What are the different kinds of shackles: Choosing the Right Connector for Your Load

June 10, 2025

Shackles are the workhorses of any rigging or lifting system—silent connectors that keep slings, ropes, and hardware firmly linked under load. But “shackle” is a broad term encompassing many shapes, pin styles, finishes, and strength grades. Picking the right one for your application not only boosts efficiency, it keeps everyone safer. Here’s how to match shackle features to your job requirements.

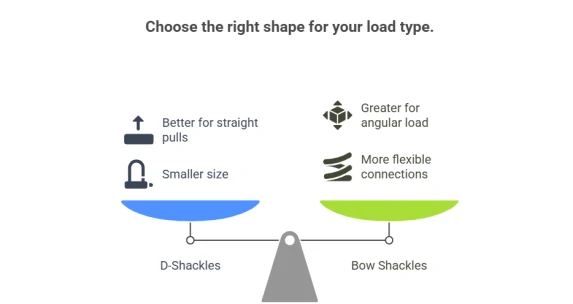

Shape: D-Shackle vs. Bow Shackle

When your pull is always in line with the pin—think straight-up lifts on a crane—D-shackles (or “Dees”) deliver the highest strength-to-weight ratio in the smallest footprint. Their narrow profile minimizes stress under pure tension, though they’re not designed to handle side loads.

Bow shackles (sometimes called anchor shackles) trade a bit of straight-pull capacity for versatility: the rounded “O” shape accommodates multiple sling legs and off-angle pulls without binding. If you frequently rig slings at shifting angles or need to clip on several attachments at once, bow shackles give you the extra room and bearing surface you need.

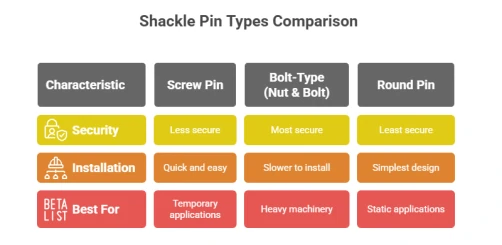

Pin Style: Quick-Change vs. Lock-Down

Your choice of pin can make or break safety under vibration or dynamic movement.

- Screw-Pin Shackles are hand-tightened and remove in seconds—perfect for temporary setups or sailboat rigging. Just remember to check them often: heavy vibration can loosen the threads.

- Bolt-Type Shackles (nut, bolt, plus cotter pin or safety clip) require a wrench to install, but resist vibration and accidental release. They’re the industry standard for overhead lifts, heavy machinery, or any scenario where pin security is critical.

- Round-Pin Shackles slide in place without threads. They’re the simplest and cheapest option, but friction alone won’t hold up under shock loads—reserve them for low-risk, static connections only.

Contact us to learn more about shackles: D Shackle; Flat Shackle; Large WLL Shackle With Circular Cross-Section and more.

Surface Treatment: Guarding Against Corrosion

The environment dictates your finish.

- Hot-Dip Galvanized shackles shine in marine or outdoor use: a thick zinc coating wards off rust and abrasion. After a heavy impact, inspect the steel underneath any chipped areas.

- Painted or Powder-Coated options let you color-code by Working Load Limit (WLL) and offer good protection in mild conditions—but their thinner layer wears faster in harsh environments.

- Stainless Steel (316 Grade) requires no coating and won’t corrode, even in saltwater—but it’s pricier, and threads can seize if you skip lubrication.

- Bare Alloy Steel with an oil film gives you the highest strength for size but demands regular cleaning and oiling to prevent rust.

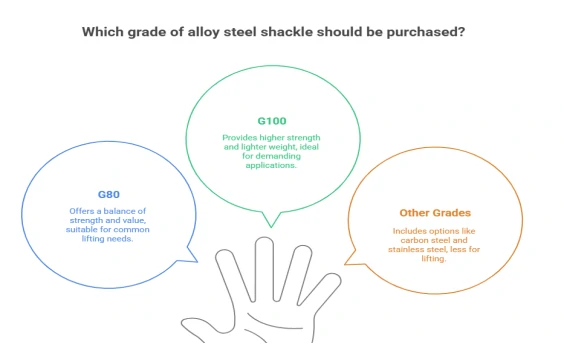

Strength & Grade: Reading the Markings

Shackle strength is categorized by grades, primarily defined by their Working Load Limit (WLL) relative to their size. Normally, the grades include:

- G80 (Grade 80): The most common grade for alloy steel lifting shackles. Offers a good balance of strength and value. WLL is typically 4 times the shackles diameter (e.g., a 1/2″ G80 shackle has a ~4.75 ton WLL).

- G100 (Grade 100): Higher strength alloy steel. Provides a higher WLL for the same physical size compared to G80. WLL is typically 5 times the diameter (e.g., a 1/2″ G100 shackle has a ~6.5 ton WLL). More expensive but allows for lighter, smaller shackles at the same WLL.

- Other Grades: G43 (Carbon Steel – lower strength, less common for lifting), G70 (Trucking/Transport Chain), Stainless Steel Grades (AISI 316, etc. – WLL varies by alloy).

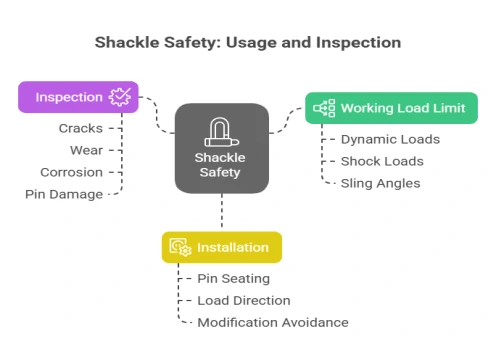

Safety First: Best Practices

No matter how well you’ve matched shackle shape, pin style, surface finish, and strength grade to your application, skipping thorough inspections or ignoring proper rigging procedures can still lead to serious hazards. Always confirm that the actual load—including any shock or dynamic forces—remains below the Working Load Limit (WLL) stamped on the shackle. Before each use, carefully examine both the shackle body and pin for cracks, distortion, thread wear, or hidden corrosion beneath coatings. When installing, make sure the pin is fully seated, that any nut and safety clip are properly secured, and that you apply load strictly along the pin axis to avoid side or cross loading. Never hammer pins into place, and under no circumstances drill, grind, or weld a shackle—altering its material integrity invites failure. By rigorously attending to these details every time, you ensure each lift is both efficient and, above all, safe.

Bringing It All Together

Choosing the right shackle means balancing shape, pin style, finish, and strength grade to match your specific lift, environment, and load profile. Always source products that meet ASME B30.26 or EN 13889 standards and come with traceable certification from reputable manufacturers. With the right hardware and strict adherence to inspection and rigging protocols, you’ll lift smarter, safer, and with confidence every time.