How to Calculate Wire Rope Sling Capacity

June 9, 2025

1. Introduction: The Unseen Strength of Wire Rope Slings

Wire rope slings are vital tools in heavy industries like marine operations, mining, the oil and gas, construction, manufacturing, and logistics, etc. They’re crucial for lifting and securing massive loads, performing reliably due to their strength, durability, and resistance to heat and abrasion.

However, safe use demands professional knowledge of the lifting capacity. Safety knows no trifles; sling failures lead to serious safety risks—equipment breakdowns, dropped loads, severe injuries, and even fatalities. This guide offers an expert approach to mastering these calculations, ensuring your lifting operations meet the highest safety standards and comply with regulations from bodies like OSHA, ASME, and EN standards.

2. Why Accurate Sling Capacity Calculation is Significant?

Precise sling capacity calculation is fundamental to operational integrity, directly impacting safety, regulatory compliance, and your bottom line. Knowing the true capacity of the sling is essential to prevent overloading and avoid accidents, to minimize equipment damage and costly downtime, and to achieve smooth, predictable lifting.

Overloading gains the risks of sudden failure, injuries, and fatalities. Beyond human cost, failures lead to significant financial losses. Accurate capacity calculations are your primary defense. Adhering to industry standards (OSHA, ASME, EN 13414-1) is a legal and ethical imperative, ensuring consistent safety. Proper calculation and adherence to WLL also prevent premature wear, extending sling lifespan and improving your return on investment .

3. Understanding Wire Rope Slings: Construction and Core Differences

A solid grasp of wire rope sling construction and core types is vital for accurate capacity determination and safe application.

3.1. Construction (e.g., 6×19, 6×36, 7×19)

Wire rope construction dictates its flexibility, strength, and resistance to abrasion or fatigue.

| Wire rope class | Characteristics |

| 6×19 Class | Owning excellent abrasion resistance and high strength, suitable for general lifting. |

| 6×36 Class | With enhanced flexibility and fatigue resistance, ideal for dynamic environments like cranes |

| 7×19 Class | With superior flexibility, best for applications requiring frequent bending |

3.2. The Role of the Core: Fiber Core vs. Independent Wire Rope Core

The core supports the strands and maintains rope shape, affecting strength, durability, and environmental resistance.

FC offers greater flexibility and shock absorption, suitable for lighter loads and frequent bending. Less tensile strength, prone to crushing, and unsuitable for high heat (above 180℉/82℃).

IWRC provides superior strength, rigidity, and excellent resistance to crushing and high temperatures. IWRC adds about 7.5% to the main rope’s strength.

The choice depends on load capacity, flexibility needs, and environmental conditions.

3.3. Common Sling Configurations: Vertical, Choker, Basket, and Multi-Leg Bridles

How a sling is used dramatically alters its effective lifting capacity.

- Vertical lifting: Direct pull, uses full rated WLL.

- Choker Hitch: Sling wraps around load, reducing capacity by 20-25% (the angle is less than 120°). Choke point must be on the sling body.

- Basket Hitch: Sling passes under load, both eyes to hook. It can potentially double capacity if legs are vertical and D/d ratio is favorable. The load must be balanced.

- Multi-Leg Bridle Slings: Used for multiple attachment points. Load is distributed, but the angle of the legs is critical; as legs become flatter, tension on each leg increases dramatically, reducing overall capacity. Always use the smallest horizontal angle for calculation.

4. Key Factors Influencing Wire Rope Sling Capacity

Beyond the label, several factors dynamically alter a sling’s true lifting capability: Rope Diameter, Sling Angle, Sling Configuration, Sling Material & Construction, and Safety Factor.

4.1. MBL and WLL

The MBL is the minimum force a new wire rope withstands before breaking, provided by the manufacturer. The WLL is the maximum safe load. WLL is derived from MBL by applying a Safety Factor.

For general lifting, the standard SF is typically 5:1 in US and EN standards (WLL is 20% of MBL). Higher SFs (e.g., 10:1) are required for personnel lifting.

WLL= Safety Factor/MBL

4.2. The Critical Impact of Sling Angle

The sling angle profoundly impacts effective lifting capacity. As the angle between sling legs and the horizontal decreases, tension on each leg increases significantly, reducing overall capacity. A 30° horizontal angle effectively halves capacity.

If the angle is measured from the horizontal, the Angle Factor is sin.

Adjusted WLL =WLL (Vertical)×Angle Factor

Horizontal angles less than 30° are generally unsafe. Both US and EN standards provide guidelines for angle adjustment.

4.3. Diameter of Curvature (D/d Ratio):

The D/d Ratio compares the diameter of the object the sling bends around (D) to the rope’s diameter (d). Bending a rope around too small a diameter increases stress and fatigue, significantly reducing capacity (e.g., D/d = 1:1 can reduce strength by 50%).

Recommended minimum D/d ratios: Mechanically Spliced: 25:1; Hand Spliced: 15:1; Braided Multi-Part: 25:1. Always use thimbles in sling eyes and protect slings with softeners or blocking at sharp corners.

4.4. Sling Type and Fabrication Efficiency

The capacity is also influenced by its type (e.g., single-part, braided, grommet) and fabrication method. Braided slings offer higher capacity and flexibility. Grommets provide extra capacity. Always refer to the manufacturer’s specified rated load, as it accounts for these factors.

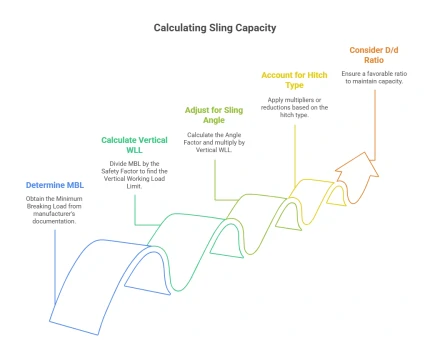

5. Step-by-Step Sling Capacity Calculation

Example: For a 1-inch IWRC sling (MBL 25,000 lbs), SF 5, at a 60° horizontal angle, the Adjusted WLL is approximately 4,330 lbs.

6. Essential Safety Practices and Sling Management

6.1. Pre-Use and Periodic Inspections

A competent person must visually inspect slings daily before use. Periodic inspections are also required: yearly for normal service, monthly to quarterly for severe service. Look for: missing/illegible ID tag, broken wires (specific limits apply), severe abrasion, kinking, crushing, bird-caging, heat damage, cracked/deformed/worn end attachments, severe corrosion, diameter reduction (>5%), or excessive waviness (>110%). Always remove damaged slings immediately.

6.2. Criteria for Removal from Service

Any damaged or defective sling must be immediately removed from service. It cannot be returned until approved by a qualified person after repairs. Wire rope itself cannot be repaired; only end attachments/fittings can be reconditioned, and repaired slings must be marked. Using damaged slings, even if they “seem” sufficient, is a non-negotiable safety violation.

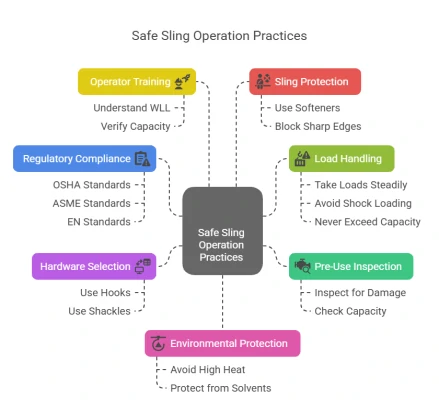

6.3. Best Practices for Safe Operation

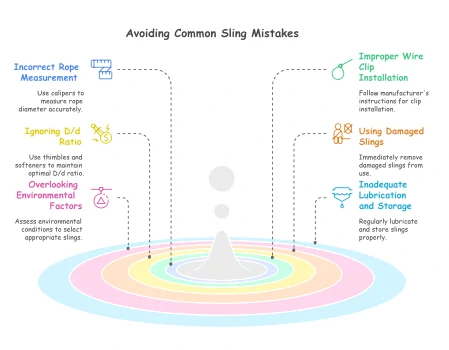

7. Common Mistakes and How to Avoid Them

8. Conclusion: Elevating Safety and Performance Through Knowledge

Mastering sling capacity calculation and adhering to safety protocols are fundamental for safe, compliant, and efficient lifting operations. Understanding sling construction, core types, and hitch configurations is crucial for informed decisions. Proactive sling management—inspections, strict removal criteria, and safe operating practices—forms a robust defense against accidents. Avoiding common mistakes further reinforces safety. Integrating this knowledge elevates safety culture, ensures compliance, and optimizes performance.

At Juli Sling Co., Ltd., we are deeply committed to safety and possess extensive expertise in industrial lifting solutions. We provide not just high-quality equipment, but also the authoritative knowledge essential for uncompromised operational integrity. Contact Juli to ensure your safe lifting operations for peak performance.