Steel Wire Rope

Description

1. Product Name: Steel wire rope

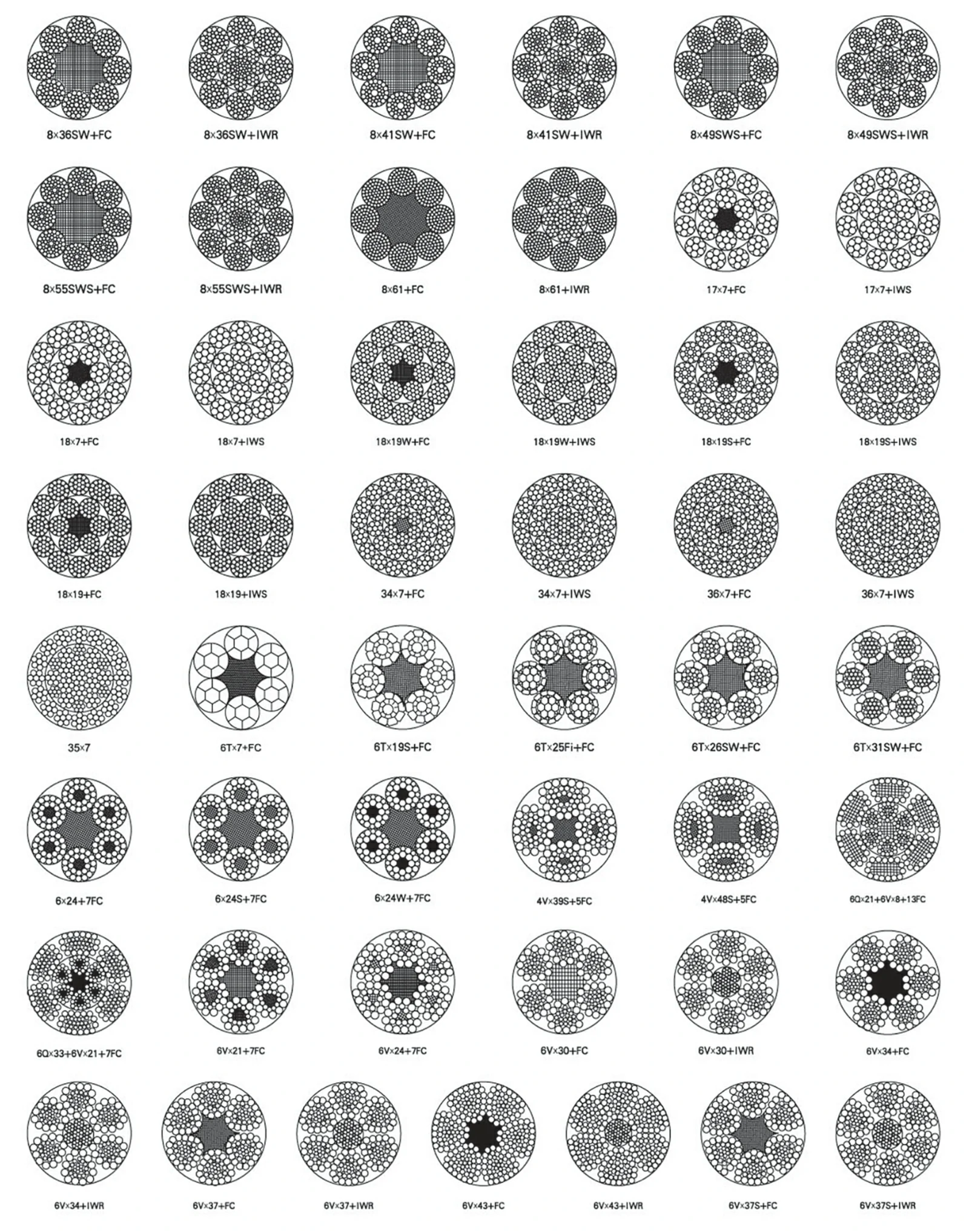

2. Rope Construction:

6×25Fi+FC, 6x26WS+FC, 6×29Fi+FC, 6x31WS+FC, 6x36WS+FC, 6x37+FC, 6x41WS+FC, 6x49SWS+FC, 6x55SWS+FC, 6×25Fi+IWR, 6×26WS+IWR, 6×29Fi+IWR, 6×31WS+IWR, 6×36WS+IWR, 6×37+IWR, 6×41WS+IWR, 6×49SWS+IWR,

6×55SWS+IWR.

6×25Fi: It is used in blast furnace hoisting, petroleum drilling, heavy-duty crane (steel core), heavy lifting and other importantusage of crane, steel heat transfer machine (steel core), Shipping handling.

6×26WS: It is used in blast furnace hoisting, petroleum drilling, heavy lifting and other important usage of crane.

6×29Fi: It is used in blast furnace hoisting. petroleum driling, heavy lifting and other important uses of crane, steel heat transfermachine (steel core), shipping handling.

6×31WS: It is used in blast furnace hoisting, petroleum drilling, heavy lifting and other important uses of crane, steel heattransfer machine (steel core), shipping handling, tow boat, cargo net.

6x36WS: It is used in balance shaft rope (only interactive twist), blast furnace hoisting, petroleum drilling, heavy lifting and otherimportant uses of crane, steel heat transfer machine (steel core), shipping handling, tow boat, cargo net, salvage.

6×37S: It is used in balance shaft rope (only interactive twist), heavy lifting and other important uses of crane, steel heat transfer machine (steel core), shipping handling, tow boat, cargo net, salvage.

6×49SWS, 6×55SWS: It is used in heavy lifting and other important usage of crane, salvage.

3. Rope Nominal Diameter: 16mm~100mm

4. Length: Customized

5. Surface: Galvanized/ Smooth

6. Nominal Tensile Strength: 1570Mpa~2160Mpa

7. Standards: Perform national and international standards, GB/T20118, EN, GOST, API.

8. Place of Origin: Hebei, China

9. Brand Name: J&L

Main Features

1. Advanced Manufacturing Equipment: Equipped with large, medium and small wire rope manufacturing workshops with advanced technology, sophisticated equipment and complete product varieties.

2. Production Capacity: Annual production capacity over 100,000 ton. One of the professional manufacturing bases of wire rope with the largest production volume and specifications in China

3. Well-experienced: Nearly 40 years of OEM&ODM manufacturing and export experience, Professional technical team, Support customized product

4. Standards: Perform national and international standards, GB/T20118, EN , Gost, API.

5. High quality: Strict quality control before,in and after production, Authoritative testing report can be provided

Applications

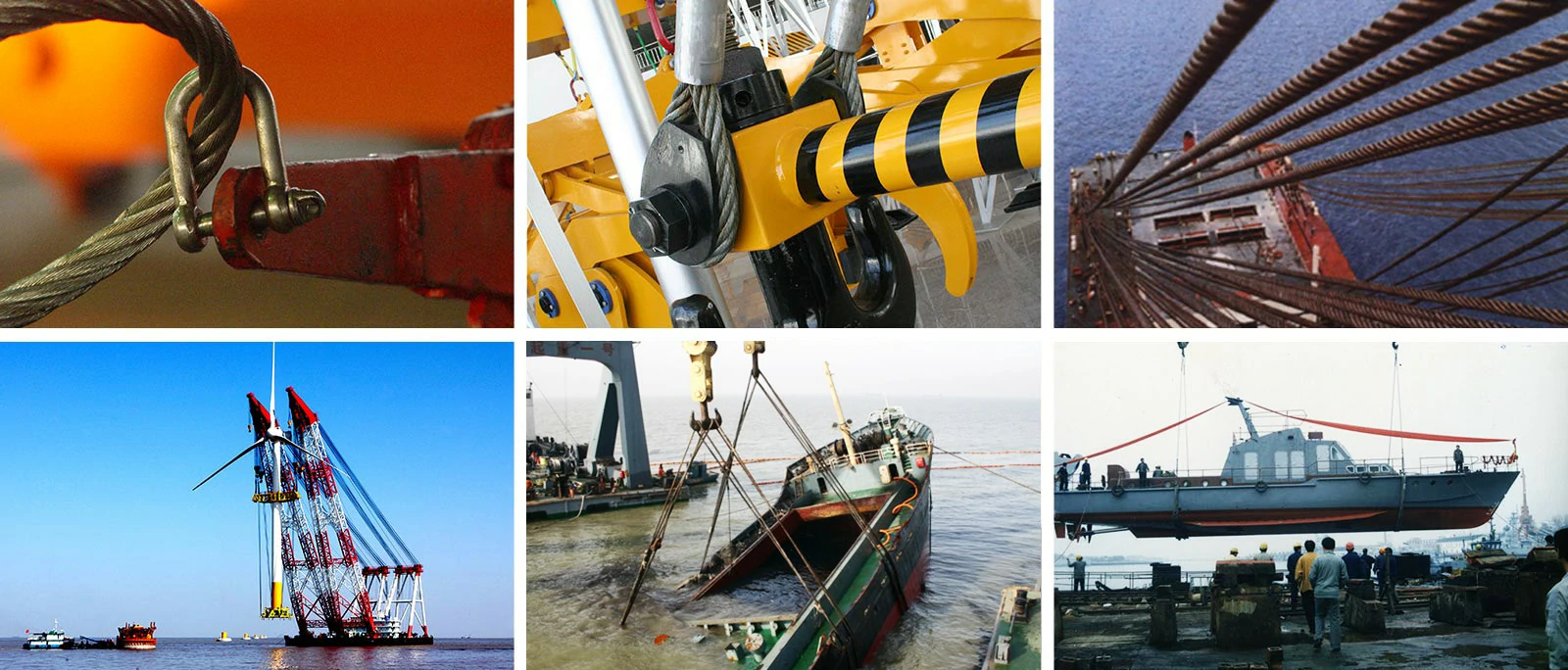

Steel wire rope serves as a fundamental component in a wide array of industries, supporting lifting, pulling, and securing of heavy loads. Its remarkable strength, durability, and resistance to abrasion render it indispensable in applications ranging from cranes and hoists, elevators, and mining to marine operations, construction, and automotive uses. The rope's versatility extends to metallurgical machinery construction, encompassing cranes, construction machinery, shaft lifting, inclined shaft lifting, port operations, shipbuilding, transportation, mining, petroleum, and marine engineering. Whether on construction sites, at sea, or in industrial settings, steel wire rope plays a pivotal role in facilitating the safe and efficient handling of heavy materials and equipment.

Specifications

1. Diameter from 6mm to 260mm with various point and line contacts wire rope, compacted strand wire rope

2. Rope tensile strength grade from 1570Mpa to 2160Mpa

3. Production standard can be the national and international standards

Round Strand Wire Rope |

|||||||

| Rope Type | Typical Construction | Rope Diameter(mm) | Rope Type | Typical Construction | Rope Diameter(mm) | ||

| Wire Rope | Strand | Wire Rope | Strand | ||||

| Single-strand wire rope |

1×7 | (1+6) | 6~16 | 6×24 | 6×24S | (FC+12+12) | 14~44 |

| 1×19 | (1+6+12) | 10~30 | 6×24W | (FC+8+8/8) | 14~44 | ||

| 1×37 | (1+6+12+18) | 14~42 | 8×19 | 8×19S | (1+9+9) | 16~50 | |

| 1×61 | (1+6+12+18+24) | 20~54 | 8×19W | (1+6+6/6) | 16~50 | ||

| 1×91 | (1+6+12+18+24+30) | 30~66 | 8×25Fi | (1+6+6F+12) | 18~56 | ||

| 1×127~1×631 | — | 50~160 | 8×26WS | (1+5+5/5+10) | 16~54 | ||

| 6×7 | 6×7 | (1+6) | 6~36 | 8×31WS | (1+6+6/6+12) | 16~60 | |

| 6×19(a) | 6×19S | (1+9+9) | 12~42 | 8×37(a) | 8×36WS | (1+7+7/7+14) | 18~108 |

| 6×19W | (1+6+6/6) | 12~42 | 8×41WS | (1+8+8/8+16) | 28~120 | ||

| 6×25Fi | (1+6+6F+12) | 16~42 | 8×49SWS | (1+8+8+8/8+16) | 40~120 | ||

| 6×26WS | (1+5+5/5+10) | 16~42 | 8×55SWS | (1+9+9+9/9+18) | 40~124 | ||

| 6×31WS | (1+6+6/6+12) | 18~42 | 8×37(b) | 8×37 | (1+6+12+18) | 60~86 | |

| 6×19(b) | 6×19 | (1+6+12) | 9~46 | 8×61(a) | 8×61FWS | (1+5+5F+10+10/10+20) | 60~136 |

| 6×37(a) | 6×29Fi | (1+7+7F+14) | 18~64 | 8×64SFS | (1+9+9+9F+18+18) | 60~124 | |

| 6×36WS | (1+7+7/7+14) | 16~90 | 8×61(ab) | 8×65FNS | (1+6+6F+12-20+20) | 60~140 | |

| 6×41WS | (1+8+8/8+16) | 38~100 | 8×80WSNS | (1+7+7/7+14-22+22) | 50~158 | ||

| 6×49SWS | (1+8+8+8/8+16) | 38~100 | 8×84WSNS | (1+7+7/7+14-24+24) | 60~172 | ||

| 6×55SWS | (1+9+9+9/9+18) | 38~100 | 8×91(ab) | 8×111SWSNS | (1+9+9+9/9+18-28+28 | 60~156 | |

| 6×37WS | (1+6+15+15) | 16~64 | 8×103FSNS | (1+7+7F+14+14-30+30) | 60~190 | ||

| 6×37(b) | 6×37 | (1+6+12+18) | 13~66 | 8×109SWSNS | (1+8+8+8/8+16-30+30) | 60~190 | |

| 6×61(a) | 6×61FWS | (1+5+5F+10+10/10+20) | 60~110 | 8×61(b) | 8×61 | (1+6+12+18+24) | 60~134 |

| 6×64FS | (1+9+9+9F+18+18) | 60~100 | 18×7 | 17×7 | (1+6) | 12~44 | |

| 6×61(ab) | 6×65FNS | (1+6+6F+12-20+20) | 60~116 | 18×7 | (1+6) | 12~55 | |

| 6×80WSNS | (1+7+7/7+14-22+22) | 60~130 | 18×19 | 18×19S | (1+9+9) | 18~50 | |

| 6×84WSNS | (1+7+7/7+14-24+24) | 60~142 | 18×19W | (1+6+6/6) | 14~50 | ||

| 6×91(ab) | 6×111SWSNS | (1+9+9+9/9+18-28+28) | 60~128 | 18×19 | (1+6+12) | 14~50 | |

| 6×103FSNS | (1+7+7F+14+14-30+30) | 60~156 | 34×7 | 34×7 | (1+6) | 16~60 | |

| 6×109SWSNS | (1+8+8+8/8+16-30+30) | 60~156 | 36×7 | (1+6) | 16~60 | ||

| 6×61(b) | 6×61 | (1+6+12+18+24) | 40~110 | 35W×7 | 35W×7 | (1+6) | 16~60 |

| 6×12 | 6×12 | (FC+12) | 8~32 | 24W×7 | (1+6) | 16~50 | |

| 6×24 | 6×24 | (FC+9+15) | 30~46 | ||||

Shaped Strand Wire Rope |

|||||||

| Rope Type | Typical Construction | Rope Diameter(mm) | Rope Type | Typical Construction | Rope Diameter(mm) | ||

| Wire Rope | Strand | Wire Rope | Strand | ||||

| 4V×39 | 4V×39S | (FC+9+15+15) | 14~46 | 6V×19 | 6V×30 | (6+12+12) | 22~38 |

| 4V×48S | (FC+12+18+18) | 20~50 | 6V×34 | (/1×7+3/+12+12) | 28~44 | ||

| 6V×7 | 6V×19 | (/1×7+3/+9) | 20~36 | 6V×37 | 6V×37 | (/1×7+3/+12+15) | 32~52 |

| 6V×19 | 6V×21 | (FC+9+12) | 18~36 | 6V×37S | (/1×7+3/+12+15) | 32~52 | |

| 6V×24 | (FC+12+12) | 18~36 | 6V×43 | (/1×7+3/+15+18) | 38~58 | ||

Compacted Strand Wire Rope |

|||||||

| Rope Type | Typical Construction | Rope Diameter(mm) | Rope Type | Typical Construction | Rope Diameter(mm) | ||

| Wire Rope | Strand | Wire Rope | Strand | ||||

| 6×K7 | 6×K7 | 1+6 | 10~40 | 8×K36-PWRC(K) | 8×K36WS-PWRC(K) | 1+7+7/7+14 | 22~60 |

| 6×K19 | 6×K19S | 1+9+9 | 12~40 | 15×K7 | 15×K7 | 1+6 | 22~60 |

| 6×K26WS | 1+5+5/5+10 | 14~40 | 16×K7 | 16×K7 | 1+6 | 22~60 | |

| 6×K31WS | 1+6+6/6+12 | 16~40 | 18×K7 | 18×K7 | 1+6 | 14~48 | |

| 6×K36 | 6×K36WS | 1+7+7/7+14 | 24~68 | 18×K9 | 18×K9S | 1+9+9 | 24~60 |

| 6×K41WS | 1+8+8/8+16 | 38~68 | 35W×K7 | 35W×K7 | 1+6 | 14~42 | |

| 8×K19 | 8×K17S | 1+8+8 | 16~38 | 35W×K19S | 1+9+9 | 35~52 | |

| 8×K19S | 1+9+9 | 16~40 | 35W×K26WS | 1+5+5/5+10 | 40~60 | ||

| 8×K26WS | 1+5+5/5+10 | 20~42 | JL·1618K | JL·1618K | 1+6 | 18~60 | |

| 8×K31WS | 1+6+6/6+12 | 24~50 | JL·1710K | JL·1710K26WS | 1+5+5/5+10 | 20~50 | |

| 8×K36 | 8×K36WS | 1+7+7/7+14 | 28~78 | JL·1710K31WS | 1+6+6/6+12 | 20~50 | |

| 8×K41WS | 1+8+8/8+16 | 30~78 | JL·1710K36WS | 1+7+7/7+14 | 30~50 | ||

| 8×K19-PWRC(K) | 8×K19S-PWRC(K) | 1+9+9 | 20~48 | JL·1712K | JL·1712K7 | 1+6 | 20~40 |

| 8×K26WS-PWRC(K) | 1+5+5/5+10 | 20~48 | JL·1710K719S | 1+9+9 | 30~60 | ||

| 8×K31WS-PWRC(K) | 1+6+6/6+12 | 20~56 | |||||

Steel Cable |

|||||||

| Rope Type | Typical Construction | Rope Diameter(mm) | Rope Type | Typical Construction | Rope Diameter(mm) | ||

| Wire Rope | Strand | Wire Rope | Strand | ||||

| 7×[6×37(a)+IWR] | 6×[6×36WS+IWR]+IWRC | 192~260 | 9×[6×37(a)+IWR] | 8×[6×36WS+IWR]+IWRC | 192~260 | ||

| 6×[6×41WS+IWR]+IWRC | 192~260 | 8×[6×41WS+IWR]+IWRC | 192~260 | ||||

| 6×[6×49SWS+IWR]+IWRC | 192~260 | 8×[6×49SWS+IWR]+IWRC | 192~260 | ||||

| 7×[6×61(a)+IWR] | 6×[6×55SWS+IWR]+IWRC | 192~260 | 9×[6×61(a)+IWR] | 8×[6×55SWS+IWR]+IWRC | 192~260 | ||

| 6×[6×61FWS+IWR]+IWRC | 192~260 | 8×[6×61FWS+IWR]+IWRC | 192~260 | ||||

| 6×[6×64SFS+IWR]+IWRC | 192~260 | 6×[6×64SFS+IWR]+IWRC | 192~260 | ||||

| 7×[6×37(b)+IWR] | 6×[6×37+IWR]+IWRC | 192~260 | 9×[6×37(b)+IWR] | 8×[6×37+IWR]+IWRC | 192~260 | ||

| 7×[6×61(b)+IWR] | 6×[6×61+IWR]+IWRC | 192~260 | 9×[6×61(b)+IWR] | 8×[6×61+IWR]+IWRC | 192~260 | ||

Compacted Strand Wire Rope for Enhanced Strength and Durability

Our compacted strand wire ropes are designed to deliver exceptional strength and durability. By compacting the individual wire strands, we increase the wire rope's resistance to abrasion, crushing, and fatigue, extending its lifespan and improving performance. Whether you need compacted strand wire ropes for heavy lifting, towing, or rigging applications, Juli Sling has you covered.

Diverse Range of Steel Wire Ropes to Meet Your Requirements

We understand that different industries have unique demands. That's why we provide a diverse range of steel wire ropes to meet your specific requirements. Whether you need wire ropes for general-purpose lifting, heavy-duty applications, or extreme environments, Juli Sling offers a comprehensive selection. Explore our product catalog to find the perfect steel wire rope for your project.

Superior Quality and Reliable Performance

At Juli Sling, we prioritize quality and performance. Our steel wire ropes undergo stringent quality control processes to ensure they meet or exceed industry standards. With premium-grade materials and precise manufacturing techniques, our wire ropes deliver the strength, durability, and reliability you expect. Trust Juli Sling for wire rope solutions that enhance the safety and efficiency of your operations.

Steel Cable and Steel Wire Rope Supplier You Can Rely On

When it comes to sourcing steel cables and steel wire ropes, Juli Sling is your trusted partner. With our extensive experience, technical expertise, and commitment to customer satisfaction, we have earned a reputation as a reliable supplier. Experience our excellent products, exceptional customer service, and competitive pricing when you choose Juli Sling as your steel cable and steel wire rope supplier.

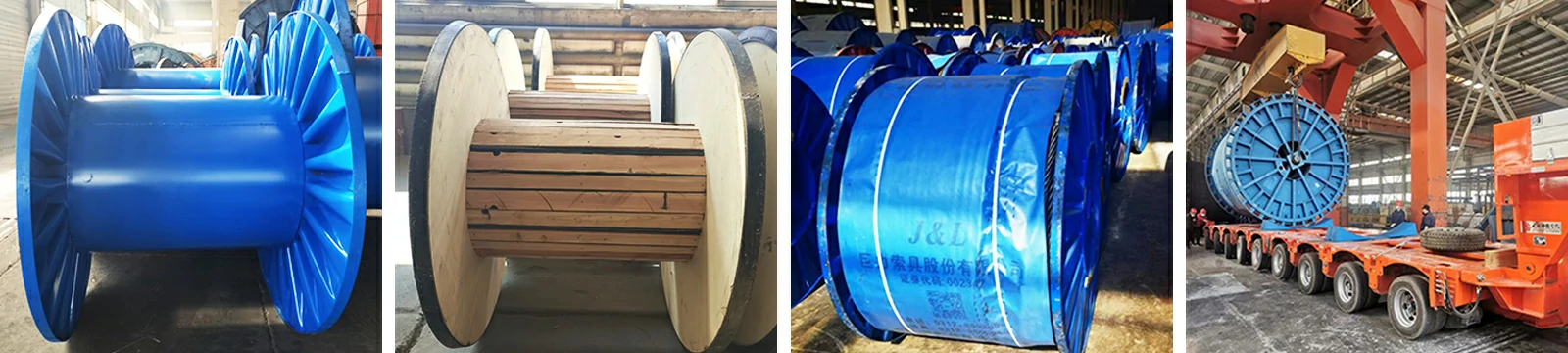

Package

JULI standard export package: Heat shrinking film packaging + Carton + PalletCustomized packaging according to customer needs.

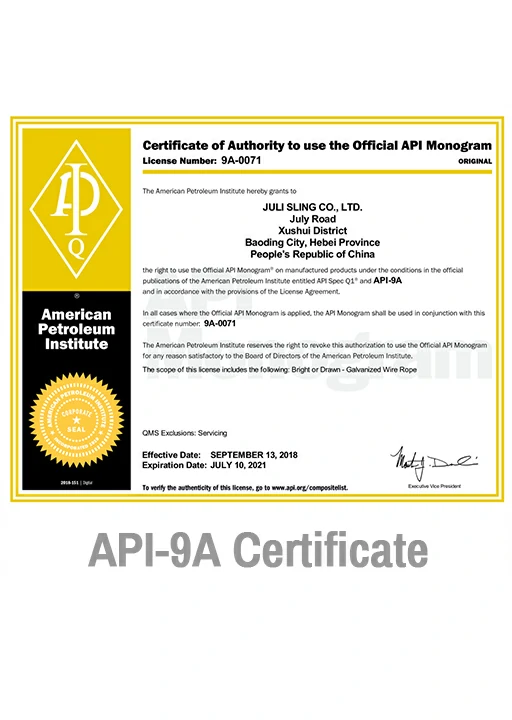

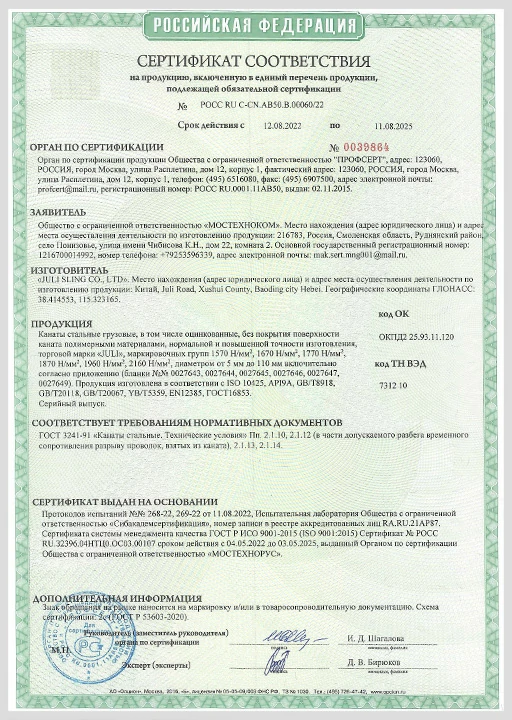

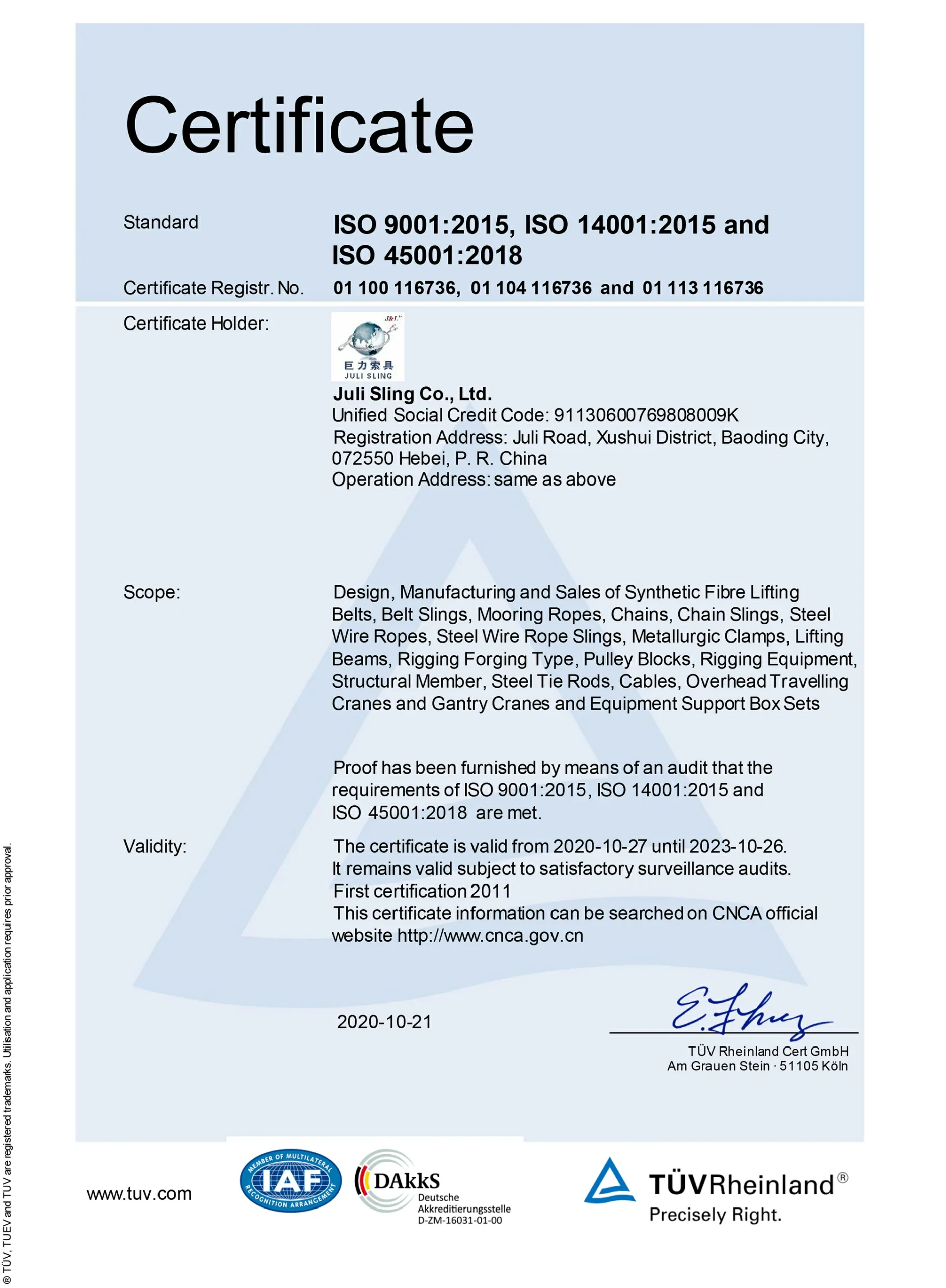

Certifications

API GOST ISO

Production Process

JULI steel wire rope sling factory is has a wide production line, equipped with the strongest technical force and the most thoughtful after-sale service. Possess the largest 10,000T pressing machine, and it should be the largest one in Asia market. Several heavy duty equipment have got the patent for inventing, including: horizontal turning grommet sling machine, horizontal vertical grommet sling machine and large-scaled horizontal steel cable splicing machine, etc.Production process is Wire rod、Drawing、Heat Treatment、Galvanized、Secondary Drawing、Stranding、Mixed Rope、Pretension、Packaging.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.

📄 Catalogue

.png)