Why Do Construction and Mining Projects Rely on Compacted Strand Wire Rope?

August 18, 2025

In the demanding worlds of construction and mining, reliability and strength are non-negotiable. From lifting massive loads to withstanding abrasive conditions, equipment must deliver consistent performance under extreme stress. One material that has become indispensable in these industries is the compacted strand wire rope. Known for its superior strength, reduced stretch, and enhanced resistance to wear, it provides a level of reliability that standard wire ropes cannot match.

The Technology Behind Compacted Wire Rope

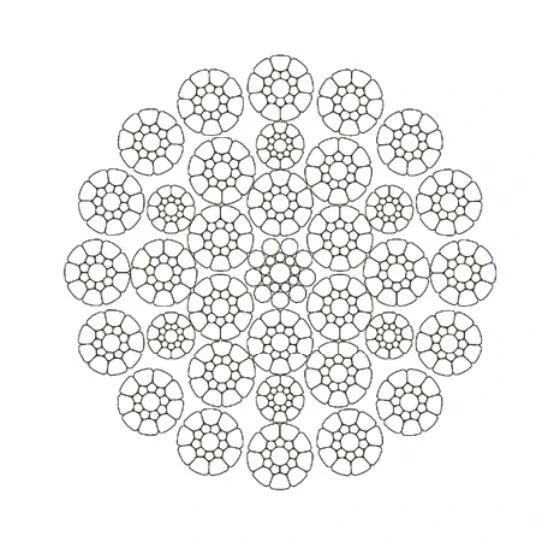

A compacted strand wire rope is manufactured by compressing strands through a die, which reduces the overall diameter while increasing density. This process strengthens the rope, giving it a smoother surface and greater load-bearing capacity. Compared to conventional ropes, compacted wire rope offers higher breaking strength and greater fatigue resistance, which are crucial for heavy-duty applications.

The smoother exterior also helps minimize abrasion between the rope and pulleys, leading to a longer lifespan. For industries where downtime can result in significant losses, this durability is a major advantage.

Why It Matters in Construction

On construction sites, efficiency and safety are the highest priorities. Tower cranes, hoists, and heavy lifting equipment rely on ropes that can endure repeated stress without stretching or fraying. Compacted strand wire ropes are ideal for these applications because:

- They handle higher loads with smaller diameters, reducing equipment weight.

- Their improved wear resistance extends operational life.

- Lower elongation ensures stability and safety when lifting heavy materials.

By providing superior performance, these ropes help construction companies achieve greater productivity while reducing replacement and maintenance costs.

The Role in Mining Operations

Mining is one of the harshest environments for lifting and hauling equipment. Wire ropes are constantly exposed to abrasive rock, dirt, and extreme mechanical stress. In this setting, the advantages of compacted wire rope are clear:

- Higher resistance to crushing and bending fatigue.

- Reduced internal wear due to compacted structure.

- Longer service intervals, which minimizes downtime in critical operations.

For underground hoisting systems, draglines, and mine winders, compacted ropes are often the only viable choice for ensuring continuous and safe operation.

Comparing with Other Lifting Solutions

While compacted strand wire ropes are widely used, other lifting materials also play a role. For example, webbing sling types provide flexible lifting solutions in environments where wire rope might be too rigid or abrasive for delicate loads. Webbing slings are lightweight, easy to handle, and ideal for situations where precision and load protection are key.

However, for extreme loads and harsh conditions, compacted ropes remain unmatched. Many operators choose to integrate both solutions—using webbing slings for lighter or sensitive lifts while relying on compacted strand wire ropes for heavy-duty operations.

Juli Sling: A Trusted Partner in Lifting Solutions

For companies seeking reliability and innovation, Juli Sling has become a global leader in lifting and rigging products. The company specializes in a wide range of lifting equipment, including compacted strand wire ropes, compacted wire ropes, and webbing sling types.

Juli Sling’s success is built on advanced manufacturing processes, strict quality control, and a commitment to meeting international safety standards. By offering customized solutions, the company ensures that construction and mining operators can find the exact rope or sling for their unique challenges.

Looking Ahead

As projects grow in scale and complexity, demand for high-performance lifting solutions will continue to rise. Compacted strand wire ropes are set to remain at the core of this demand, offering the durability, efficiency, and safety needed in modern industries.

With Juli Sling’s expertise and global reputation, companies can access lifting products that are not only reliable but also engineered for long-term performance. From high-rise construction to deep mining operations, compacted wire ropes deliver the strength that keeps projects moving forward.

Rely on Juli Sling for Your Lifting Needs

For uncompromising strength and durability, choose compacted strand wire ropes, compacted wire ropes, and versatile webbing sling types from Juli Sling. Contact Juli Sling today and discover lifting solutions that redefine safety and efficiency in construction and mining.