Lashing Belt Material

Feature of Lashing Belt Material

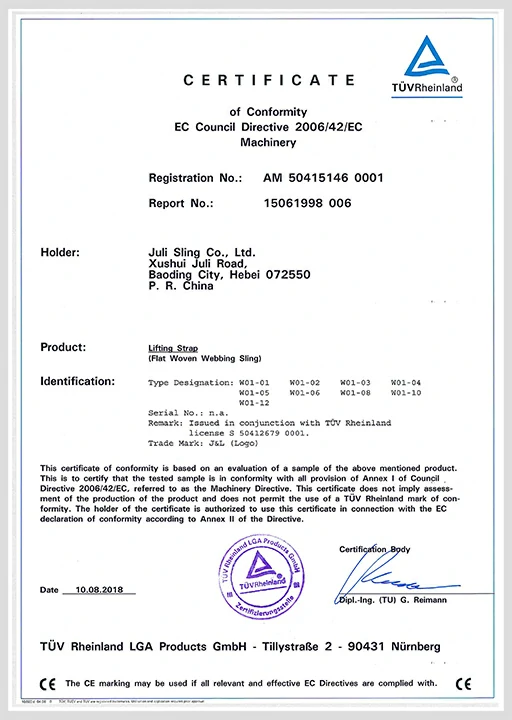

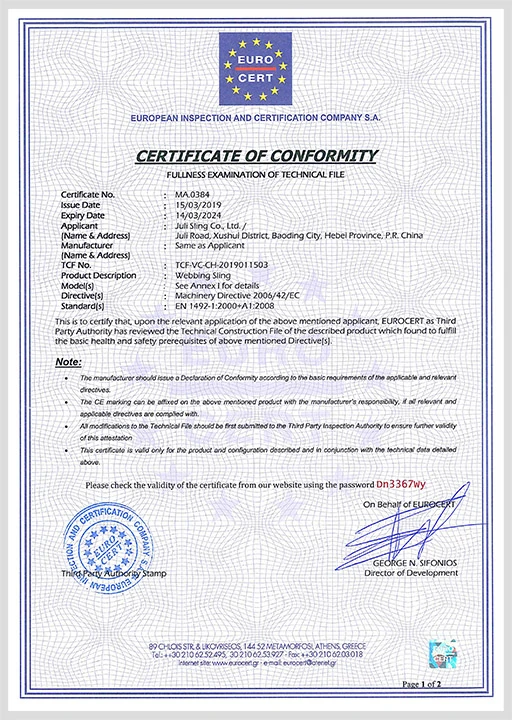

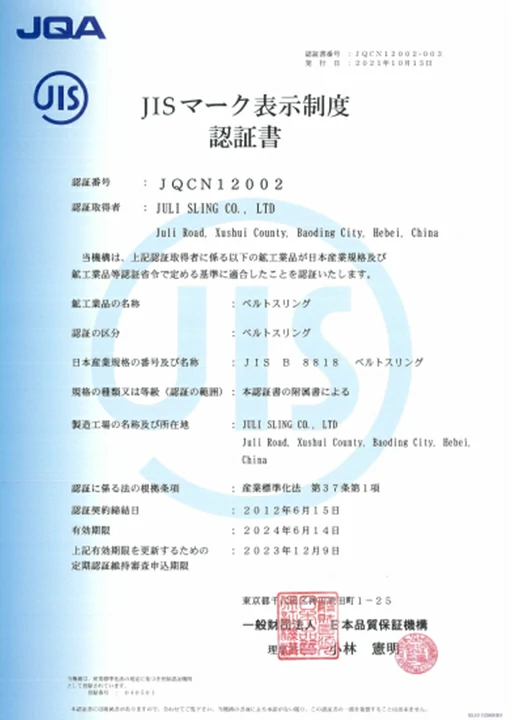

High quality: Strict quality control. Authoritative testing report can be provided.

Certifications: Perform with EN standard, American standard, Australian standard. Products with CE GS certifications.

Product Advantages: High-strength, anti- slip, wear- resistant, high temperature resistant, soft, light, no harm to the cargo, safety, long life, etc.

Our Advantages

Advanced Manufacturing Equipment: Switzerland Muller weaving machines, Germany dyeing machines, Japan automatic sewing machines, etc.

Production Capacity: Textile sling factory is the largest base for lifting belts, with the production capacity over 20,000t.

Well-experienced: Nearly 40 years of OEM&ODM manufacturing experience, supporting customized product.

Company strength: Covering a land area about 357,855㎡. With over 3,000 sales. The amount of exports exceeds USD 46,000,000 per year.

Applications

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

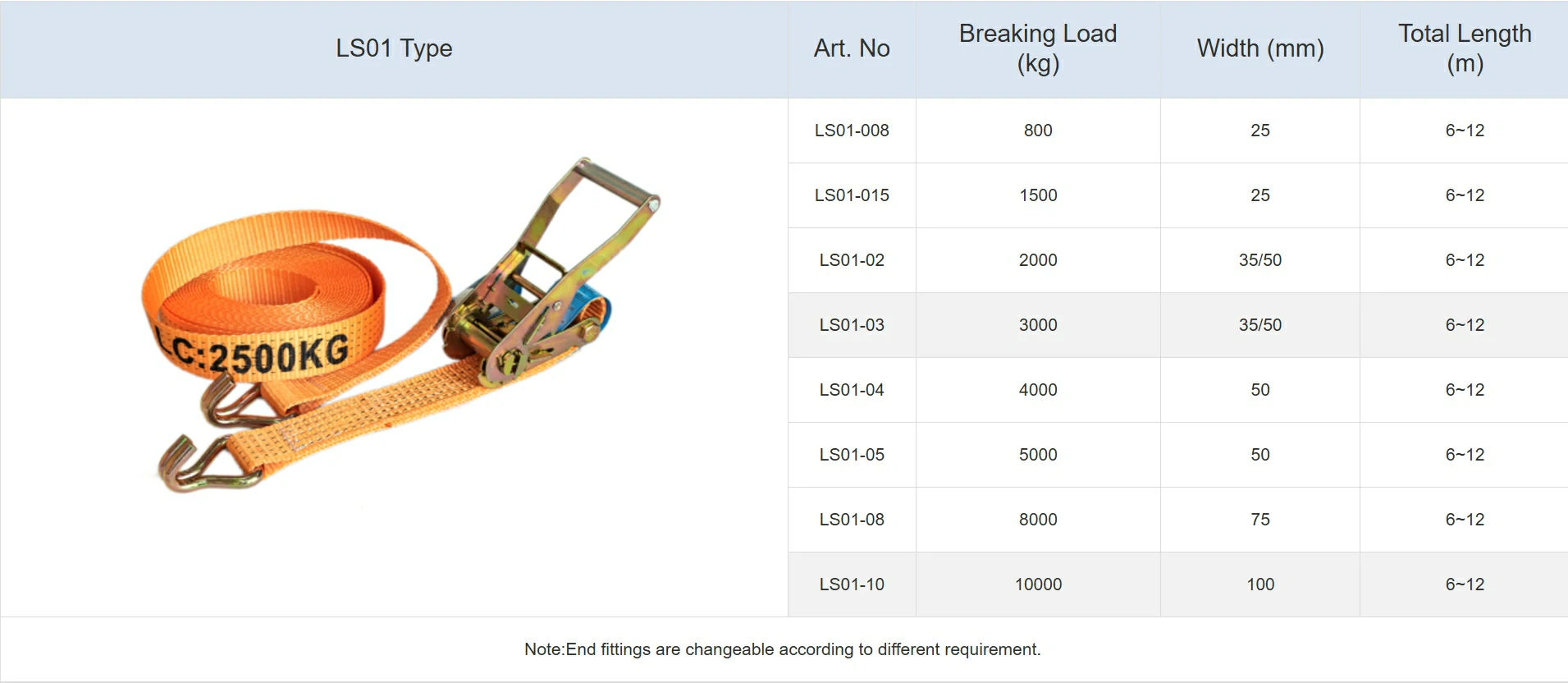

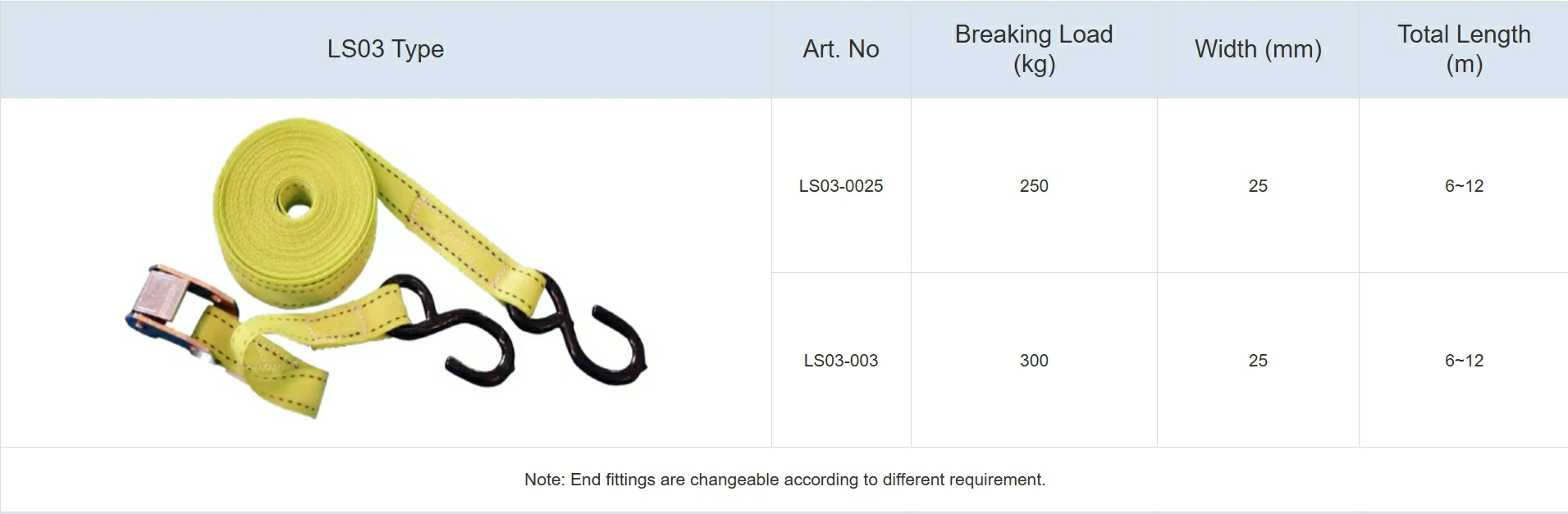

Specifications

1. Product Name: Lashing Belt Material

2. WLL: 1T~10T/Customized

3. Length: Customized

4. Color: Customized

5. Material: Polyester, Polypropylene, Nylon

6. Brand Name: J&L

7. Place of origin: Hebei, China

8. Provide OEM. ODM. : Yes

9. Standard: USA standard EN1492-1

10. Certification: CE, GS

11. Safety Factor: 2:1, 3:1

We can provide right solution for you. If you want to learn about more information, please contact us.

Package

JULI standard export package: Heat shrinking film packaging + Carton + Pallet

Customized packaging according to customer needs.

Certifications

JIS CE GS

Production Process

Production capacity: We can produce customised products for different applications and customer requirements.

Production process: Beam Warping—Weaving —Dyeing —Sewing —Clean & iron—Taping—Finished Products

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.