Spliced Steel Wire Rope Sling

Description

1. Spliced Steel Wire Rope Sling Process range: Up to 190mm

2. The specification of steel wire rope: 6mm-60mm

3. Product construction: 6×37 type b-1670

4. Breaking load: 5 times of the working load (The work load are shown in the table below)

5. Length: Customized

6. Provide OEM. ODM. : Yes

7. Brand Name: J&L

8. Place of origin: Hebei, China

9. Standard: API-9A

Different construction of the rope means different working load, we can calculate the working load according with the steel wire rope construction which the customer required.

Our Advantages

1. High performance cable sling is manufactured through special splicing process by JULl independently researched and produced professional equipment.

2. Depending on the different working place, we should chose the rope with different surface treated, includingl galvanized wire rope with lubrication. gal anized wire rope without lubr cation and un-galvanized, total three choices.

3. Be able to bear multiple loads and variable loads.

4. High tensile strength, fatigue strength and impact toughness.

5. Good corrosion resistance and can work normally in the harsh environment of various harmful media.

6. We have awarded several leading international science & technology achievements and many national invention patents. And compiled state standards<General used wire rope sling characteristics and technical conditions> GB/T 16762-2009, <The wire rope sling-Grommet sling> GB/T30587-2014, <Wire rope sling end - Alloy casting socket> GB/T30588-2014. And have participated in compiling state standards <The wire rope sling - splicing sling> GB/T 16271-2009, <Wire rope sling end-sleeved pressing sling >GB/T30589-2014, etc.

Applications

Our wire rope slings are designed to withstand heavy loads and demanding conditions, making them ideal for a diverse range of lifting operations. Whether you need single-leg slings, multi-leg slings, or specialized slings for specific purposes, Juli Sling has you covered. We offer a comprehensive range of wire rope slings crafted from high-quality materials to ensure strength, durability, and long-lasting performance. It is widely used in a variety of lifting, hoisting, and traction equipment.

Also the metallurgical machinery construction field. Such as cranes, construction machinery, shaft lifting, inclined shaft lifting, port loading and unloading, shipbuilding, transportation, mining industry, petroleum, marine engineering, etc.

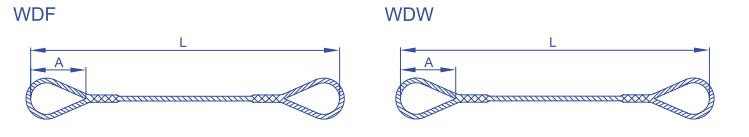

Specifications

| Spliced Steel Wire Rope Sling | |||||

|

|||||

| Art. No. | Dia. of Rope

(mm) |

Working Load Limit | Approx. Eye Length A

(mm) |

||

| FC | IWRC | FC (KN) | IWRC (KN) | ||

| WDF06 | WDW06 | 6 | 2.7 | 2.9 | 180 |

| WDF07 | WDW07 | 7 | 3.6 | 3.9 | 190 |

| WDF08 | WDW08 | 8 | 4.7 | 5.1 | 210 |

| WDF09 | WDW09 | 9 | 6 | 6.5 | 230 |

| WDF10 | WDW10 | 10 | 7.4 | 8 | 230 |

| WDF11 | WDW11 | 11 | 8.9 | 9.7 | 250 |

| WDF12 | WDW12 | 12 | 11 | 11.5 | 260 |

| WDF13 | WDW13 | 13 | 12 | 14 | 260 |

| WDF14 | WDW14 | 14 | 14 | 16 | 280 |

| WDF16 | WDW16 | 16 | 19 | 20 | 320 |

| WDF18 | WDW18 | 18 | 24 | 26 | 360 |

| WDF20 | WDW20 | 20 | 30 | 32 | 400 |

| WDF22 | WDW22 | 22 | 36 | 39 | 440 |

| WDF24 | WDW24 | 24 | 42 | 46 | 480 |

| WDF26 | WDW26 | 26 | 50 | 54 | 520 |

| WDF28 | WDW28 | 28 | 58 | 63 | 560 |

| WDF30 | WDW30 | 30 | 66 | 72 | 600 |

| WDF32 | WDW32 | 32 | 76 | 82 | 640 |

| WDF34 | WDW34 | 34 | 85 | 92 | 680 |

| WDF36 | WDW36 | 36 | 96 | 104 | 720 |

| WDF38 | WDW38 | 38 | 106 | 115 | 760 |

| WDF40 | WDW40 | 40 | 118 | 128 | 800 |

| WDF42 | WDW42 | 42 | 130 | 141 | 840 |

| WDF44 | WDW44 | 44 | 143 | 155 | 880 |

| WDF46 | WDW46 | 46 | 156 | 169 | 920 |

| WDF48 | WDW48 | 48 | 170 | 183 | 960 |

| WDF50 | WDW50 | 50 | 185 | 200 | 1000 |

| WDF52 | WDW52 | 52 | 200 | 216 | 1040 |

| WDF54 | WDW54 | 54 | 215 | 233 | 1080 |

| WDF56 | WDW56 | 56 | 131 | 151 | 1120 |

| WDF58 | WDW58 | 58 | 248 | 269 | 1160 |

| WDF60 | WDW60 | 60 | 266 | 287 | 1200 |

| WDF62 | WDW62 | 62 | 241 | 286 | 1240 |

| WDF64 | WDW64 | 64 | 257 | 304 | 1280 |

| WDF66 | WDW66 | 66 | 274 | 324 | 1320 |

| WDF68 | WDW68 | 68 | 291 | 344 | 1360 |

| WDF70 | WDW70 | 70 | 308 | 365 | 1400 |

| WDF72 | WDW72 | 72 | 326 | 386 | 1440 |

| WDF74 | WDW74 | 74 | 344 | 407 | 1480 |

| WDF76 | WDW76 | 76 | 363 | 430 | 1520 |

| WDF78 | WDW78 | 78 | 383 | 453 | 1560 |

| WDF80 | WDW80 | 80 | 402 | 476 | 1600 |

| WDF82 | WDW82 | 82 | 423 | 500 | 1640 |

| WDF84 | WDW84 | 84 | 444 | 525 | 1680 |

| WDF86 | WDW86 | 86 | 465 | 550 | 1720 |

| WDF88 | WDW88 | 88 | 487 | 576 | 1760 |

| WDF90 | WDW90 | 90 | 509 | 603 | 1800 |

| WDF92 | WDW92 | 92 | 532 | 630 | 1920 |

| WDF94 | WDW94 | 94 | 556 | 657 | 1960 |

| WDF96 | WDW96 | 96 | 579 | 686 | 2000 |

| WDF98 | WDW98 | 98 | 604 | 714 | 2040 |

| WDF100 | WDW100 | 100 | 629 | 805 | 2080 |

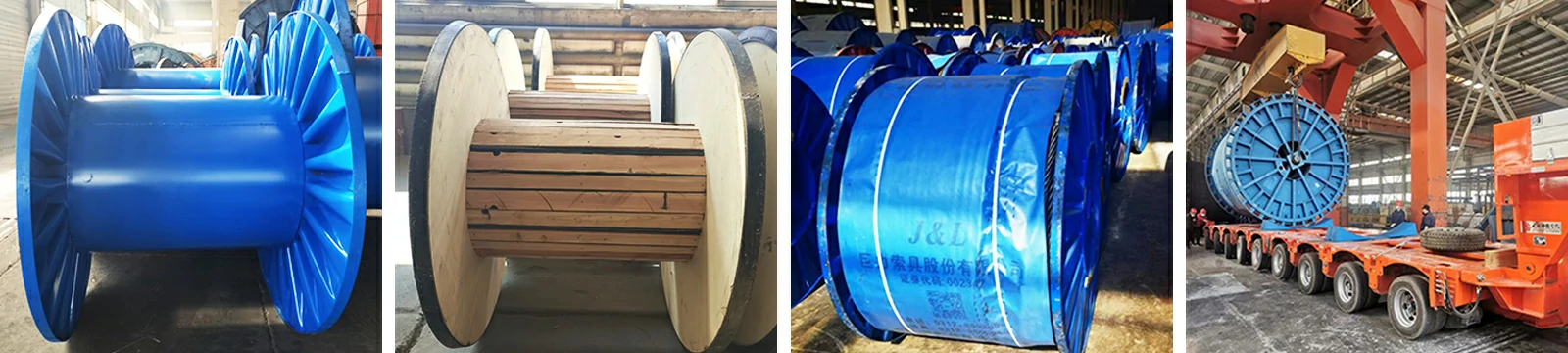

Package

JULI standard export package: Wooden Reel / Steel Wheel Reel

Customized packaging according to customer needs.

Certifications

CE CNAS ISO

Production Process

Steel wire rope sling products including: Marine engineering series (grommet sling, high tension grommet sling,cable-laid sling), construction engineering series (pressed and casting sling), hoisting engineering series (pressed and spliced sling) and specialized slings. Production diameter range: 6mm to 570mm.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.