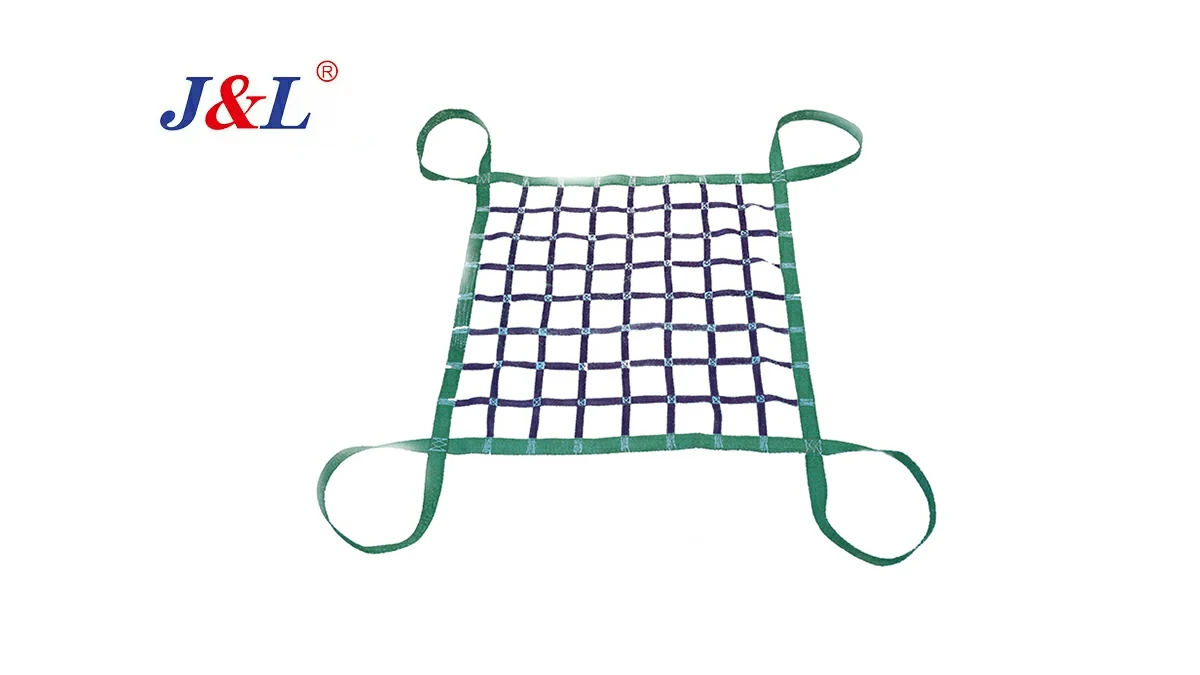

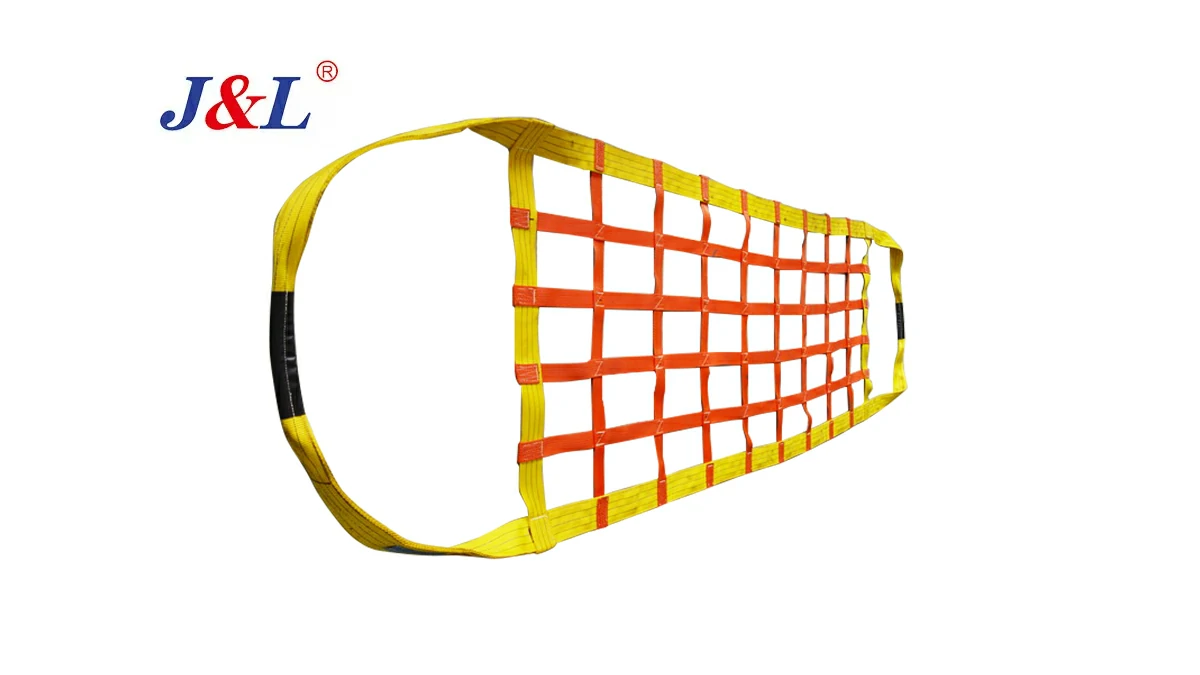

Lifting Net

Juli Cargo Lifting Net Description

1. Product Name: Lifting Net

2. Product Advantages: High-strength, anti- slip, wear- resistant, high temperature resistant, soft, light, no harm to the cargo, safety, long life, etc.

3. Material: Polyester, Polypropylene, Nylon

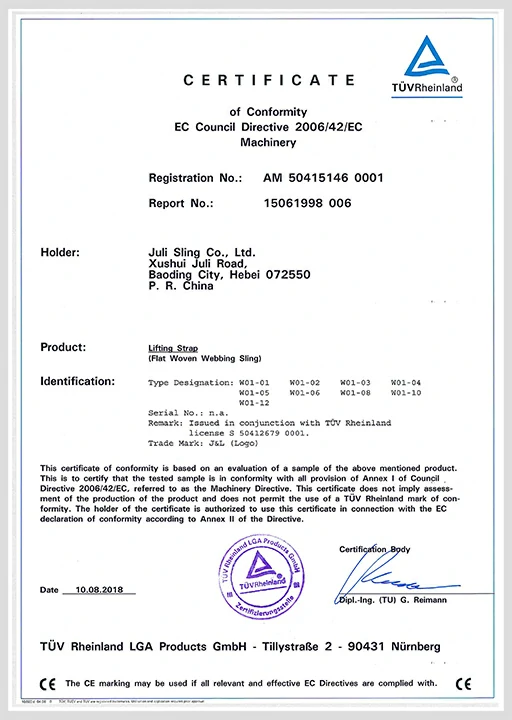

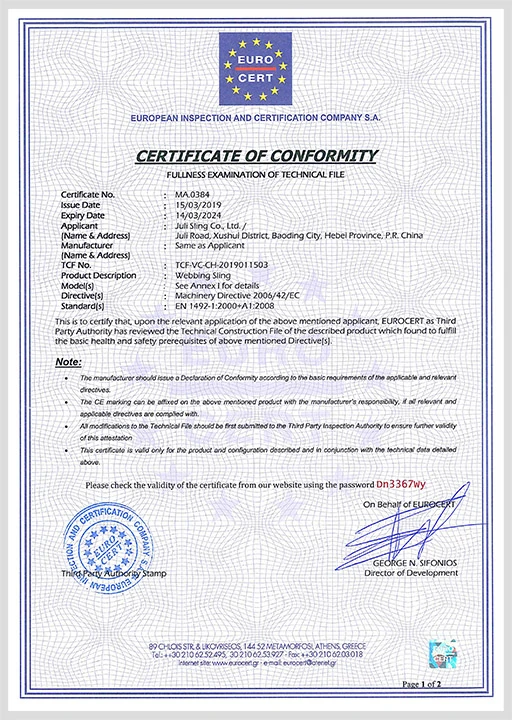

4. Standard: Standard EN1492-1:2000+A1:2008

5. Certifications: Perform with EN standard, American standard, Australian standard. Products with CE GS certifications.

6. High quality: Strict quality control, Authoritative testing report can be provided.

Juli Cargo Lifting Net Features

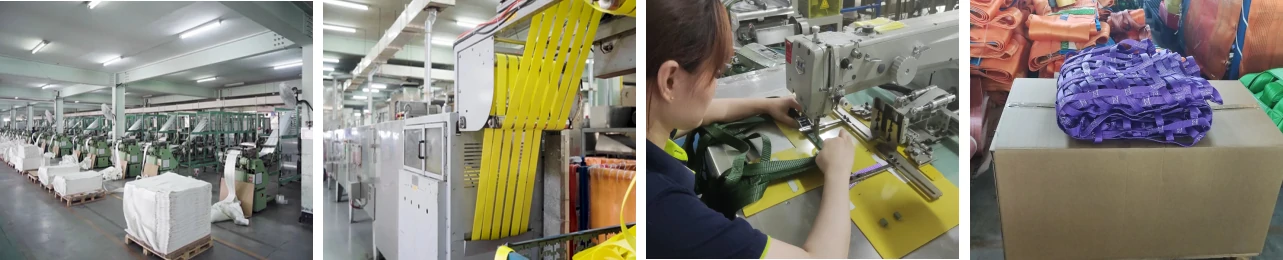

Advanced Manufacturing Equipment: Switzerland Muller weaving machines, Germany dyeing machines, Japan automatic sewing machines, etc.

Production Capacity: Textile sling factory is the largest base for lifting belts, with the production capacity over 20000t.

Well-experienced: Nearly 40 years of OEM&ODM manufacturing experience, Support customized product.

In recent years, julisling has obtained 222 authorized patents and over 2,200 implemented standards, edited and participated in 50 national, industrial and local standards, and won 95 provincial and municipal scientific and technological achievements, becoming the "Editor" of rigging industry standards.

Applications

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

Specifications

1. Product Name: Lifting Net

2. WLL: Customized

3. Length: Customized

4. Color: Customized

5. Material: Polyester, Polypropylene, Nylon

6. Brand Name: J&L

7. Place of origin: Hebei, China

8. Provide OEM. ODM. : Yes

9. Standard: Standard EN1492-1:2000+A1:2008

10. Certification: CE, GS, ISO

11. Package: Customized

We can also customized special products according to different hoisting requirement and customer demand.

| Type | |

| Lifting Net | |

| There are lifting net and protection net. And they are mainly used in construction,mining industry and daily life. The characteristics are flexible, strike-endurable. |

|

Extraordinary manufacturing excellence

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t. We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan, etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling. mooring ropeand traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE(high molecular weight polyethyienematerial). We are able to manufacture special slings such as high-strength type, flame retardanttype, antil - slip type, wear - resistant type, acid and alkall resistant type, high temperature resistanttype, fuorescent type, optical inspection type and oll and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage: Textile slings are widely used for lifting, pulling, bundling, fixed and otheroperations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

Package

JULI standard export package: Heat shrinking film packaging + Carton + Pallet

Customized packaging according to customer needs.

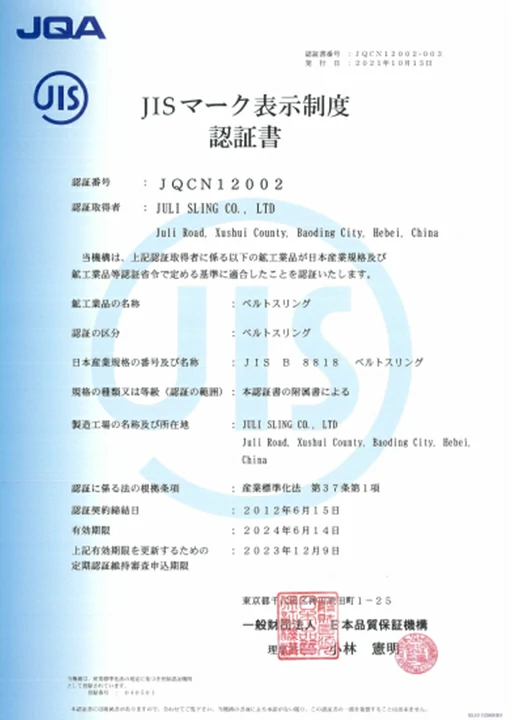

Certifications

JIS CE GS

Production Process

Production capacity: We can produce customised products for different applications and customer requirements.

Production process: Beam Warping—Weaving —Dyeing —Sewing —Clean & iron—Taping—Finished Products

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.