HLB Type Spreader Beam

HLB Type Spreader Beam – Adjustable, High-Performance Lifting Solution

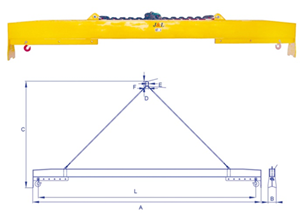

The HLB Type Spreader Beam from JULI Slings is engineered for versatile, precise, and safe lifting across a wide range of industrial applications. Designed with an L-type streamlined structure and equipped with durable lifting accessories, this spreader beam provides outstanding stability and adaptability when handling loads of different sizes and shapes.

Structural Design & Key Components

The HLB Type Spreader Beam features:

-

L-Type Streamlined Structure: Ensures uniform force distribution and reduces bending stress during lifting.

-

Premium Accessories: Includes high-strength pins, chain slings, and eye hooks (or swivel hooks) for secure, flexible connection.

-

Adjustable Hook Position: Operators can reposition the hooks based on load dimensions, allowing precise alignment and safer lifting.

For more lifting solutions, explore our hoisting beam options.

Advantages for Industrial Lifting

-

Highly Adaptable: Suitable for lifting wide or asymmetrical loads due to its adjustable hook system.

-

Enhanced Operational Safety: The streamlined form and balanced force distribution reduce the risk of load swing or instability.

-

Built for Heavy-Duty Use: Manufactured with high-strength steel and subjected to strict quality control to withstand demanding working conditions.

-

Fast Rigging Adjustment: Ideal for repetitive lifting tasks where quick configuration is essential.

Applications Across Industries

The HLB Type Spreader Beam is widely used in:

-

Construction & Engineering: Lifting beams, concrete blocks, machinery, and prefabricated components.

-

Shipbuilding & Marine: Handling ship sections, steel structures, and large fabricated parts.

-

Logistics & Warehousing: Efficient movement of bulky goods with stable load control.

-

Manufacturing Plants: Suitable for positioning large assemblies with precision.

As a global lifting equipment manufacturer, Juli sling provides custom solutions, enabling clients to specify beam length, hook spacing, sling type, and load capacity according to project requirements.

Specifications

| HLB TYPE BEAM | ||||||||

|

WLL (t) |

Dimension L(m) | Effective length (m) | Dimension of the master link ( mm ) | A×B×C (mm) | Self weight (kg) | ||

| D | E | F | ||||||

| 2 | 1~3 | 3 | 80 | 20 | 150 | 3180×160×1800 | 150 | |

| 3.2 | 3~5 | 5 | 90 | 24 | 160 | 5200×210×2100 | 350 | |

| 5 | 3~5 | 5 | 100 | 28 | 190 | 5300×240×2400 | 430 | |

| 8 | 6~8 | 8 | 110 | 32 | 200 | 8350×250×3800 | 720 | |

| 10 | 6~8 | 8 | 120 | 34 | 230 | 8350×280×3850 | 810 | |

| 12.5 | 6~8 | 8 | 135 | 38 | 250 | 8350×280×3900 | 945 | |

| 16 | 6~8 | 8 | 140 | 42 | 270 | 8350×300×4050 | 1170 | |

| 20 | 6~8 | 8 | 160 | 46 | 310 | 8400×300×4150 | 1475 | |

| 25 | 6~8 | 8 | 180 | 52 | 330 | 8460×380×4300 | 1585 | |

| 32 | 6~10 | 10 | 180 | 56 | 330 | 10500×480×4550 | 2720 | |

| 40 | 6~10 | 10 | 220 | 69 | 396 | 10500×480×4650 | 2790 | |

| 1.Structure: I type and streamline form. | ||||||||

| 2.Accessories: pin, chain sling, eye hook . | ||||||||

| 3.Function and characteristic: adjust the position of the hook per the dimensions of the loads. | ||||||||

FAQ

Q1: Are you a factory or a company?

Juli Sling is an OEM/ODM manufacturer with nearly 38 years of history.

We specialize in the R&D and production of rigging.

Q2: What are your delivery terms?

We accept EXW, FOB, CIF, etc. If you have other options or requirements, we can negotiate to find the most convenient and cost-effective solution for you.

Q3: How does your factory conduct quality control?

Quality is paramount. We always attach great importance to quality control. Skilled workers pay attention to every detail in the production process, and each step undergoes rigorous quality inspection. We can provide customers with authoritative inspection reports.

Q4: What payment methods are available?

We accept T/T and L/C payments. Other payment methods are negotiable.