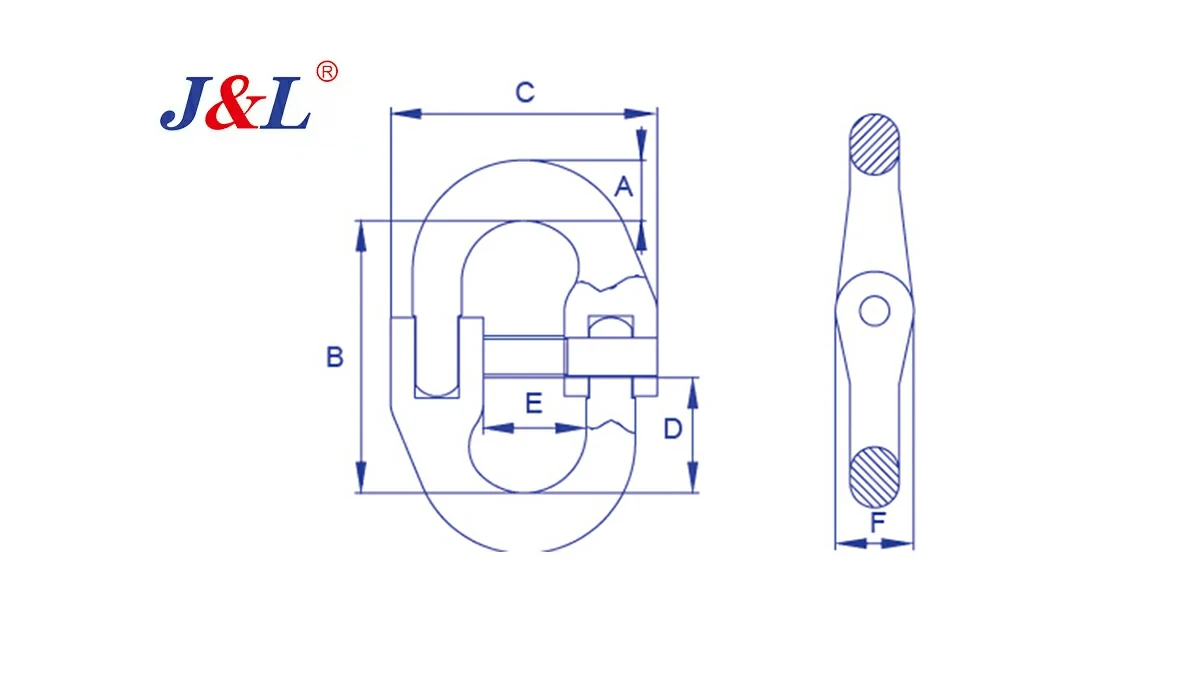

Specifications

| G80 Connecting Link | ||||||||||

|

Chain Size | Working load limit (t) | Dimensions (mm) | Self Weight (kg) | ||||||

| (In) | (mm) | A | B | C | D | E | F | |||

| 9/32(1/4) | 7 | 1.5 | 8.4 | 47.8 | 47 | 19.8 | 16 | 14.2 | 0.13 | |

| 5/16 | 8 | 2 | 9.15 | 55.4 | 50 | 23.1 | 16.8 | 16 | 0.15 | |

| 3/8 | 10 | 3.15 | 11.4 | 64.3 | 63.5 | 26.2 | 21.6 | 19.1 | 0.34 | |

| 1/2 | 13 | 5.3 | 16.3 | 87.4 | 81.8 | 36.6 | 27.7 | 23.9 | 0.75 | |

| 5/8 | 16 | 8 | 19.1 | 105 | 96 | 43.9 | 35.1 | 28.7 | 1.3 | |

| 3/4 | 20 | 11.2 | 23.6 | 126 | 118 | 53.1 | 40.4 | 32.5 | 2.26 | |

| 7/8 | 22 | 15 | 26.9 | 140 | 143 | 58.7 | 50 | 36.6 | 3.41 | |

| 1 | 25 | 21.2 | 31 | 152 | 157 | 63.5 | 56.4 | 47.8 | 5 | |

| 1-1/4 | 32 | 31.5 | 38.1 | 189 | 194 | 78.5 | 64.3 | 55.6 | 9.25 | |

| G63 Connecting Link | ||||||||||

|

Art. No. | d

(mm) |

Working load limit (t) | A

(mm) |

B

(mm) |

C

(mm) |

D

(mm) |

E

(mm) |

F

(mm) |

Self Weight (kg) |

| HDH12 | 12 | 3.5 | 17.5 | 94 | 37 | 13.5 | 88 | 20 | 0.67 | |

| HDH14 | 14 | 5 | 20 | 106 | 41 | 16 | 98 | 24 | 1.13 | |

| HDH16 | 16 | 6 | 23 | 114 | 45 | 18 | 110 | 27 | 1.61 | |

| HDH18 | 18 | 8 | 25 | 124 | 48 | 20 | 120 | 31 | 2.06 | |

| HDH20 | 20 | 10 | 28 | 131 | 50 | 23 | 130 | 34 | 2.73 | |

| HDH22 | 22 | 12 | 30 | 138 | 53 | 25 | 140 | 38 | 3.63 | |

| HDH24 | 24 | 14 | 33 | 150 | 59 | 27 | 152 | 42 | 4.73 | |

| HDH26 | 26 | 17 | 37 | 166 | 63 | 30 | 164 | 45 | 5.93 | |

| HDH30 | 30 | 22 | 40 | 180 | 65 | 33 | 170 | 50 | 7.14 | |

| HDH34 | 34 | 29 | 42 | 198 | 73 | 34 | 200 | 62 | 10.4 | |

Package

JULI standard export package: Packing bag and Carton, Customized packaging according to customer needs.

Certification

CNAS ISO

Technological Process

Manufacture with prescision drop forging, heat treatment and surface treatment process

The hook body is manufactured with high-quality alloy steel by die forging, heat treatment.

There are signs such as WORKING LOAD LIMIT and product grade on the link.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.