Juli Henan Wire Rope Plant Doubles Capacity to 80,000 Tons for Global Infrastructure Boom

July 4, 2025

Juli branch factory, Henan Wire Rope Plant, has completed a $50 million (RMB 350M) facility expansion, increasing annual production capacity to 80,000 tons of premium steel cable wire and steel strand. The new 150,000㎡ complex features automated production lines for critical infrastructure materials.

The production line covers galvanized steel wire,steel strand and steel wire for bridge cables.

- Bridge cable steel wire : It is a high-performance load-bearing cable system designed for large bridges. Permanent main bearing structure ( design life ≥ 100 years ). It plays an important role in bridge construction, power engineering and other fields.

- Prestressed steel strand : single-layer or multi-layer steel wire spiral wound ( no independent rope core ). For static tension, permanent fixation. The product is widely used in the prestressed structure of wind power generation and construction engineering to provide stable support for the building.

Representative Projects: Showcasing Our Products in Action

Xiangtan Bridge in Hunan Province is the world ‘s first cable-stayed steel pipe arch bridge. The bridge spans three rivers.

The Hong Kong-Zhuhai-Macao Bridge is the first super-large cross-sea channel jointly built by Guangdong, Hong Kong and Macao. The total length is 55 KM. Our company has undertaken the production of high-strength anchors for the main tower of the bridge, the installation and construction of stay cables, and the design and production of bridge deck and main tower slings.

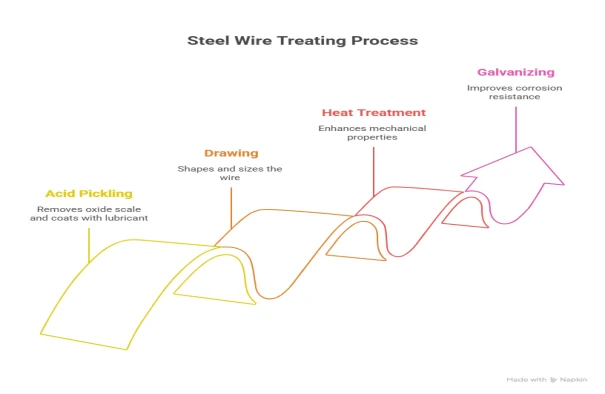

Wire Treatment Process: Enhancing Strength and Durability

- Acid Pickling :This process effectively removes the oxide scale from the surface of the wire rod and applies a lubricating coating to enhance performance.

- Drawing : Obtain the required cross section shape and size, and improve the comprehensive mechanical properties of steel wire.

- Heat Treatment: The heat treatment production line at Juli represents the world’s most advanced continuous production system for steel wire heat treatment, capable of handling the largest wire diameters. Utilizing environmentally friendly natural gas combustion as the heating source, the process ensures that the steel wire is protected by nitrogen throughout the heating phase. This protection maintains a completely non-oxidized state during production, thereby ensuring optimal mechanical properties and surface quality of the steel wire.

Galvanizing: This process enhances the anti-corrosion properties of the wire. The vertical hot-dip galvanized steel wire can achieve a zinc coating of over 300 g/m², which fully supports the production of large-diameter, high-strength galvanized steel wire. Additionally, the retractable line for steel wire operates similarly to the heat treatment process, allowing the steel wire to be produced in a mode that accommodates large plate weights.

Future Outlook: Elevating Production and Sustainable Growth

The successful implementation of the second phase project of Juli Henan Wire Rope Plant marks that the company ‘s production capacity, technology and industrial chain integration ability in the field of high-end wire rope have reached a new level.

With excellent products and services, we help our customers to succeed, and realize the sustainable development of the enterprise.

If you need steel wire ropes, please feel free to contact us at any time!