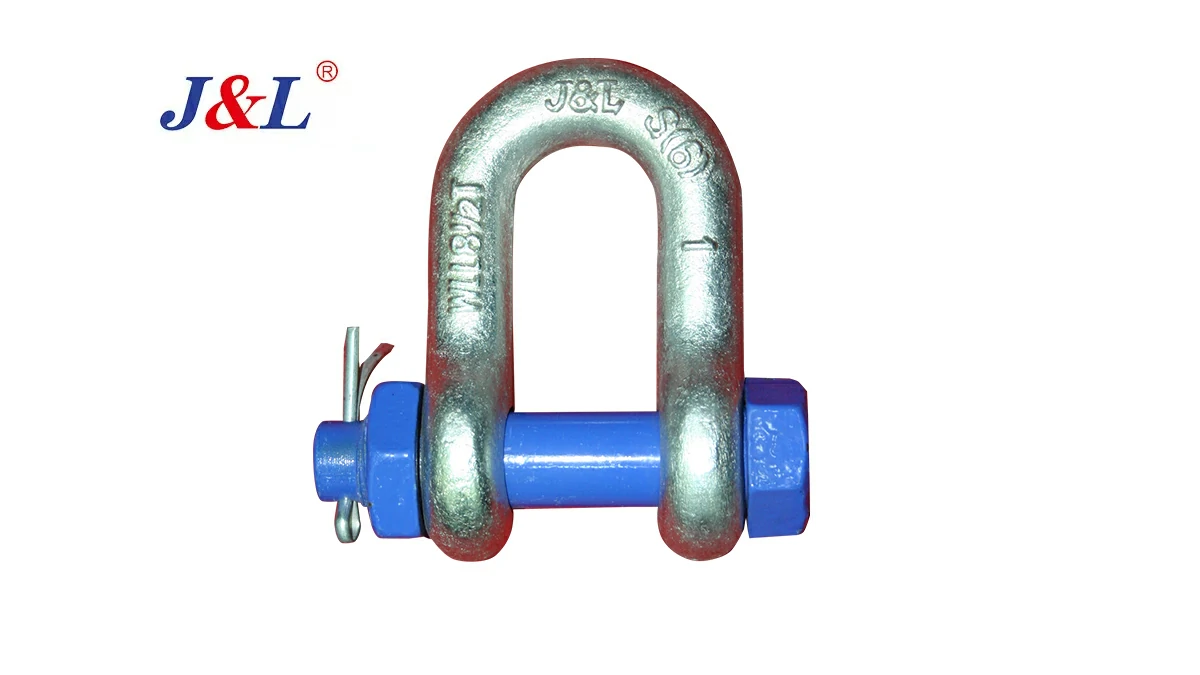

Grade S(6) D Shackle

D Shackle Description

1. The D shackles (both body and pin) we produce are made of high quality alloy steel through advanced production line and intermediate frequency furnace heat treatment.

2. Product category: Grade S6 D shackle.

3. Production range: 0.5t-85t.

4. The Maximum testing load is twice of the working load, the minimum breaking load is 6 times of the WLL

5. Our products all correspond with the stipulated technical requirement and test approach in standard ISO2415-2004.

6. Non-destructive flaw detection is employed for every single product to ensure there is no intensity defect.

D Shackle Features

The D shackles (both body and pin) we produce are made of high quality alloy steelthrough advanced production line and intermediate frequency furnace heat treatment. It is characterized by high-intensity, good toughness, small volume, light weight, beautiful appearance and good durability.

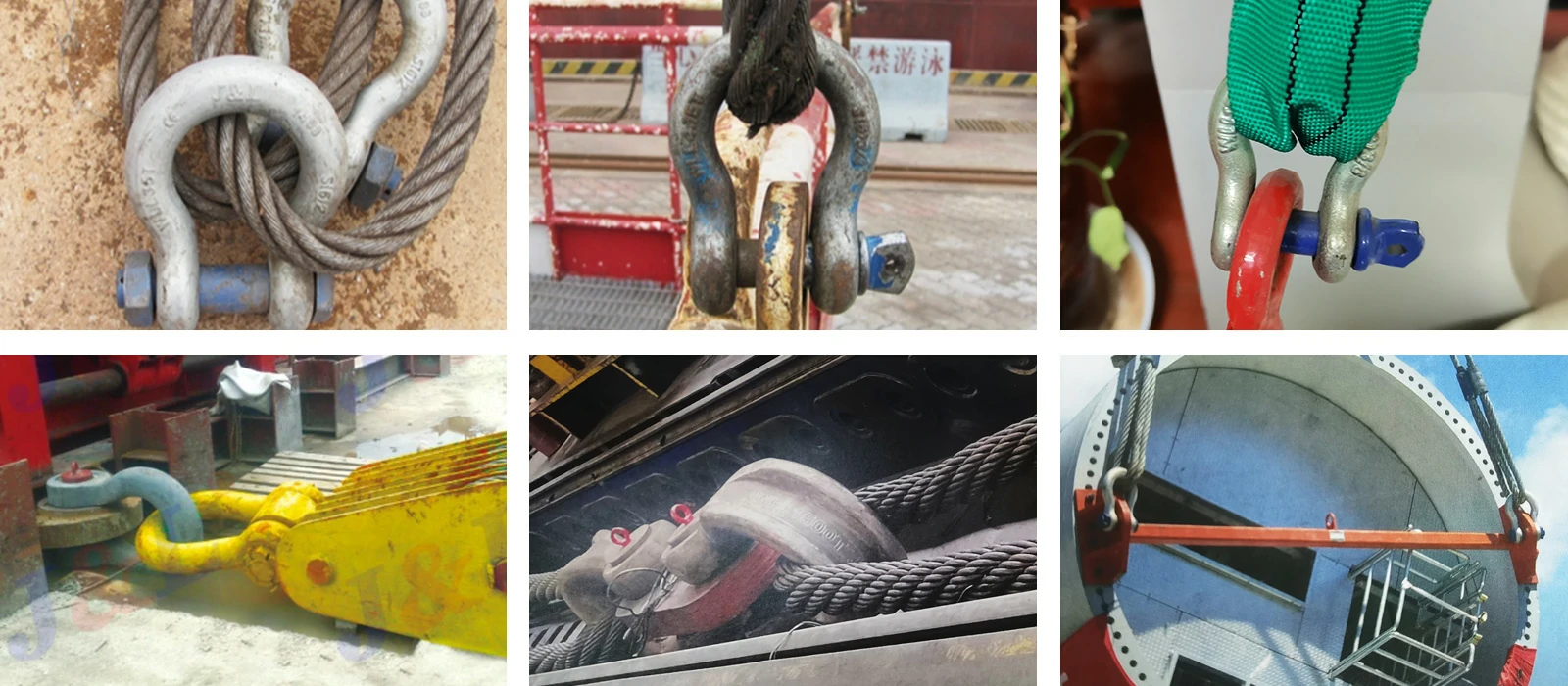

D Shackle Usage

No need to use the thimble when the bow shackle was connected with high-strength lifting belt, wire rope sling and large radius's domed roof. Wear-resisting property of the wire rope sling is improved obviously.

Specifications

At present D shackles used widely are made of alloy steel instead of carbon steel in the past. International standard D shackles include D shackles for lifting, D shackles for ship and ordinary D shackles. D Shackles with big weight and volume are usually installed where seldom disassembled. Safety factor (usually there are 4:1, 6:1 and 8:1 available) is an important point when choosing D shackles. We must use the shackles according to their WLL. Overuse and overload are both forbidden. D Shackles widely used in market include Chinese standard, American standard and Japanese standard. American standard D shackles are used more because of small volume and big capacity. According to different type, American standard D shackles include G209(BW), G210(DW), G2130(BX), G2150(DX); According to different using occasions, American standard D shackles include D shackles for ship and D shackles used on land. For safety factor, there are 4:1, 5:1, 6:1 and even 8:1. For the raw material, there are carbon steel, alloy steel, stainless steel, high-strengthl steel etc. For the treatment, there are galvanizing (include hot-dip galvanizing and electrogalvanizing).

| Grade S6 D Shackle | ||||||||||||

|

Art. No. | WLL (t) |

W (mm) |

D (mm) |

d (mm) |

E (mm) |

P (mm) |

S (mm) |

L (DW type) (mm) |

L (DX type) (mm) |

Self Weight (DW type) (kg) |

Self Weight (DX type) (kg) |

| S-DW0.5-1/4 S-DX0.5-1/4 |

0.5 | 12 | 8 | 6.5 | 15.5 | 6.5 | 22 | 36.5 | 37 | 0.04 | 0.06 | |

| S-DW0.75-5/16 S-DX0.75-5/16 |

0.75 | 13.5 | 10 | 8 | 19 | 8 | 26 | 44.5 | 45 | 0.08 | 0.1 | |

| S-DW1-3/8 S-DX1-3/8 |

1 | 17 | 12 | 9.5 | 23 | 9.5 | 32 | 52.5 | 54 | 0.13 | 0.13 | |

| S-DW1.5-7/16 S-DX1.5-7/16 |

1.5 | 19 | 14 | 11 | 27 | 11 | 36.5 | 62 | 62 | 0.2 | 0.21 | |

| S-DW2-1/2 S-DX2-1/2 |

2 | 20.5 | 16 | 13 | 30 | 13 | 41.5 | 70.5 | 71.5 | 0.27 | 0.28 | |

| S-DW3.25-5/8 S-DX3.25-5/8 |

3.25 | 27 | 20 | 16 | 38 | 16 | 51 | 88 | 89 | 0.57 | 0.6 | |

| S-DW4.75-3/4 S-DX4.75-3/4 |

4.75 | 32 | 22 | 19 | 46 | 20.5 | 60.5 | 102.5 | 105 | 0.99 | 1.04 | |

| S-DW6.5-7/8 S-DX6.5-7/8 |

6.5 | 36.5 | 27 | 22.5 | 53 | 24.5 | 71.5 | 121 | 121 | 1.57 | 1.63 | |

| S-DW8.5-1 S-DX8.5-1 |

8.5 | 43 | 30 | 25.5 | 60.5 | 25.5 | 81 | 139 | 136.5 | 2.3 | 2.38 | |

| S-DW9.5-1 1/8 S-DX9.5-1 1/8 |

9.5 | 46 | 33 | 29 | 68.5 | 32 | 91 | 153 | 149.5 | 3.42 | 3.59 | |

| S-DW12-1 1/4 S-DX12-1 1/4 |

12 | 51.5 | 36 | 32 | 76 | 35 | 100 | 168.5 | 164.5 | 4.48 | 4.65 | |

| S-DW13.5-1 3/8 S-DX13.5-1 3/8 |

13.5 | 57 | 39 | 35 | 84 | 38 | 111 | 184.5 | 179 | 6.46 | 6.71 | |

| S-DW17-1 1/2 S-DX17-1 1/2 |

17 | 60.5 | 42 | 38 | 92 | 41 | 122 | 199 | 194.5 | 7.65 | 8.05 | |

| S-DW25-1 3/4 S-DX25-1 3/4 |

25 | 73 | 52 | 44.5 | 106.5 | 54 | 146 | 244 | 239 | 12.48 | 13.18 | |

| S-DW35-2 S-DX35-2 |

35 | 82.5 | 60 | 51 | 122 | 61 | 171.5 | 275 | 269 | 18.63 | 19.3 | |

| S-DW55-2 1/2 S-DX55-2 1/2 |

55 | 105 | 72 | 66.5 | 144.5 | 66.5 | 203 | 346 | 344 | 36.02 | 37.22 | |

| 1. It is made of high quality alloy steel by die forging. | ||||||||||||

| 2. Each D shackle will be marked with WLL permanently, WLL from 0.5t ~ 85t. | ||||||||||||

| 3. The Maximum testing load is twice of the working load, the minimum breaking load is 6 times of the WLL. | ||||||||||||

Package

JULI standard export package: Poly Bag+Pallets, Customized packaging according to customer needs.

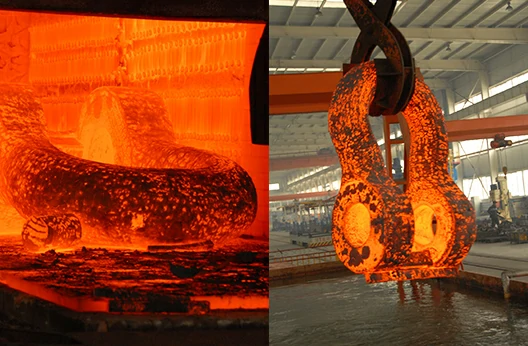

Technological Process

The forging rigging factory of Juli Sling Co.,Ltd is the largest production base for forging rigging in Asia with advanced forging, heat treatment, surface coating and nondestructive testing equipment and the most advanced production technology. Main forging equipment: 5T size free forging hydraulic hammer, 4,000t, 2,500t, 1,000t size friction press machine and 750kg ~ 1000kg size air forging hammer etc. We also researched and developed 400t, 1,000t, 1,500t, 2000t size bending machine. The annual producing capacity is 20,000t. Product category: Flat shackle, Large WLL shackle with circular cross-section, Bow shackle, D shackle etc.Production range: 0.5t-2,000t.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.