6×36WS+IWR Steel Core Steel Wire Rope

Description

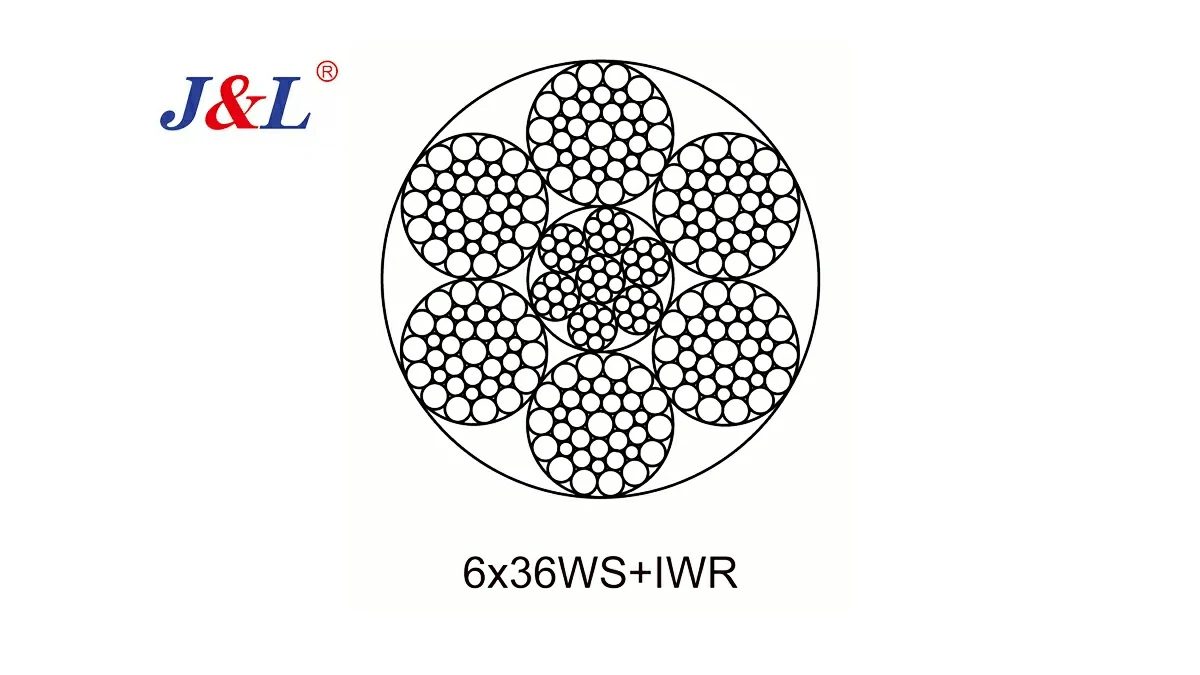

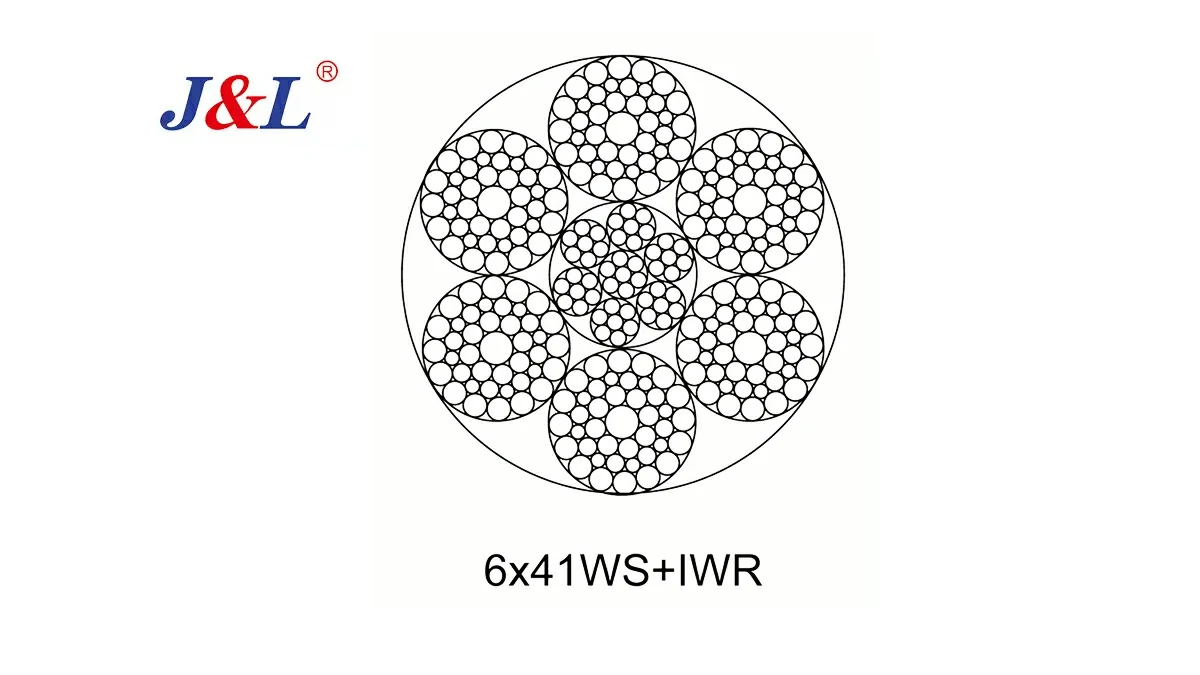

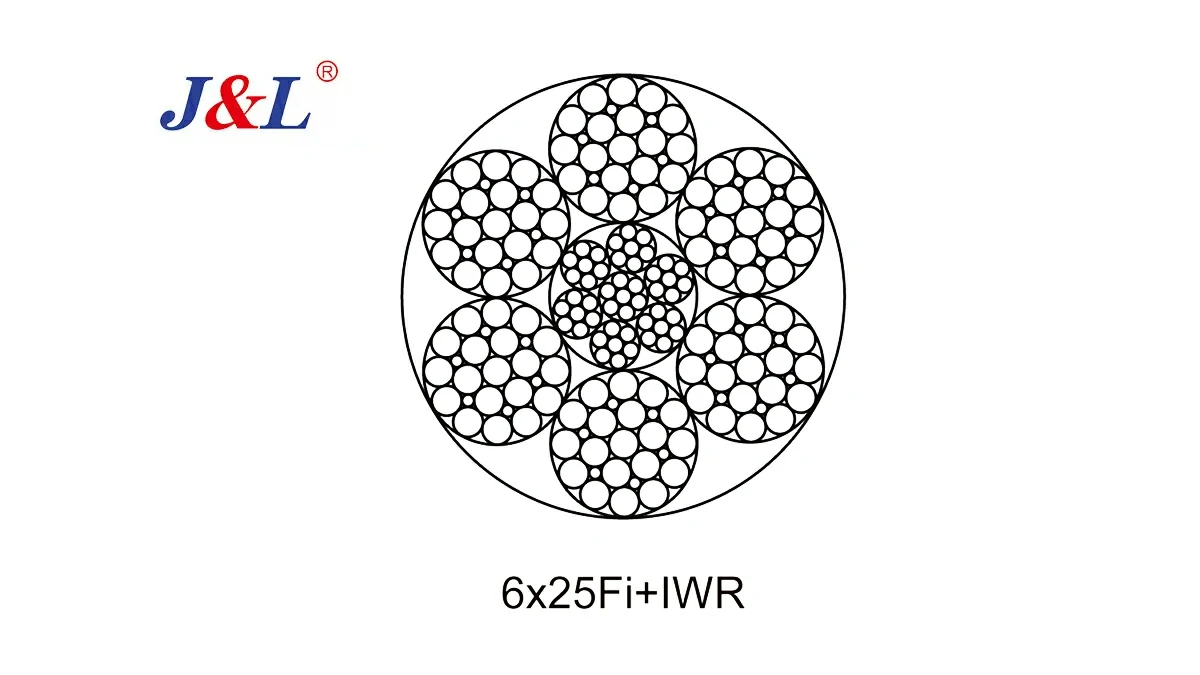

1. Product Type: Round strand wire rope(The inner core is steel core).

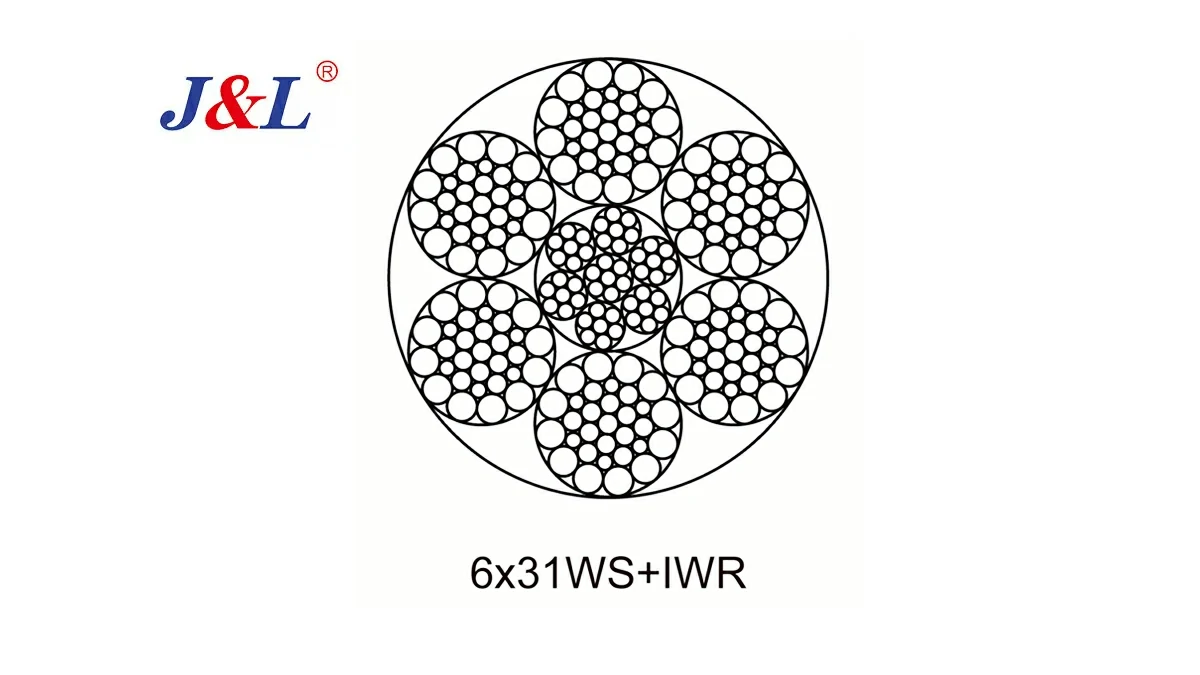

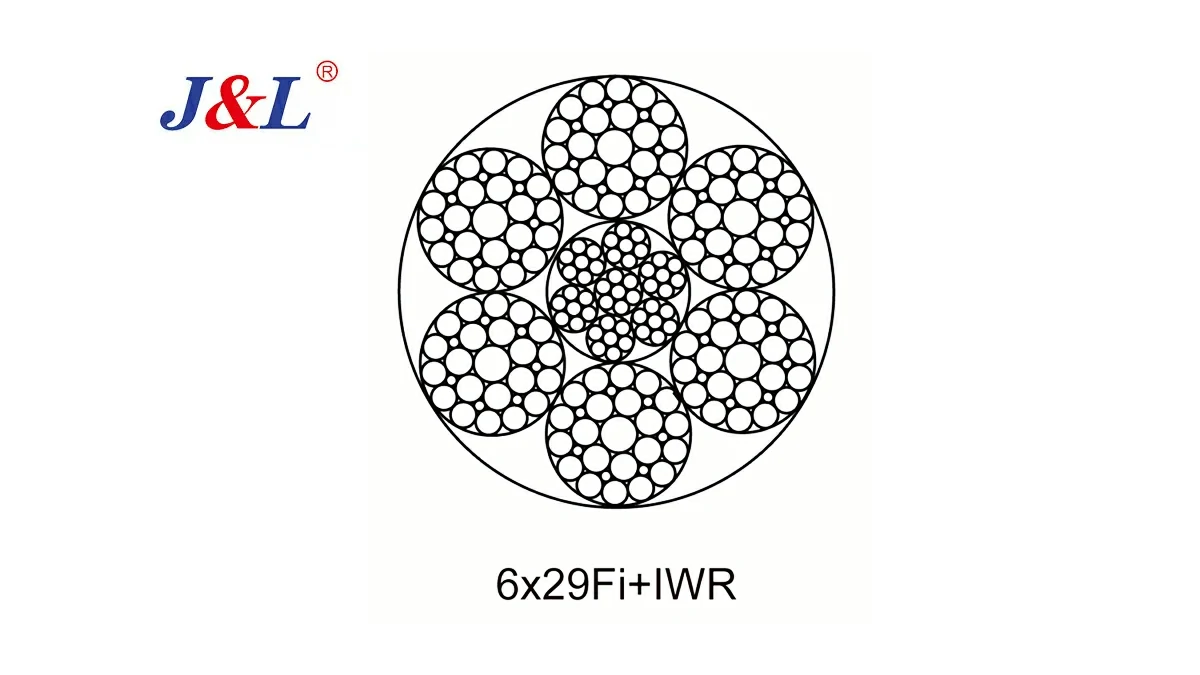

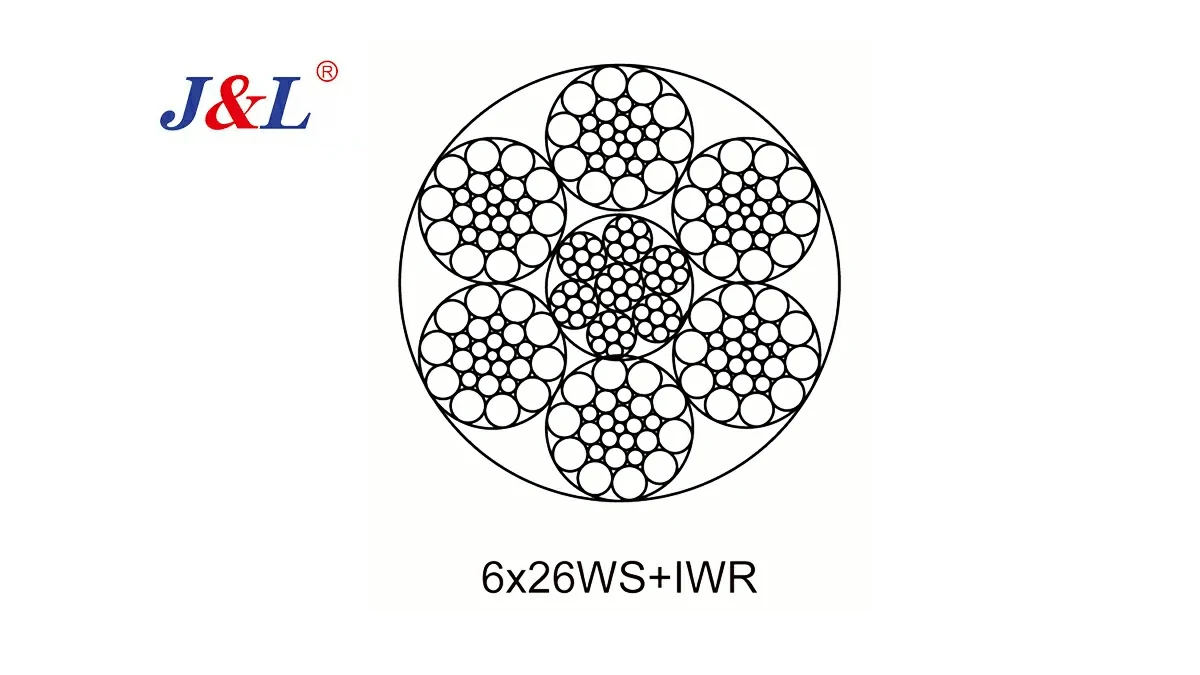

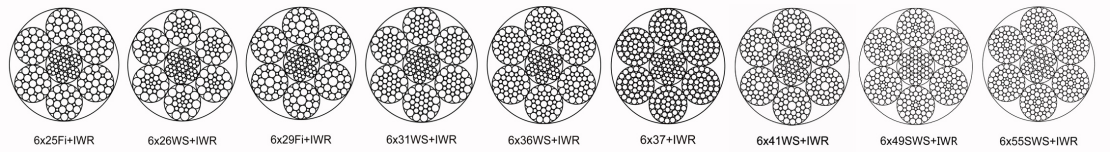

2. Rope Construction:

6×25Fi+IWR, 6×26WS+IWR, 6×29Fi+IWR, 6×31WS+IWR, 6×36WS+IWR, 6×37+IWR, 6×41WS+IWR, 6×49SWS+IWR, 6×55SWS+IWR

4. Surface: Galvanized/ Smooth

5. Rope Nominal Diameter: 16mm~100mm

6. Length: Customized

7. Nominal Tensile Strength: 1570Mpa~2160Mpa

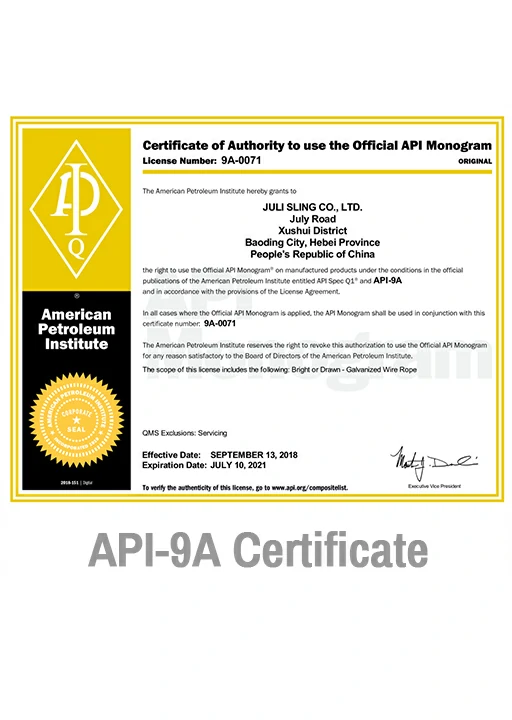

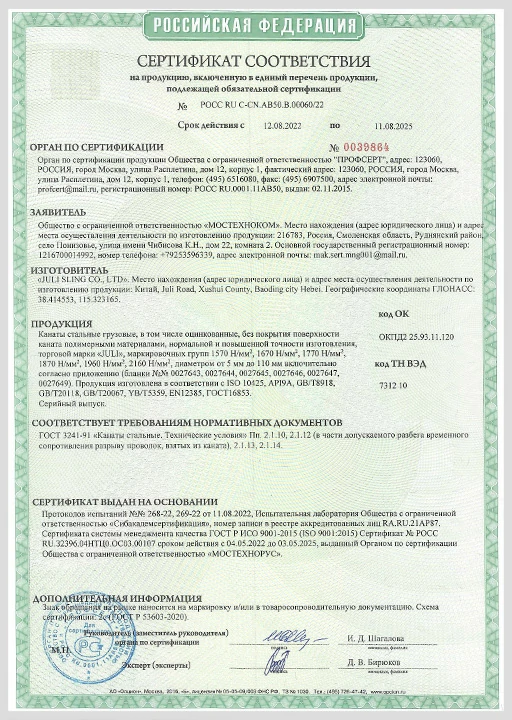

8. Standards: Perform national and international standards, GB/T20118, EN, GOST, API.

9. Place of Origin: Hebei, China

10. Brand Name: J&L

Main Features

1. Advanced Manufacturing Equipment: Equipped with large, medium and small wire rope manufacturing workshops with advanced technology, sophisticated equipment and complete product varieties.

2. Production Capacity: Annual production capacity over 100,000 ton. One of the professional manufacturing bases of wire rope with the largest production volume and specifications in China.

3. Well-experienced: Nearly 40 years of OEM&ODM manufacturing and export experience, Professional technical team, Support customized product.

4. Standards: Perform national and international standards, GB/T20118, EN, GOST, API.

5. High quality: Strict quality control before,in and after production. Authoritative testing report can be provided. Ensuring steel wire rope has the following advantages: Transmit long distance load. The bearing safety factor is large, and the use is safe and reliable. Be able to bear multiple loads and variable loads. High tensile strength, fatigue strength and impact toughness. Wear-resistant, anti-seismic and stable in operation at high speed. Good corrosion resistance and can work normally in the harsh environment of various harmful media.

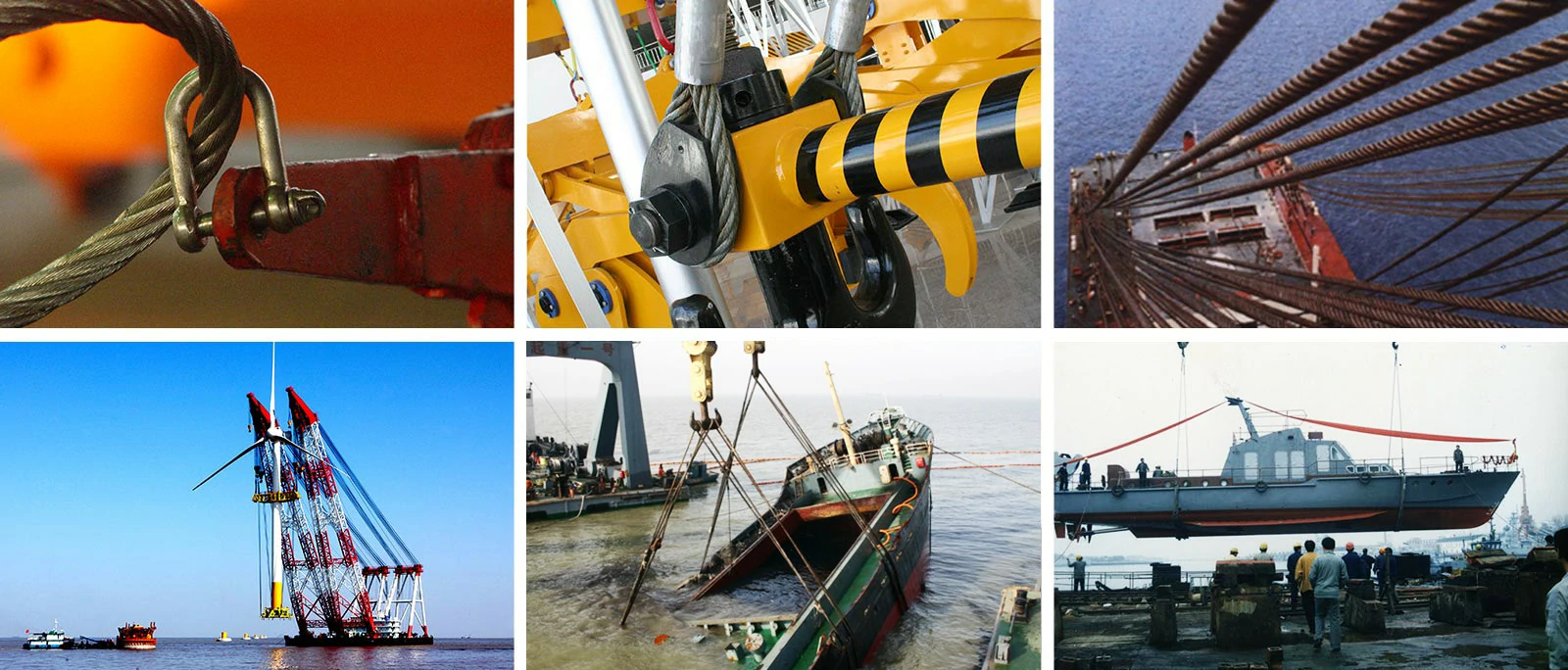

Applications

It is widely used in a variety of lifting, hoisting, and traction equipment.

Also the metallurgical, machinery construction field. Such as cranes, construction machinery, shaft lifting, inclined shaft lifting, port loading and unloading, shipbuilding, transportation, mining industry, petroleum, and marine engineering, etc.

Specifications

| Round Strand Wire Rope | |||||||||

|

|||||||||

| Rope Nominal Diameter(mm) |

Approx. Weight(kg/100m) | Nominal Tensile Strength(Mpa) | |||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | ||||

| Minimum Breaking Strength(KN) | |||||||||

| Natural Fiber Core |

Synthetic Fiber Core |

Steel Core |

Steel Core | ||||||

| 16 | 97.3 | 95 | 107 | 143 | 152 | 161 | 170 | 179 | 197 |

| 18 | 123 | 120 | 135 | 181 | 193 | 204 | 216 | 226 | 249 |

| 20 | 152 | 148 | 167 | 224 | 238 | 252 | 266 | 279 | 308 |

| 22 | 184 | 180 | 202 | 271 | 288 | 305 | 322 | 338 | 372 |

| 24 | 219 | 214 | 241 | 322 | 342 | 363 | 383 | 402 | 443 |

| 26 | 257 | 251 | 283 | 378 | 402 | 426 | 450 | 472 | 520 |

| 28 | 298 | 291 | 328 | 438 | 466 | 494 | 522 | 547 | 603 |

| 30 | 342 | 334 | 376 | 503 | 535 | 567 | 599 | 628 | 692 |

| 32 | 389 | 380 | 428 | 572 | 609 | 645 | 682 | 715 | 787 |

| 34 | 439 | 429 | 483 | 646 | 687 | 728 | 770 | 807 | 889 |

| 36 | 492 | 481 | 542 | 724 | 770 | 817 | 863 | 904 | 997 |

| 38 | 549 | 536 | 604 | 807 | 858 | 910 | 961 | 1010 | 1110 |

| 40 | 608 | 594 | 669 | 894 | 951 | 1010 | 1070 | 1120 | 1230 |

| 42 | 670 | 654 | 737 | 986 | 1050 | 1110 | 1170 | 1230 | 1360 |

| 44 | 736 | 718 | 809 | 1080 | 1150 | 1220 | 1290 | 1350 | 1490 |

| 46 | 804 | 785 | 884 | 1180 | 1260 | 1330 | 1410 | 1480 | 1630 |

| 48 | 876 | 855 | 963 | 1290 | 1370 | 1450 | 1530 | 1610 | 1770 |

| 50 | 950 | 928 | 1040 | 1400 | 1490 | 1580 | 1660 | 1740 | 1920 |

| 52 | 1030 | 1000 | 1130 | 1510 | 1610 | 1700 | 1800 | 1890 | 2080 |

| 54 | 1110 | 1080 | 1220 | 1630 | 1730 | 1840 | 1940 | 2030 | 2240 |

| 56 | 1190 | 1160 | 1310 | 1750 | 1860 | 1980 | 2090 | 2190 | 2410 |

| 58 | 1280 | 1250 | 1410 | 1880 | 2000 | 2120 | 2240 | 2350 | 2590 |

| 60 | 1370 | 1340 | 1500 | 2010 | 2140 | 2270 | 2400 | 2510 | 2770 |

| 62 | 1470 | -- | 1610 | 2150 | 2290 | 2420 | 2560 | 2680 | -- |

| 64 | 1570 | -- | 1710 | 2290 | 2440 | 2580 | 2730 | 2860 | -- |

| 66 | 1670 | -- | 1820 | 2430 | 2590 | 2740 | 2900 | 3040 | -- |

| 68 | 1770 | -- | 1930 | 2580 | 2750 | 2910 | 3080 | 3230 | -- |

| 70 | 1880 | -- | 2050 | 2740 | 2910 | 3090 | 3260 | 3420 | -- |

| 72 | 1990 | -- | 2170 | 2900 | 3080 | 3270 | 3450 | 3620 | -- |

| 74 | 2100 | -- | 2290 | 3060 | 3260 | 3450 | 3650 | 3820 | -- |

| 76 | 2210 | -- | 2410 | 3230 | 3430 | 3640 | 3850 | 4030 | -- |

| 78 | 2330 | -- | 2540 | 3400 | 3620 | 3830 | 4050 | 4250 | -- |

| 80 | 2450 | -- | 2680 | 3580 | 3800 | 4030 | 4260 | 4470 | -- |

| 82 | 2580 | -- | 2810 | 3760 | 4000 | 4240 | 4480 | 4690 | -- |

| 84 | 2700 | -- | 2950 | 3940 | 4190 | 4450 | 4700 | 4920 | -- |

| 86 | 2830 | -- | 3090 | 4130 | 4400 | 4660 | 4920 | 5160 | -- |

| 88 | 2970 | -- | 3240 | 4330 | 4600 | 4880 | 5160 | 5400 | -- |

| 90 | 3100 | -- | 3390 | 4530 | 4820 | 5100 | 5390 | 5650 | -- |

| 92 | 3240 | -- | 3540 | 4730 | 5030 | 5330 | 5630 | 5910 | -- |

| 94 | 3380 | -- | 3690 | 4940 | 5250 | 5570 | 5890 | 6170 | -- |

| 96 | 3530 | -- | 3850 | 5150 | 5480 | 5810 | 6140 | 6430 | -- |

| 98 | 3680 | -- | 4010 | 5370 | 5710 | 6050 | 6390 | 6700 | -- |

| 100 | 3830 | -- | 4180 | 5590 | 5950 | 6300 | 6660 | 6980 | -- |

| Note: Steel wire min. aggregate breaking strength = Min. breaking strength of steel wire rope× 1.226 (fiber core) or 1.321 (steel core), thereinto, 6×37S fiber core is 1.191, steel core is 1.283. | |||||||||

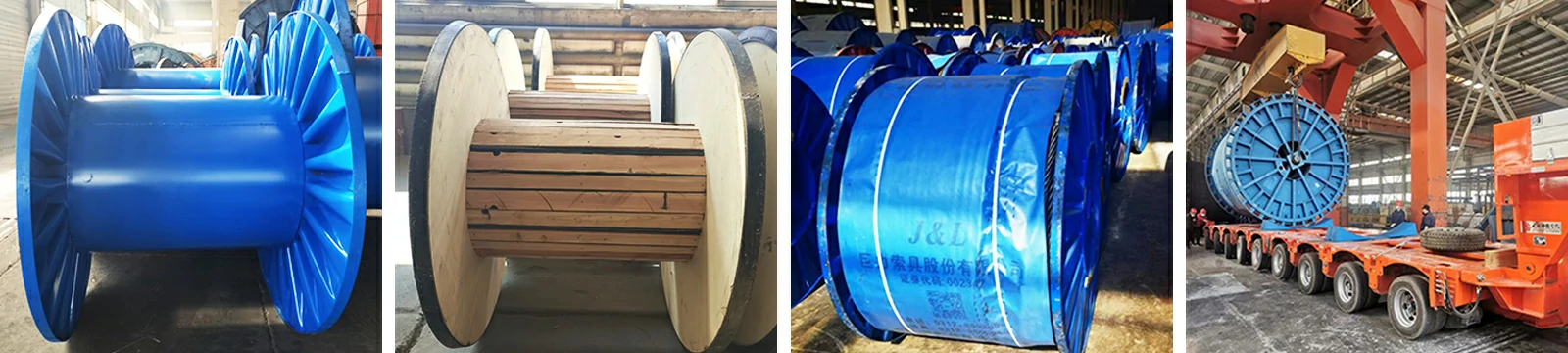

Package

JULI standard export package: Wooden Reel / Steel Wheel Reel

Customized packaging according to customer needs.

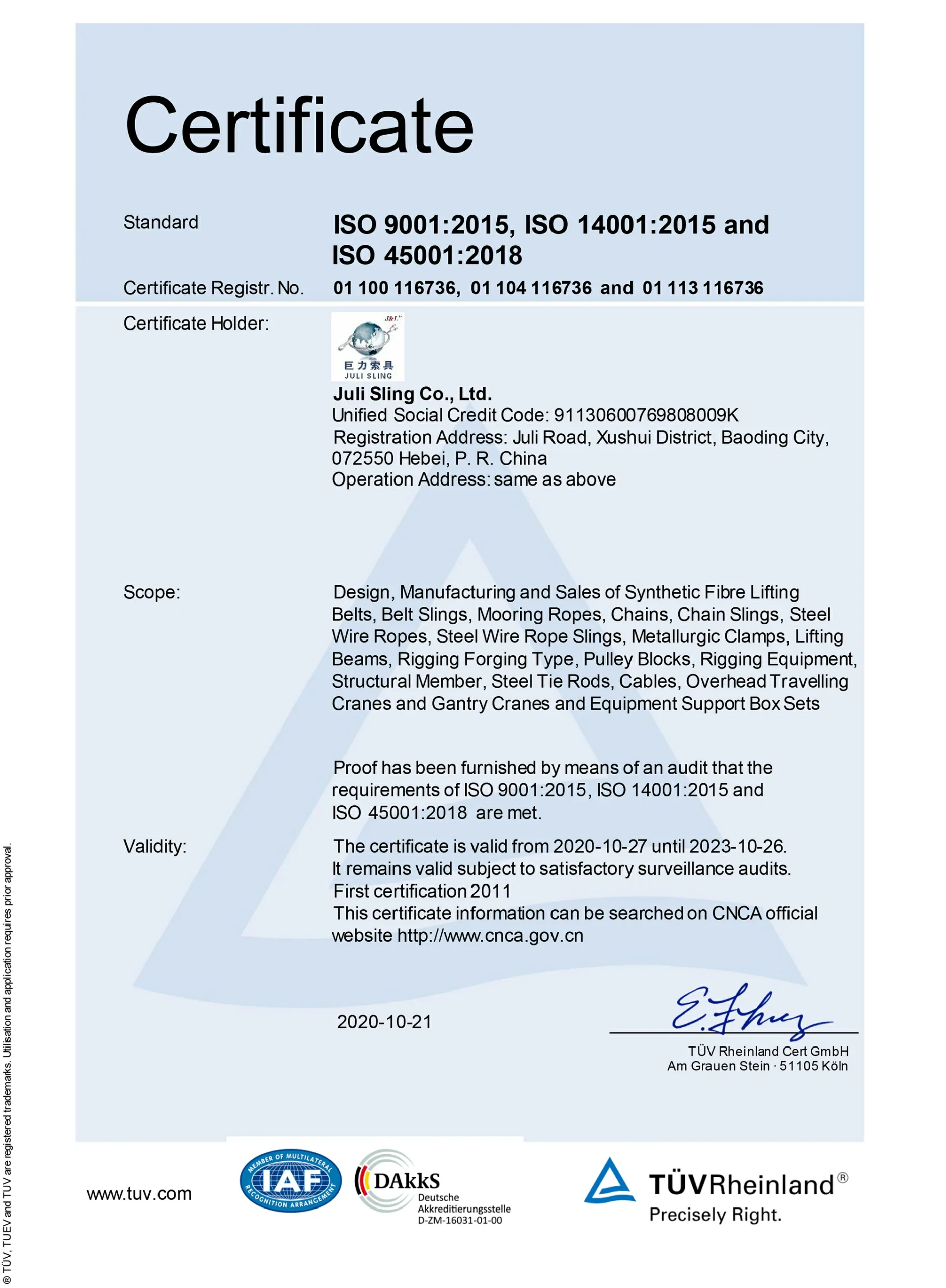

Certifications

API GOST ISO

Production Process

JULI's steel wire rope sling factory has a wide production line, equipped with the strongest technical force and the most thoughtful after-sale service. Possess the largest 10,000T pressing machine, and it should be the largest one in Asia market. Several heavy duty equipment have got the patent for inventing, including: horizontal turning grommet sling machine, horizontal vertical grommet sling machine and large-scaled horizontal steel cable splicing machine, etc. Production process includes Wire rod, Drawing, Heat Treatment, Galvanized, Secondary Drawing, Stranding, Mixed Rope, Pretension, and Packaging.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.