Wire Rope Sling

Description

1. Steel wire rope sling products: Marine engineering series(grommet sling, high tension grommet sling, cable-laid sling), construction engineering series(pressed and casting sling), hoisting engineering series(pressed and spliced sling) and specialized sling.

2. Production diameter range: 6mm-570mm.

3. Possess the largest 10,000T pressing machine, and it can be the largest one in Asia market. Several heavy duty equipment have got the patent for inventing, including: horizontal turning grommet sling machine, horizontal vertical grommet sling machine and large-scaled horizontal steel cable splicing machine, etc.

Our Advantages

1. High performance cable sling is manufactured through special splicing process by JULl independently researched and produced professional equipment.

2. Depending on the different working place, we should chose the rope with different surface treated, includingl galvanized wire rope with lubrication. gal anized wire rope without lubr cation and un-galvanized, total three choices.

3. Be able to bear multiple loads and variable loads.

4. High tensile strength, fatigue strength and impact toughness.

5. Good corrosion resistance and can work normally in the harsh environment of various harmful media.

6. We have awarded several leading international science & technology achievements and many national invention patents. And compiled state standards<General used wire rope sling characteristics and technical conditions> GB/T 16762-2009, <The wire rope sling-Grommet sling> GB/T30587-2014, <Wire rope sling end - Alloy casting socket> GB/T30588-2014. And have participated in compiling state standards <The wire rope sling - splicing sling> GB/T 16271-2009, <Wire rope sling end-sleeved pressing sling >GB/T30589-2014, etc.

Applications

Discover the limitless applications of our wire rope slings. Their robust construction makes them the go-to solution for lifting or securing objects with precision. Whether it's heavy loads in construction or delicate handling in manufacturing, these slings provide unparalleled versatility and adaptability.

Our wire rope slings are designed to withstand heavy loads and demanding conditions, making them ideal for a diverse range of lifting operations. Whether you need single-leg slings, multi-leg slings, or specialized slings for specific purposes, Juli Sling has you covered. We offer a comprehensive range of wire rope slings crafted from high-quality materials to ensure strength, durability, and long-lasting performance. It is widely used in a variety of lifting, hoisting, and traction equipment. Also the metallurgical machinery construction field. Such as cranes, construction machinery, shaft lifting, inclined shaft lifting, port loading and unloading, shipbuilding, transportation, mining industry, petroleum, marine engineering, etc.

Specifications

| Gromment Sling | ||

|

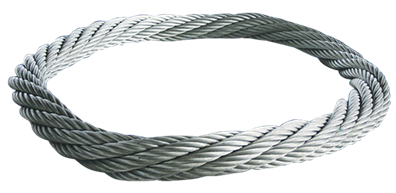

Grommet sling is machined through special process by JULI independently researched and produced professional equipment. Theequipment has got the national patent (Patent No.ZL2005 2 014 1834.0) Size available: 10mm to 570mm | |

| In the form, grommet sling was spliced by the wire rope with the characters of class b or ab, fiber core, nominal tensile strengthl 1670MPa. Depending on the different working place, we should chose the rope with different surface treated, including galvanized wire rope with lubrication, galvanized wire rope without lubrication and un-galvanized, total three choices. | ||

| Choose different capability wire rope to splice the grommet sling, its breaking load is different. Shall calculate the sling's breakingl strength according to the steel wire rope construction. | ||

| Min Breaking load of grommet sling is 5 times of that working load. According to the requirements of the industry, other safety factorsl also can be applied. The safety factory of the following operation can be executed with the standard <The wire rope sling -grommet sling> GB/T30587-2014, such as the load weight is accurate calculated or measured, hoist operation is to be monitored and controlled and dynamic coefficient are limited. The same, when the diameter is 60mm or less than, take the safe factor of 5, the diameter from 60 to 150 mm take the safety factor of(6.31-0.022D), when the diameter is greater than 150 mm, safety factor should not be less than 3. | ||

| Special for limited space lifting, the shortest sling circumference should be 50 times of sling diameter. | ||

| The min, bend radius of the lifting point area should not be less than 1.5 Dia. | ||

| The angle in the form is the diagonal angle. | ||

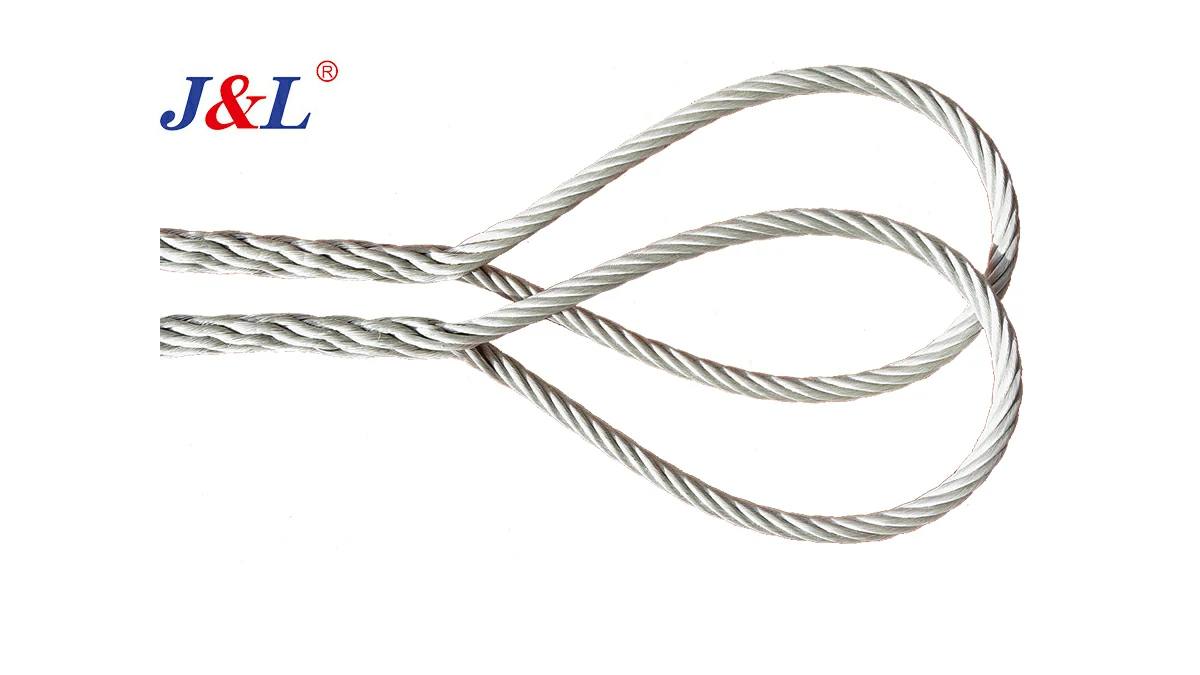

| Nine-Strand Steel Wire Rope Sling | ||

|

The nine-strand sling is very different from the normal slings, it remove the effect from the cable core to cable bending radius. Production range: 40mm to 320mm | |

| Enwinding uniformly steel cable and tiered construction eye enhance the loading weight of the sling, under the condition of the sametonnage, the self-weight of the sling is more lower than others. And the length shall be much shorter. | ||

| In addition, the eye parts was treated by special way, it lengthen the usage life to a great extent. | ||

| Steel Cable Splicing Sling | ||

|

High performance cable sling is manufactured through special splicing process by JuLl independently researched and producedl professional equipment. Size available: 100mm to 500mm. | |

| Both eye parts are specially processed to extend its service life. | ||

| The minimum bend radius of the lifting point area should not be less than 1.5d. | ||

| In the form, steel cable sling was spliced by the wire rope with the characters of class a or ab, steel core, nominal tensile strengthl 1770MPa. Depending on the different working place, we should chose the rope with different surface treated, including galvanized wire rone with lubrication galvanized wire rone without lubrication and un-galvanized total three choices | ||

| When using much higher tensile strength wire rope to splice the grommet sling, the rope diameter should be smaller than the normal tension strength rope. | ||

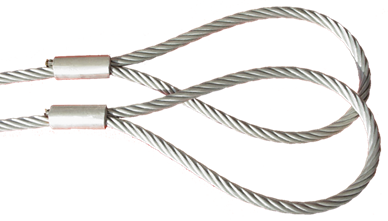

| Pressed Steel Wire Rope Sling | ||

|

This specification of the wire rope used for the working load: from 6mm to 60mm with construction 6x37type b-1670 | |

| Different construction of the rope means different working load, we can calculate the working load according with the steel wire rope construction which the customer required. | ||

| The sling's breaking load is 5 times of the working load. | ||

| When the wire rope diameter is up to 90mm, should be pressed two aluminum alloy joints on each end of sling. | ||

| We use one aluminum ferrule painted with the blue color as the quality ID of Juli Sling. | ||

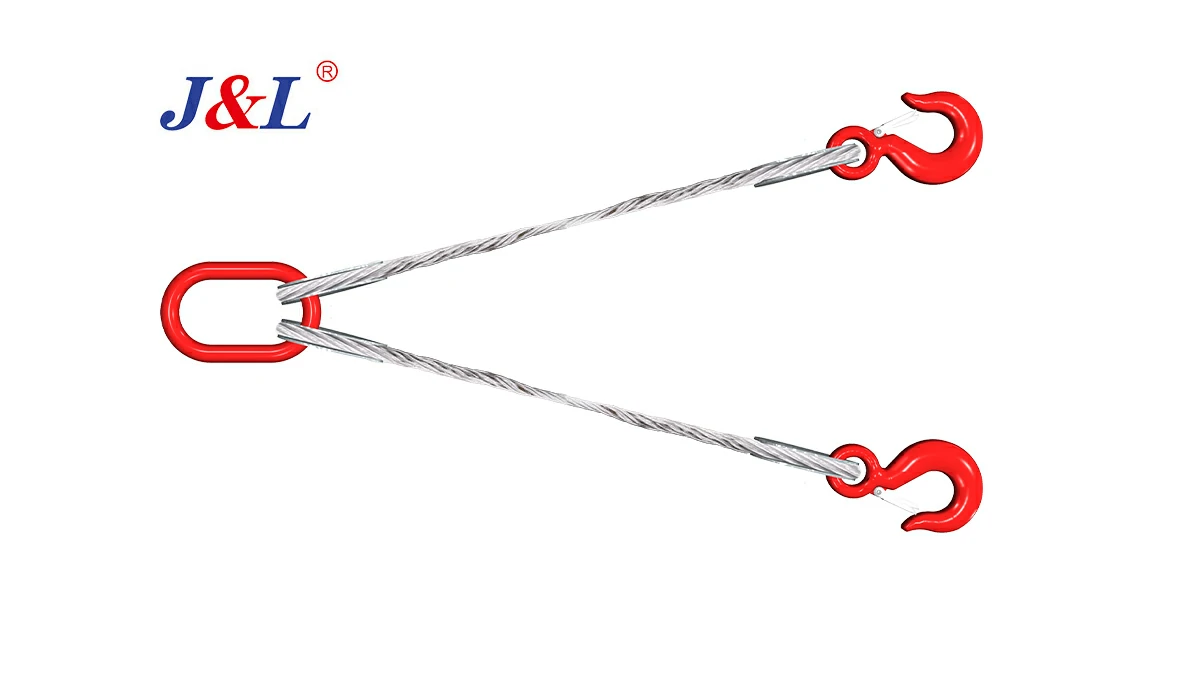

| Double Leg Pressed Steel Wire Rope Sling | ||

|

The specification of the wire rope in the form is 6x37+FC-1670. | |

| This form with two status working load. The 0°-90°is the priority if the customers without any special requirement. | ||

| Different construction rope with different working load, we can calculate the workingload according with the steel wire rope construction which the customer required. | ||

| Both ends of fittings with safety factor 4, and other parts safety factor is 5. | ||

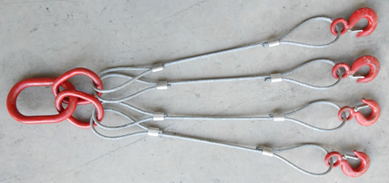

| Four Legs Pressed Steel Wire Rope Sling | ||

|

The specification of the wire rope in the form is 6x37+FC-1670. | |

| This form with two status working load. The 0°-45°is the priority if the customers without any special requirement. | ||

| Different construction rope with different working load, we can calculate the working load according with the steel wire rope construction which the customer required. | ||

| Both ends of fittings with safety factor 4, and other parts safety factor is 5. | ||

| Single-Stranded Cable | ||

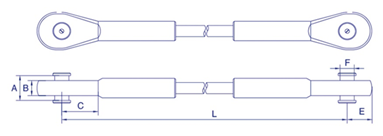

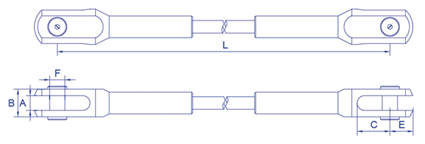

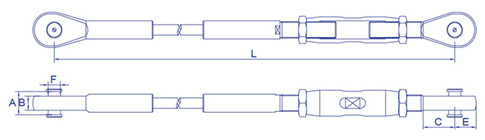

| O Type Pressed Single-Stranded Cable | U Type Pressed Single-Stranded Cable | OT Type Pressed Single-Stranded Cable |

|

|

|

Custom Wire Rope Slings Tailored to Your Needs

At Juli Sling, we understand that each lifting application has unique requirements. That's why we offer custom wire rope slings tailored to meet your specific needs. Our experienced team works closely with you to understand your lifting challenges and design wire rope slings that provide optimal safety and efficiency. With our custom solutions, you can have confidence in the performance and reliability of your lifting equipment.

Capacity and Breaking Strength: Tailor your rigging solutions by determining the required capacity or breaking strength. Our wire rope slings offer varying diameters to match your lifting tasks.

Number of Legs and Length: From single-leg to four-leg configurations, our slings adapt to the intricacies of your operation. Choose the ideal length of each leg for seamless integration into your rigging setup.

End Fittings and Terminations: Elevate your lifting game by selecting the perfect end fittings for each leg. Whether it's reinforced eyelets, spring latch hooks, self-locking hooks, or shackles, our slings offer a range of options to suit your preferences.

Reliable and Safe Lifting Solutions

Safety is our top priority at Juli Sling. Our wire rope slings undergo rigorous quality control processes to ensure they meet or exceed industry standards. We utilize advanced manufacturing techniques and select high-quality materials to create wire rope slings that offer exceptional resistance to abrasion, corrosion, and wear. Trust our reliable and safe lifting solutions to protect your personnel and assets during lifting operations.

Expert Guidance and Support

Choosing the right wire rope sling can be challenging. At Juli Sling, our team of experts is here to guide you through the selection process. We provide comprehensive support, sharing our knowledge and expertise to help you make informed decisions. Whether you have questions about sling configurations, load capacities, or industry regulations, we are dedicated to ensuring you have the right wire rope sling for your specific lifting requirements.

Partner with Juli Sling for Your Wire Rope Sling Needs

When it comes to wire rope slings, Juli Sling is your trusted partner. We combine quality craftsmanship, technical expertise, and exceptional customer service to deliver reliable lifting solutions. Whether you need wire rope slings for construction, manufacturing, offshore, or any other industry, we have the products and expertise to meet your needs. Experience the difference with Juli Sling as your wire rope sling supplier.

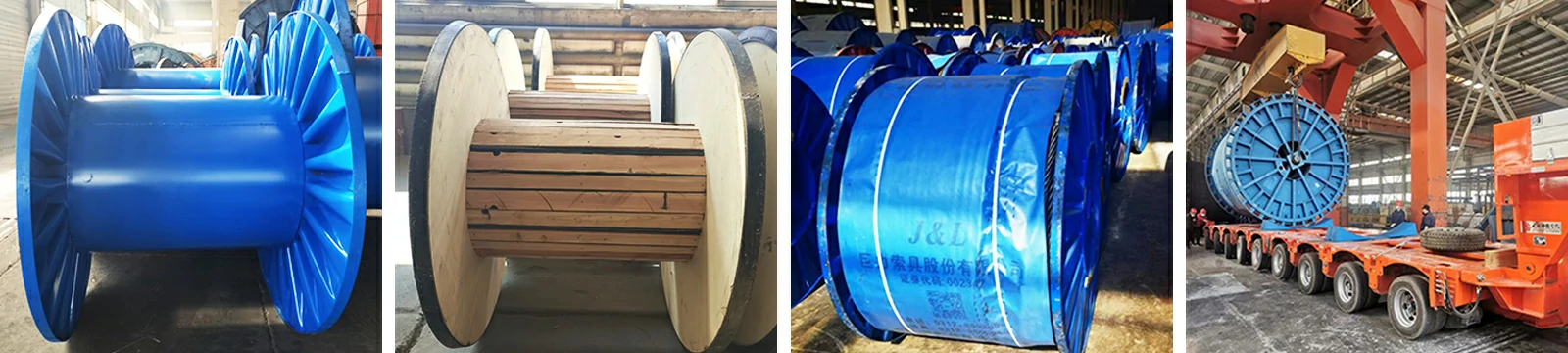

Package

JULI standard export package: Wooden Reel / Steel Wheel Reel

Customized packaging according to customer needs

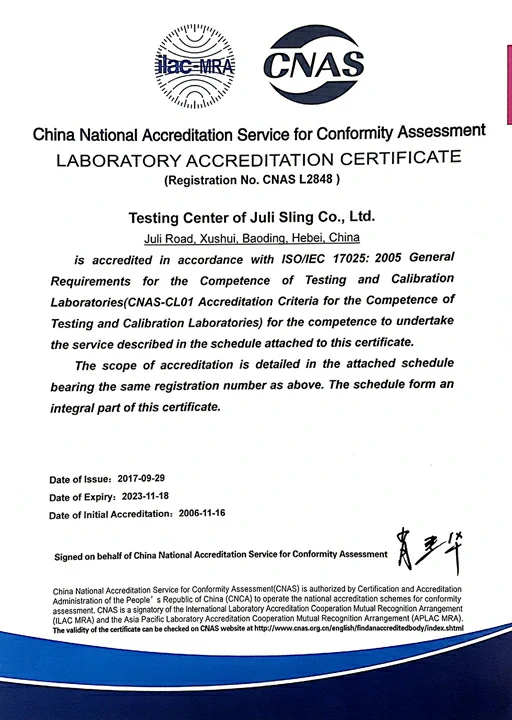

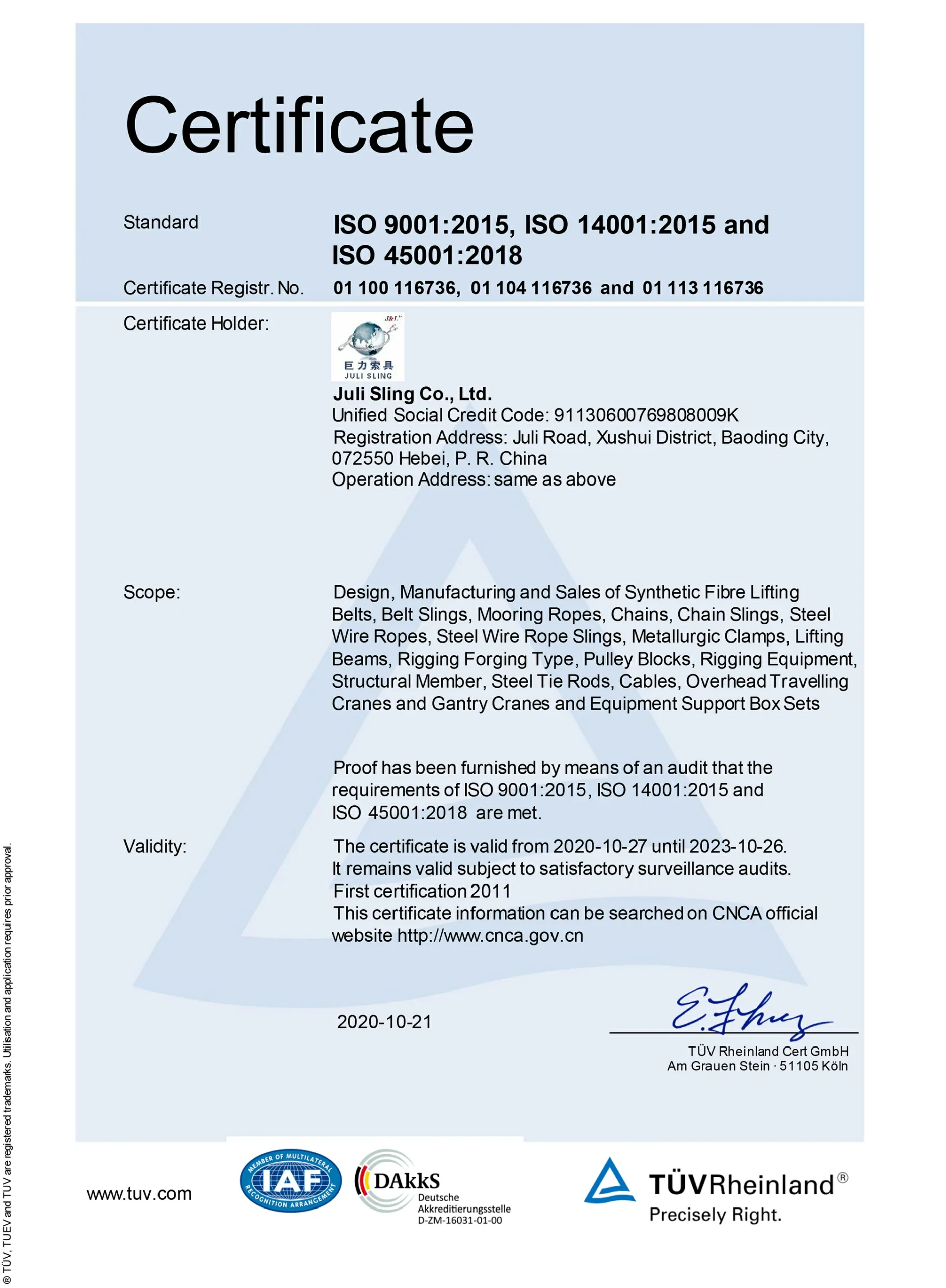

Juli Sling is a leading supplier of high-quality rigging products with 38 years of experience. As the only CNAS-approved test laboratory in the rigging industry, our Juli Sling Testing Center utilizes advanced electro-hydraulic servo horizontal tensile testing machines to provide comprehensive inspection services for metallic materials, synthetic fiber ropes, and lifting devices. We adhere to rigorous quality management standards, holding numerous certifications including ISO9001, ISO14001, and various international safety certifications. Our diverse product range includes polyester webbing slings, round slings, ratchet straps, steel wire ropes, and rigging equipment, earning us a reputation for reliability and efficiency in the market

Certifications

CE CNAS ISO

Production Process

Steel wire rope sling products including: Marine engineering series (grommet sling, high tension grommet sling,cable-laid sling), construction engineering series (pressed and casting sling), hoisting engineering series (pressed and spliced sling) and specialized slings. Production diameter range: 6mm to 570mm.

Export Cases

Main markets: America, Canada, Mexico, the Middle East, Africa, Australia, Russia, Europe, Japan, Vietnam, India, etc<br>

Exhibitions:2015.10 KORMARINE, 2016.11 OSEA, 2018.11 OSEA, 2019.11 ADIPEC, 2020.11 Bauma China, 2023.4 Neftegaz, 2024.3 OTC ASIA, 2024.5 OTC America.

FAQ

Q1: Are you factory or business company?

Juli Sling is an OEM&ODM manufacturer with nearly 38 years of history.

Focusing on research and development and manufacturing of rigging.

Q2: What is your terms of delivery?

Accept EXW, FOB, ClF, etc. lf you have any other choices orrequirements, we could negotiate it together to help you find the mostconvenient and favorable one.

Q3: How does your factory do regardingquality control?

Quality is priority. We always attach great importance to qualitycontrolling.Skillful workers care every details during the production,Strict quality testing in each process, Authoritative testing reports can beprovided for customer.

Q4: What payment method is available?

By T/T, L/C, Other methods can be negotiated together.