The 5-Step Guide to Selecting and Using Certified Lifting Slings in 2025

August 27, 2025

Abstract

The domain of industrial lifting and rigging demands an unwavering commitment to safety and precision, where the integrity of equipment directly correlates with the prevention of catastrophic failures. This guide examines the principles governing the selection and application of certified lifting slings, pivotal components in material handling across construction, manufacturing, and maritime sectors. An exploration into the material science, engineering mechanics, and regulatory frameworks that define these tools reveals a complex interplay of factors. The analysis focuses on the critical parameters of Working Load Limit (WLL), safety factors, and the profound effects of sling angle on load-bearing capacity. It differentiates between various sling types—synthetic, wire rope, and chain—evaluating their suitability for diverse operational contexts based on load characteristics and environmental conditions. The discourse emphasizes the non-negotiable role of rigorous, multi-tiered inspection protocols and proper maintenance in extending equipment lifespan and ensuring compliance with international standards such as those set by ASME and ISO. The objective is to equip professionals with the nuanced understanding required for responsible and effective use of certified lifting slings, thereby fostering a culture of safety and operational excellence.

Key Takeaways

- Always verify a sling's certification tag before any lift.

- Calculate the sling angle to avoid overloading the equipment.

- Select the correct sling material for your specific load and environment.

- Conduct a visual inspection of your certified lifting slings before each use.

- Adhere to the Working Load Limit (WLL) without exception.

- Protect slings from sharp edges to prevent catastrophic failure.

- Properly document all periodic inspections for compliance.

Table of Contents

- Step 1: Understanding the Fundamentals of Certified Lifting Slings

- Step 2: Assessing the Load and Environment

- Step 3: Selecting the Appropriate Certified Lifting Sling

- Step 4: The Rigorous Inspection Protocol

- Step 5: Mastering Safe Use and Proper Storage

Step 1: Understanding the Fundamentals of Certified Lifting Slings

Embarking on any lifting operation without a profound grasp of the tools involved is akin to navigating treacherous waters without a compass. The certified lifting sling is not merely a length of material; it is a piece of precision-engineered equipment, the silent partner in every successful and safe lift. Its function, while seemingly straightforward, is underpinned by complex principles of physics and material science. To treat it as a simple rope or chain is to invite disaster. Our first step, therefore, is to build a foundational understanding, to look beyond the surface and appreciate the intricate details that make these tools reliable.

What Differentiates a "Certified" Sling?

The term "certified" is not a marketing platitude. It is a declaration of compliance, a guarantee that the sling has been designed, manufactured, and tested in accordance with stringent standards. A non-certified sling is an unknown quantity; its capacity, its breaking strength, and its response to stress are all matters of dangerous speculation. A certified lifting sling, by contrast, comes with a pedigree.

This certification is typically validated against standards set by authoritative bodies. In the United States, the American Society of Mechanical Engineers (ASME) provides the B30.9 standard, which is the cornerstone for slings. In Europe, the Machinery Directive 2006/42/EC and associated EN 1492 standards for textile slings or EN 818 for chain slings are paramount. The International Organization for Standardization (ISO) also provides global benchmarks.

A manufacturer achieves this certification through a meticulous process. It involves specific material sourcing, controlled manufacturing procedures, and, most visibly, proof testing. Every certified lifting sling or a batch sample has been subjected to a load significantly higher than its stated capacity—typically twice the Working Load Limit (WLL)—without showing signs of deformation. This test serves as tangible proof that the sling can perform its duties safely within its prescribed limits. The certification is a pact of trust between the manufacturer and the user, a pact built on empirical evidence and a shared commitment to safety.

The Anatomy of a Sling: Materials and Construction

The choice of material is the first and most defining characteristic of a lifting sling. Each material possesses a unique constellation of properties, making it suitable for some tasks and dangerously inappropriate for others. The three primary families of materials are synthetic fabrics, wire rope, and alloy steel chain.

Synthetic Slings, which include both flat web slings and round slings, are typically made from polyester, nylon, or polypropylene. Think of them as the diplomats of the lifting world. Their soft, pliable nature makes them ideal for lifting objects with sensitive or easily marred surfaces, such as painted machine housings, polished stone, or composite boat hulls. Polyester is the most common, offering low stretch, good resistance to acids, and a high strength-to-weight ratio. Nylon, while stronger, has more stretch and is more susceptible to acidic environments, though it excels in its ability to absorb shock loads.

Wire Rope Slings are the industrial workhorses. Constructed from individual steel wires spun into strands, which are then wound around a core, they offer a good balance of strength, abrasion resistance, and flexibility. Their construction allows them to show early signs of distress through broken wires, providing a built-in warning system before failure. They are a common sight in construction and general manufacturing, lifting everything from steel beams to concrete panels. Their primary vulnerability is to crushing and kinking, which can permanently damage the internal wire structure.

Alloy Chain Slings represent the pinnacle of durability and ruggedness. Forged from special heat-treated steel alloys, they are the champions of high-temperature environments and applications where severe abrasion is expected. Foundries, steel mills, and heavy fabrication shops rely on chains for their ability to withstand the harshest conditions. Unlike other sling types, a chain sling's length can often be adjusted using specialized shortening clutches, adding a layer of versatility. Their main drawback is their immense weight and their unforgiving nature on delicate loads.

Understanding these fundamental differences is not an academic exercise. Selecting a polyester sling for a high-heat application or a chain sling for a polished marble slab represents a failure at this most basic step.

| Sling Type | Primary Material | Key Advantages | Common Applications | Primary Limitations |

|---|---|---|---|---|

| Synthetic Web Sling | Polyester, Nylon | Lightweight, flexible, protects delicate surfaces, cost-effective | General manufacturing, boat building, finished products | Low cut/abrasion resistance, susceptible to heat & UV damage |

| Synthetic Round Sling | Polyester | Highest flexibility, conforms perfectly to load, color-coded | Lifting irregular or sensitive shapes, high-capacity lifts | Low cut/abrasion resistance, internal damage hard to detect |

| Wire Rope Sling | Steel | Good strength, abrasion resistance, heat resistant | Construction, steel erection, general industry | Can kink or crush, heavy, can damage loads, wire breaks |

| Alloy Chain Sling | Heat-Treated Alloy Steel | Highest durability, high-temperature use, adjustable | Foundries, steel mills, harsh environments, machine shops | Very heavy, can damage loads, potential for brittle fracture if overloaded |

Decoding the Tag: Your First Line of Defense

If the sling's certification is its pedigree, the identification tag is its passport. This tag, permanently affixed to the sling, is the single most important source of information for the rigger. A sling with a missing or illegible tag must be immediately removed from service, no questions asked. The information it contains is not optional reading; it is the basis for every safe lift calculation.

According to the ASME B30.9 standard, the tag on a certified lifting sling must clearly state:

- Manufacturer's Name or Trademark: This establishes accountability. Knowing who made the sling, such as a reputable firm with a strong history in rigging solutions, provides an initial layer of confidence.

- Working Load Limit (WLL): The most vital piece of information. The WLL is the maximum mass or force which the sling is authorized to support in general lifting service. It is not the breaking strength.

- Rated Load for Different Hitch Types and Angles: The tag will often provide a chart showing how the sling's capacity changes with the type of hitch used (e.g., vertical, choker, basket) and the angle of the legs. We will explore this in greater detail, but the tag provides the authoritative numbers.

- Sling Material and Construction: It will specify whether the sling is polyester, wire rope (including its diameter and construction), or alloy chain (including its grade and size).

- Serial Number or Traceability Code: This unique identifier links the sling back to its specific manufacturing batch, allowing for traceability in case of a defect or recall.

To disregard the tag is to operate in blindness. It is the operator's responsibility to read, understand, and adhere to the limits and information it provides. It is the first and last word on the sling's capabilities.

Step 2: Assessing the Load and Environment

With a solid understanding of the tool itself, we must now turn our attention outward, to the object being lifted and the world it inhabits. A successful lift is a harmonious interaction between the sling, the load, and the environment. Misjudging any one of these elements can introduce forces and stresses that the system was not designed to handle. This step is about careful observation, calculation, and foresight. It is the intellectual core of the rigging process.

Calculating Load Weight and Center of Gravity

The first question must always be: "How much does it weigh?" An estimation is not sufficient. The exact weight of the load must be known, whether from shipping manifests, engineering drawings, or by using a calibrated load cell. This weight must then be compared directly to the Working Load Limit (WLL) of the certified lifting sling you plan to use. If the load's weight exceeds the WLL, the plan must stop and be re-evaluated. There is no acceptable margin for exceeding the WLL.

Equally significant is the load's center of gravity (CG). The CG is the point where the entire weight of the object can be considered to be concentrated. For a lift to be stable, the crane hook or lifting point must be positioned directly above the CG. If it is not, the load will tilt and swing as it is lifted, creating a wildly unpredictable and dangerous situation. For symmetrical objects like a steel cube, the CG is easy to find. For complex, asymmetrical objects, like a large motor with a heavy gearbox on one end, the CG will be offset. Riggers must analyze the object to determine its balance point, ensuring the lifting points are chosen to guarantee a level, stable lift.

The Profound Impact of Sling Angles on Capacity

Perhaps the most frequently misunderstood concept in rigging is the effect of sling angles. When you use two or more sling legs to lift a single object (a bridle hitch), the angle formed between the sling legs and the horizontal plane has a dramatic and non-intuitive effect on the tension within each sling leg.

Imagine holding a heavy grocery bag with one arm held straight down. Your arm feels the full weight of the bag. Now, imagine you and a friend carry a heavy box between you. If you stand close together, your arms are nearly vertical, and you each feel half the box's weight. But as you move farther apart, your arms extend outward at an angle. You will immediately feel the strain in your arms increase dramatically, even though the box's weight has not changed.

This same principle applies to certified lifting slings. As the angle between the sling and the horizontal decreases (i.e., the sling legs spread farther apart), the tension in each leg increases exponentially. A sling rated for 2,000 pounds in a vertical lift might be dangerously overloaded when lifting that same 2,000-pound object at a 30-degree angle.

This is not a matter of opinion; it is a matter of trigonometry. The tension in each sling leg is calculated by the formula:

Tension = (Load Weight / Number of Legs) / sin(Angle)

Where the "Angle" is the angle of the sling leg from the horizontal.

| Sling Angle (from Horizontal) | Load Multiplier (Increase in Tension) | Effective Capacity of a 1,000 kg Sling |

|---|---|---|

| 90° (Vertical Lift) | 1.000 | 1,000 kg |

| 60° | 1.155 | 866 kg |

| 45° | 1.414 | 707 kg |

| 30° | 2.000 | 500 kg |

| 15° | 3.864 | 259 kg |

As the table clearly illustrates, at a 30-degree angle, the tension on each sling leg is double what it would be in a simple vertical lift. The sling is working twice as hard. This is why sling tags provide reduced capacity ratings for angled lifts and why professional riggers carry angle indicators. An angle below 30 degrees is considered extremely hazardous and should be avoided in almost all situations. Ignoring the sling angle is one of the fastest routes to catastrophic sling failure.

Environmental Considerations: Temperature, Chemicals, and Abrasives

A certified lifting sling does not operate in a vacuum. The surrounding environment can be an aggressive adversary, degrading the sling's material and compromising its strength.

Temperature is a primary concern. Synthetic slings have a relatively narrow operating window. Most polyester and nylon slings should not be used in temperatures above 90°C (194°F) or below -40°C (-40°F). Extreme cold can make them brittle, while heat can cause irreversible softening and loss of strength. Wire rope slings are more tolerant of heat, but their capacity must be derated at very high temperatures. Alloy chain slings are the clear choice for high-heat environments like foundries, though even they have limits and can become brittle if improperly heat-treated or exposed to extreme cycles.

Chemical exposure is another silent killer. Synthetic slings are particularly vulnerable. Polyester offers good resistance to many acids, but it is degraded by alkalis. Nylon, conversely, is resistant to alkalis but is easily damaged by acids. Any chemical exposure, even from fumes, should be evaluated against the manufacturer's chemical resistance chart. Wire rope and chain can also be corroded by aggressive chemicals, leading to pitting and a reduction in their cross-sectional area, which directly reduces their strength.

Abrasives and Sharp Edges pose a direct physical threat. For synthetic slings, any contact with a sharp edge or rough surface is a critical danger. The material can be easily cut or abraded, leading to a sudden, total failure under load. Special cut-protection sleeves or pads must always be used to buffer the sling from any corner with a radius less than the sling's thickness. Wire rope is more abrasion-resistant but can be damaged by being dragged over rough surfaces, causing "bird-caging" or broken wires. Chains can be nicked or gouged, creating stress risers that can propagate into cracks.

Choosing the Right Hitch Type: Vertical, Choker, and Basket

The way a sling is attached to the load—the "hitch"—also fundamentally alters its lifting capacity.

-

Vertical Hitch: A single sling connects the lifting hook to a single attachment point on the load. The sling bears 100% of the load's weight, and its capacity is equal to its stated WLL. This is the simplest hitch but offers no load stability.

-

Choker Hitch: The sling is wrapped around the load and passed back through one of its own eyes. This creates a "choking" action that grips the load. While excellent for handling bundles of material like pipes or lumber, the sharp bend where the sling chokes causes a significant reduction in capacity, often to 75-80% of the vertical WLL. The angle of the choke also matters; a choke angle less than 120 degrees further reduces capacity.

-

Basket Hitch: The sling is passed under the load, and both eyes are attached to the lifting hook. In a true vertical basket hitch, the sling's capacity is doubled, as two legs are supporting the load. However, as soon as the legs spread and form an angle, the capacity must be derated according to the angle multiplier principle discussed previously. A basket hitch provides excellent load support and stability.

The choice of hitch is a tactical decision based on the load's shape, the presence of attachment points, and the need for stability. The rigger must consult the sling's tag to confirm the specific WLL for the chosen hitch configuration.

Step 3: Selecting the Appropriate Certified Lifting Sling

With a thorough assessment of the load and environment complete, the process of selection can begin. This is not like choosing a tool from a toolbox based on convenience. It is a deliberative process of matching a specific, certified lifting sling to the unique demands of the task at hand. The wrong choice can lead to equipment damage, load damage, and, most severely, human injury. The right choice ensures efficiency, safety, and peace of mind.

Synthetic Web and Round Slings: For Delicate Surfaces

When the object being lifted is as valuable as the lift itself, synthetic slings are often the premier choice. Consider the task of lifting a multi-million-dollar composite yacht hull or a precision-machined aluminum aircraft wing. The use of a wire rope or chain sling would be unthinkable, as it would inevitably scratch, gouge, or dent the pristine surface.

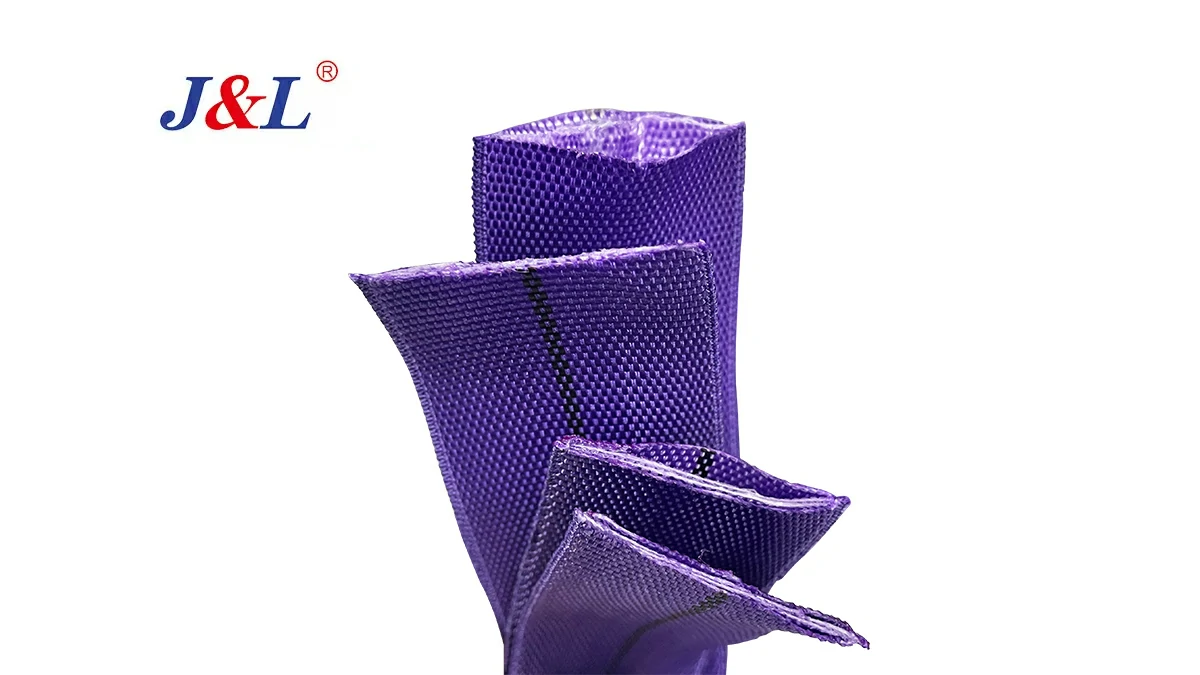

This is the domain of our range of textile slings. Web slings, with their broad, flat surface, distribute the load's pressure over a wider area, minimizing the risk of damage. They are lightweight, easy to handle, and their flexibility allows them to conform to the shape of the load. Round slings, which consist of a continuous loop of polyester fibers encased in a protective cover, offer even greater flexibility and can be used in all hitch types. Their construction provides a very high strength-to-weight ratio, and their soft exterior is exceptionally gentle on sensitive loads.

However, their delicacy is a double-edged sword. Their greatest strength is also their greatest vulnerability. They must be zealously protected from sharp corners, abrasive surfaces, welding slag, and prolonged UV exposure from sunlight, which can degrade the fibers over time. They are the specialists of the sling world, performing their specific task with unparalleled finesse but requiring careful handling and protection.

Wire Rope Slings: The Workhorse for Abrasive Loads

In the rugged world of construction sites and industrial yards, where loads are often made of concrete, steel, and other unforgiving materials, the wire rope sling reigns supreme. Its steel construction gives it an inherent resistance to abrasion and cutting that synthetic slings lack. Lifting a bundle of rebar or a rough-hewn granite block with a wire rope sling is standard practice.

The design of a wire rope sling is a marvel of engineering. The multiple wires and strands create a redundant system. The failure of a single wire does not mean the immediate failure of the sling; instead, it serves as a visible warning sign during inspection that the sling is wearing out and approaching the end of its service life. This "tell-tale" nature is a significant safety feature.

They are also more tolerant of higher temperatures than synthetics, making them suitable for a broader range of industrial environments. Their primary drawbacks are their weight, their relative lack of flexibility, and their tendency to leave grease or marks on cleaner loads. Kinking, crushing (for example, by driving a forklift over it), and corrosion are its main enemies. When durability and abrasion resistance are the top priorities, wire rope is often the most logical and safest choice. A wide array of these, alongside other essentials like shackles and elevator links, form the backbone of heavy lifting.

Alloy Chain Slings: For High-Temperature and Rugged Use

When the operational environment becomes truly hostile, the alloy chain sling comes into its own. In a steel foundry where ambient temperatures can be extreme, or in a galvanizing plant with chemical fumes, synthetic and even wire rope slings would have a very short and dangerous life. Alloy chain slings, forged from Grade 80, Grade 100, or even stronger alloys, are built for these extremes.

Their durability is unmatched. They can withstand the intense heat, sparks, and chemical exposures that would destroy other materials. They are also incredibly resistant to cuts and abrasion. A sharp steel edge that would instantly sever a synthetic sling might only leave a minor nick on a chain link. Furthermore, high-quality chain slings are often repairable by competent personnel, with damaged links or components being replaced to restore the sling to full service—a feature unique among sling types.

The trade-offs are significant. Chain slings are by far the heaviest type, making them more difficult to handle and rig. Their hardness means they will damage any load that is not equally hard. Their lack of flexibility can be a challenge with irregularly shaped loads. Their use demands a commitment to regular, thorough inspection, as a small crack in a single link, invisible to the untrained eye, can be a harbinger of sudden, brittle failure under load. For the toughest jobs in the toughest places, however, there is no substitute for the raw strength of alloy chains.

Matching the Sling to the Application: Case Studies

Let's consider three scenarios to illustrate the selection process:

-

Case Study 1: Lifting a Marble Statue. The load is heavy, uniquely shaped, and has a highly polished, irreplaceable surface. The weight is known, and the environment is a controlled indoor museum setting. The only logical choice is a synthetic sling, likely a pair of polyester round slings used in a basket hitch. Their flexibility will allow them to conform to the statue's curves, and their soft surface will prevent any scratching. Cut protection would be used at any point where the sling passes over a sharp change in contour.

-

Case Study 2: Unloading Steel I-Beams from a Truck. The load consists of multiple heavy, long beams with rough, sharp edges. The environment is an outdoor construction site, possibly muddy or dusty. Here, a set of wire rope slings used in a bridle hitch would be ideal. They can withstand the abrasion from the steel, and their strength is well-suited to the heavy load. The use of a spreader beam might be required to ensure the sling angles remain favorable (above 60 degrees).

-

Case Study 3: Placing a Mold in a Forging Press. The load is a heavy steel mold that must be lowered into a press that is still hot from previous operations. The environment is filled with heat, and there is a risk of contact with hot surfaces. An alloy chain sling is the only safe option. Its ability to withstand high temperatures makes it uniquely qualified for this task. A synthetic or wire rope sling would fail, likely catastrophically.

Considering the Safety Factor: Beyond the Working Load Limit

The Working Load Limit (WLL) is the headline number, but behind it lies another critical concept: the Design Factor, or Safety Factor. The Safety Factor is the ratio between the sling's minimum breaking strength (MBS) and its WLL.

Safety Factor = Minimum Breaking Strength (MBS) / Working Load Limit (WLL)

For example, a synthetic lifting sling with a WLL of 2,000 pounds and a 5:1 safety factor has a minimum breaking strength of 10,000 pounds. This does not mean it is safe to lift 9,000 pounds with it. The WLL is the absolute maximum. The safety factor exists to provide a buffer against unforeseen circumstances, such as moderate shock loading, minor undetected wear, or slight variations in material strength. It is a margin for error, not an invitation to overload.

Different sling types have different standard safety factors, reflecting their material properties and failure modes.

- Synthetic Slings (Web and Round): Typically have a 5:1 safety factor.

- Wire Rope Slings: Typically have a 5:1 safety factor.

- Alloy Chain Slings: Typically have a 4:1 safety factor.

A higher safety factor generally indicates a material that is more susceptible to degradation from wear, UV light, or other environmental factors. The larger margin is necessary to account for this potential loss of strength over the sling's service life. Understanding this concept reinforces why the WLL must be treated as an inviolable limit. It has already been carefully calculated by the manufacturer, like a leading manufacturer of rigging solutions, to provide a safe working capacity while retaining a crucial safety margin.

Step 4: The Rigorous Inspection Protocol

A certified lifting sling begins its life in a state of verified perfection. From the moment it is put into service, however, it begins a slow journey of degradation. Every lift, every bit of friction, every exposure to sunlight or a sharp edge contributes to its wear. The purpose of an inspection protocol is to monitor this journey, to identify signs of damage or wear, and to remove the sling from service long before its strength is compromised to a dangerous degree. Inspection is not a bureaucratic chore; it is an active, ongoing process of risk management.

The Three Tiers of Inspection: Initial, Frequent, and Periodic

A comprehensive safety program relies on a multi-layered inspection strategy, as outlined by standards like OSHA 1910.184 and ASME B30.9.

-

Initial Inspection: Before a brand-new or newly repaired sling is ever used, it must be inspected by a designated person to ensure it is the correct sling for the job and that it has not been damaged in transit. This inspection also confirms that the sling's identification tag matches the specifications on the purchase order and test certificate.

-

Frequent Inspection: This is the inspection that happens before every shift or before each use. It is a hands-on, visual examination performed by the operator or rigger who will be using the sling. The goal is to catch obvious, new damage that may have occurred during the previous lift. This is the most effective way to prevent an accident caused by a recently damaged sling. It is a quick but vital check of the sling's immediate fitness for duty.

-

Periodic Inspection: This is a more formal and thorough inspection, which must be documented with a written record. The frequency depends on the sling's usage. For slings in normal service, it is typically performed annually. For slings in severe service (e.g., in harsh chemical or abrasive environments) or those used more frequently, the inspection interval might be monthly or quarterly. Periodic inspections must be conducted by a "qualified person"—someone who, by possession of a recognized degree or certificate and extensive knowledge, training, and experience, has successfully demonstrated the ability to solve problems relating to the subject matter.

Visual Inspection Checklist: What to Look For Before Every Lift

The frequent, pre-use inspection is a sensory experience. It involves looking and feeling along the entire length of the sling. While specific criteria vary by sling type, the rigger is searching for any deviation from the norm.

For Synthetic Web and Round Slings:

- Cuts, Snags, or Tears: Any cut on the surface or at the edges is a major red flag.

- Broken or Worn Stitching: The stitching patterns hold the sling together; any sign of unraveling or abrasion compromises the sling's integrity.

- Heat or Chemical Damage: Look for melted, charred, or discolored areas, which indicate a loss of strength.

- Knots: A knot in a synthetic sling can reduce its strength by as much as 50%. Any sling with a knot must be removed from service.

- Excessive Abrasion: A fuzzy or frayed appearance indicates surface wear that has weakened the fibers.

- Illegible Tag: If you cannot read the WLL, the sling is unusable.

- For Round Slings: Feel for gaps or a loss of core yarn, which would indicate internal damage.

For Wire Rope Slings:

- Broken Wires: The number of acceptable broken wires in a given area is specified by ASME B30.9. As a general rule, more than 5 broken wires in one strand or 10 in the whole rope is cause for removal.

- Kinking, Crushing, or "Bird Caging": These are signs of severe physical damage that distort the rope's structure.

- Heat Damage: Discoloration or melted areas indicate the rope has been exposed to excessive heat.

- Corrosion: Severe rust pits the wires and reduces their diameter and strength.

- Reduced Rope Diameter: A noticeable "necking down" of the rope indicates internal core failure or excessive external wear.

For Alloy Chain Slings:

- Nicks, Gouges, or Cracks: Run a hand (carefully) along each link. Any sharp indentation creates a stress riser that can lead to failure.

- Stretched Links: Visually compare links. Any link that appears longer or narrower than the others has been overloaded.

- Wear or Corrosion: A reduction in the diameter of the chain material by more than the amount specified by the manufacturer (often 10-15%) is cause for removal.

- Bends or Twists: Each link should be perfectly formed; any distortion is a sign of damage.

Documenting Inspections for Compliance and Safety Records

While frequent inspections are typically mental checks, periodic inspections demand a formal, written record for each individual sling, identified by its serial number. This documentation is a legal and safety requirement in many jurisdictions.

The record should include:

- The unique serial number of the sling.

- The date of the inspection.

- The name of the qualified person who performed the inspection.

- A description of the condition of the sling, noting any damage or wear.

- A final determination: Pass or Fail.

These records serve multiple purposes. They provide a clear history of the sling's condition over time, allowing for better prediction of its remaining service life. They demonstrate regulatory compliance to safety inspectors from bodies like OSHA. Most importantly, they create a formal system of accountability that ensures inspections are not overlooked. Maintaining these records is a core part of demonstrating our commitment to safety.

Criteria for Immediate Removal from Service

The inspection process culminates in a simple, binary decision: is this sling safe to use, or must it be removed from service? There is no middle ground. A sling that is "a little bit damaged" is a sling that has an unknown capacity and an unacceptable risk profile.

Any sling that meets the rejection criteria—be it a cut in a web sling, excessive broken wires in a wire rope, or a stretched link in a chain—must be immediately removed from the work area. To prevent accidental reuse, it should be tagged as "Out of Service" and either destroyed or sent to the manufacturer for evaluation and potential repair. Destroying a failed sling often involves cutting it into pieces to make it impossible to use. This final act ensures that a known hazard is permanently eliminated from the workplace.

Step 5: Mastering Safe Use and Proper Storage

Possessing a correctly selected and thoroughly inspected certified lifting sling is only part of the equation. The final step is to use it with skill, respect, and an unwavering focus on safe practices. Even the best equipment can be rendered dangerous by improper handling. This step covers the dynamic phase of the lift itself, as well as the often-neglected but equally vital practice of proper storage, which ensures the sling is ready and safe for its next task.

Pre-Lift Safety Briefings and Communication

No lift, especially a complex one, should begin without a plan and clear communication. Before the load is tensioned, the entire lift team—the crane operator, the rigger, and any signalpersons or spotters—should conduct a pre-lift briefing or "toolbox talk."

This briefing should cover:

- The weight of the load.

- The chosen lifting points and hitch type.

- The path of the lift, including any obstacles.

- The designated landing zone.

- The communication signals to be used (standard hand signals are preferred).

- The roles and responsibilities of each team member.

- Any specific environmental hazards (e.g., wind, proximity to power lines).

This meeting ensures everyone is on the same page and working from the same plan. It is also the final opportunity for any team member to voice a concern if they see something unsafe. A culture where anyone can stop the job if they feel it is unsafe is a hallmark of a mature safety program.

Techniques for Protecting Slings from Damage

During the lift, the rigger's primary responsibility is to protect the certified lifting sling from damage. The most common cause of synthetic sling failure is cutting. Therefore, the use of edge protection is not optional; it is mandatory whenever a sling comes into contact with a corner or edge. This protection can take the form of specialized high-performance fabric sleeves, magnetic rubber protectors, or even wooden blocking. The goal is to soften the corner, increasing the radius the sling bends over and preventing the sharp edge from concentrating stress on the fibers.

For all sling types, it is vital to ensure the sling is seated correctly in the hook and on the load. The sling should not be twisted, knotted, or bunched up. In a basket hitch, the load should be balanced to prevent it from slipping. When using multi-leg bridle slings, the attachment points should be chosen to equalize the load on each leg as much as possible.

Avoiding Shock Loading and Overloading

The Working Load Limit is based on a slow, steady application of force. Any sudden starts, stops, or impacts create a "shock load," a dynamic force that can be many times greater than the static weight of the object. Dropping a load a few inches and having the sling suddenly catch it can easily exceed the sling's breaking strength, not just its WLL. Crane movements should be smooth and deliberate. The operator must lift the load gently, without jerking, and lower it in the same controlled manner.

Overloading, even without shock, is a cardinal sin of rigging. It occurs when the load's weight exceeds the sling's rated capacity for the specific hitch and angle being used. It is a direct result of poor planning—either miscalculating the load weight or failing to account for the tension increase caused by sling angles. Both shock loading and overloading can cause immediate, catastrophic failure, or they can cause hidden damage (like a stretched chain link) that leads to failure on a subsequent, seemingly normal lift. The use of other rigging hardware, like ratchet straps for securing loads post-lift or mooring ropes in maritime settings, also requires a similar respect for load limits.

Proper Storage Practices to Maximize Sling Lifespan

The life of a certified lifting sling does not end when the load is set down. How it is stored between uses has a profound impact on its longevity and safety. A sling left on the ground can be run over by vehicles, exposed to moisture and dirt, or damaged by chemicals. A sling left hanging in direct sunlight will suffer from UV degradation.

The ideal storage area for lifting slings is clean, dry, and well-ventilated. Slings should be hung on dedicated racks that do not have sharp edges or protrusions.

- Synthetic slings should be stored away from sunlight and any sources of UV radiation, as well as away from heat sources and chemical storage areas.

- Wire rope slings should be lightly lubricated according to the manufacturer's recommendations to prevent corrosion and stored off the ground.

- Chain slings should also be hung to prevent tangling and corrosion and to allow for easy visual inspection.

By taking the time to store slings properly, an organization protects its investment and ensures that when a rigger reaches for a sling, they are starting with a clean, undamaged, and safe piece of equipment. This discipline completes the cycle of safety, connecting the end of one lift to the beginning of the next.

Frequently Asked Questions (FAQ)

What is the difference between Working Load Limit (WLL) and Minimum Breaking Strength (MBS)? The Working Load Limit (WLL) is the maximum load a sling is certified to lift in general service. The Minimum Breaking Strength (MBS) is the force at which the sling is expected to fail. The WLL is determined by dividing the MBS by a safety factor (e.g., 5:1). You must never exceed the WLL.

How often do certified lifting slings need to be inspected? Slings require three types of inspection: an initial inspection before first use, a frequent inspection by the user before each lift, and a documented periodic inspection by a qualified person at regular intervals (typically annually, but more often for severe service).

Can I repair a damaged lifting sling? Generally, synthetic and wire rope slings should not be repaired; they should be destroyed. Some alloy chain slings can be repaired by replacing damaged components, but this must only be done by the manufacturer or a similarly qualified entity in strict accordance with their procedures.

What does the color of a synthetic sling mean? For polyester web slings, the color often indicates the sling's capacity. For example, purple may indicate a 1-ton vertical WLL, green a 2-ton WLL, and so on. However, this color code is not universal across all manufacturers. For round slings, the color of the cover indicates the WLL, and this code is standardized by EN 1492-2 and other regulations. You must always confirm the capacity by reading the tag, not by relying on color alone.

How does the sling angle affect its lifting capacity? As the angle between the sling and the horizontal decreases (the legs spread apart), the tension in each sling leg increases dramatically. A sling used at a 30-degree angle will experience twice the tension as a sling in a vertical lift. This effect significantly reduces the effective lifting capacity of the sling.

What are the main standards for lifting slings in 2025? The primary standards are ASME B30.9 in North America, the EN 1492 series (for textile) and EN 818 series (for chain) in Europe under the Machinery Directive, and various ISO standards globally. These define manufacturing, testing, inspection, and usage requirements.

How do I clean my lifting slings? Synthetic slings can be cleaned with a solution of mild soap and water. They should be air-dried away from direct sunlight or heat. Never use harsh industrial solvents. Wire rope and chain slings can be wiped down to remove dirt and grit, and re-lubricated as needed to prevent corrosion.

Conclusion

The responsible use of certified lifting slings is a discipline grounded in knowledge, diligence, and respect for the forces involved. It is a field where shortcuts have severe consequences and where adherence to procedure is the bedrock of safety. From understanding the nuanced language of a certification tag to calculating the subtle yet powerful effects of a sling angle, each step in the process is a critical link in a chain of safety. The selection of the correct material—be it the gentle strength of synthetic, the rugged reliability of wire rope, or the sheer fortitude of alloy chain—must be a deliberate choice based on a careful analysis of the load and its environment.

This process is continuous, extending through the rigorous, multi-tiered inspection protocols that monitor the health of the sling throughout its service life and culminating in the skilled, safe application and proper storage of the tool. In an industry where the margin for error is vanishingly small, a deep and practical understanding of these principles is not just a matter of professional competence; it is a moral obligation to protect lives, property, and the operational integrity of the entire endeavor. The certified lifting sling is more than just equipment; it is a commitment to getting the job done safely.

References

Lashinglift. (2024). How to calculate load on a web sling: A comprehensive guide. Lashinglift. https://lashinglift.com/how-to-calculate-load-on-a-web-sling-a-comprehensive-guide/

Lieying Group Technology Department. (2025). Webbing sling safety factor: A complete guide to safe lifting and why it matters. Lieying Rigging. https://www.lieyingrigging.com/blogs/webbing-sling-safety-factor.html

Juli Sling. (2025). Why is WLL of lifting sling important, and what does it mean? Juli Sling. https://www.julislings.com/blog/why-is-wll-of-lifting-sling-important,-and-what-does-it-mean.html

American Society of Mechanical Engineers. (2021). ASME B30.9-2021: Slings. ASME. https://www.asme.org/codes-standards/find-codes-standards/b30-9-slings

Occupational Safety and Health Administration. (n.d.). 1910.184 – Slings. U.S. Department of Labor. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.184

Lifting Equipment Engineers Association. (n.d.). LEEA standards. LEEA. https://leeaint.com/leea-standards

HSE. (n.d.). Lifting equipment. Health and Safety Executive. https://www.hse.gov.uk/work-equipment-machinery/lifting-equipment.htm

Liftingsling.com. (2023). The complete guide on using lifting slings. https://www.liftingsling.com/blogs/the-complete-guide-on-using-lifting-slings