Lifting Sling

JULI offers a wide range of textile sling solutions to meet diverse lifting needs. Our slings are available in polyester, nylon, and synthetic materials, suitable for lifting machinery, steel structures, containers, and other heavy loads.

Each sling is rigorously tested and certified to meet CE, GS, and JIS standards, ensuring reliable performance and safety.

Whether you need standard slings or custom lifting solutions, JULI provides high-quality products and professional support.

Contact us to learn more about our textile sling offerings.

-

High Tensile Endless Round Sling RH01-06

-

High Tensile Endless Round Sling RH01-08

-

High Tensile Endless Round Sling RH01-10

-

Fireproof Endless Round Sling RK01-01

-

RH02 High Tensile Eye Type Round Sling

-

RK02-Fireproof Eye Round Sling

-

Special Sling For Petroleum Pipeline

Textile slings are widely used in modern lifting operations for their strength, safety, and flexibility. Unlike traditional chains or wire ropes, they are lightweight, easy to handle, and gentle on the load surface. At JULI, we provide a wide range of rigging slings for construction, logistics, shipping, and heavy manufacturing, backed by international certifications and a competitive factory price.

Types of Lifting Slings

We supply different sling categories to meet diverse lifting requirements:

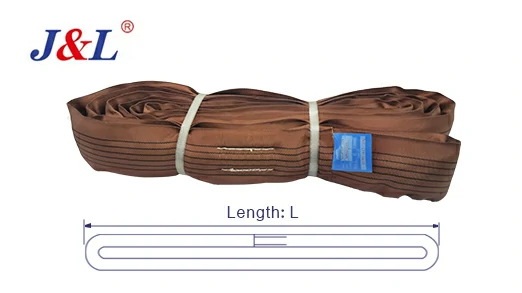

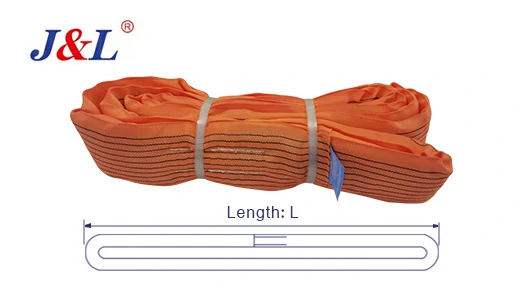

Webbing Slings

Made from synthetic fibers, webbing slings are ideal for straight lifts. They are available in multiple capacities, such as sling belt 3 ton and sling belt 5 ton, offering reliable solutions from light-duty handling to heavy-load applications.

Round Slings

Round slings are designed with an endless loop structure that distributes pressure evenly, reducing wear on both the sling and the load. Both polyester and nylon materials can be used to manufacture round slings, ensuring adaptability across different working environments.

Endless Round Slings

Also known in the industry as sling endless, these flexible and lightweight slings provide excellent contact with the load. They are especially suitable for irregular-shaped or delicate objects, where load protection is critical.

Rope Slings for Lifting

Durable and dependable, rope slings for lifting are widely applied in construction sites, shipyards, and other demanding environments. Their strength and long service life make them a reliable option for heavy-duty tasks.

Each lifting sling strap is tested in our CNAS-approved laboratory to meet CE, GS, and JIS certifications, ensuring safety and consistency in every product.

Material Options

The choice of sling material directly affects durability and application. JULI offers different options to match your specific lifting requirements:

Polyester Slings

Polyester webbing slings deliver excellent resistance to moisture, UV rays, and chemicals, making them suitable for most lifting environments. They are durable yet lightweight, offering high performance in general and industrial lifting.

Nylon Slings

Nylon slings provide elasticity and shock absorption, making them ideal for dynamic or heavy-impact loads. Their flexibility ensures secure lifting while minimizing stress on both equipment and goods.

Synthetic Slings

As versatile solutions, synthetic slings combine the advantages of advanced fibers to achieve strength, surface protection, and a long service life.

Recommended Products

We recommend our best-selling lifting solutions such as polyester webbing slings and nylon round slings. For tailored advice and a product selection that fits your specific application, welcome to contact our team for professional guidance.

Advantages of JULI Slings

Our textile slings are trusted worldwide because of their proven benefits:

-

Quality Safe Lifting Solutions – Engineered and tested to meet strict international standards.

-

Competitive Factory Price – Delivering strong value without compromising performance.

-

Wide Range of Rigging Products – From sling belts to rigging slings, JULI covers every lifting demand.

-

One-Stop-Sourcing OEM Solution – Flexible customization to support global clients.

Why Choose Textile Slings?

Compared with steel ropes or chains, textile slings are easier to carry, store, and operate. Their lightweight design reduces operator fatigue, while the soft surface avoids damage to sensitive or fragile loads. This makes textile slings the preferred choice for industries that value both efficiency and safety.

Applications

Lifting slings are designed to carry, lift, tow, or pull loads ranging from 2 to 24 tons. Slings are often color-coded to indicate their weight capacity, making it easy to select the right sling for each task.

Heavy-duty slings are commonly used with cranes, hoists, or other lifting equipment to safely handle large objects such as machinery, steel beams, containers, and industrial equipment.

Each sling has a specific working load limit (WLL) that must never be exceeded. Always follow the manufacturer’s guidelines and ensure the sling’s capacity matches the weight of the load for safe and efficient operations.

Customized Package

JULI standard export package: Heat shrinking film packaging + Carton + Pallet

Customized packaging according to customer needs

Production capacity: We can produce customised products for different applications and customer requirements.

Production process: Beam Warping—Weaving —Dyeing —Sewing —Clean & iron—Taping—Finished Products

Conclusion

JULI provides a complete range of textile sling solutions, supported by certified production and strict quality testing. With our strong product portfolio and OEM capabilities, we are ready to deliver reliable and cost-effective lifting equipment for your projects. Whether you require sling belts, rope slings for lifting, or customized rigging slings, JULI is your trusted partner for safe and efficient operations.